Washing machine with anti-scaling device between inner barrel and outer barrel

A washing machine and fouling technology, applied in other washing machines, washing devices, textiles and paper making, etc., can solve the problems of easy breeding of bacteria, falling off, affecting the washing effect, etc., so as not to change the original structure, solve the problem of fouling, and avoid the The effect of increasing working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

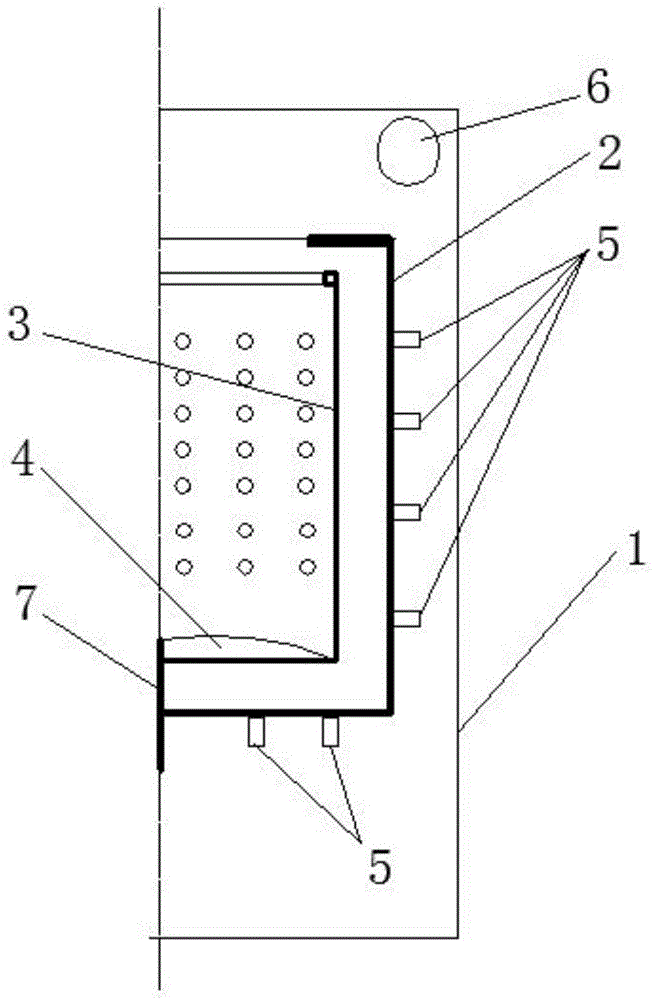

[0013] In order to describe the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. The schematic embodiments and descriptions of the present invention are used to explain the present invention, but are not intended to limit the present invention.

[0014] refer to figure 1 As shown, a washing machine with an anti-fouling device between the inner and outer tubs of the present invention includes a casing 1, an outer tub 2 arranged in the casing 1, an inner tub 3 arranged in the outer tub 2, a pulsator 4, and a transmission shaft 7 .

[0015] The present invention also includes an anti-fouling device, which includes an electromagnetic water valve 6, a water spray port 5 and a control circuit; the electromagnetic water valve 6 is arranged inside the shell 1, and the water inlet of the electromagnetic water valve 6 passes through a pipeline It is connected with the water inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com