A kind of concrete precision leveling operation vehicle for tunnel track bed construction operation

A technology for concrete and work vehicles, applied to roads, tracks, laying tracks, etc., to achieve the effects of improving operating efficiency, improving measurement and control accuracy, and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

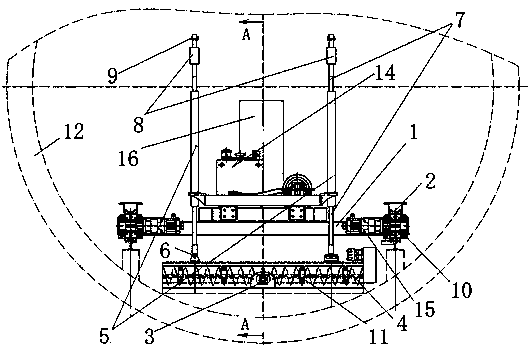

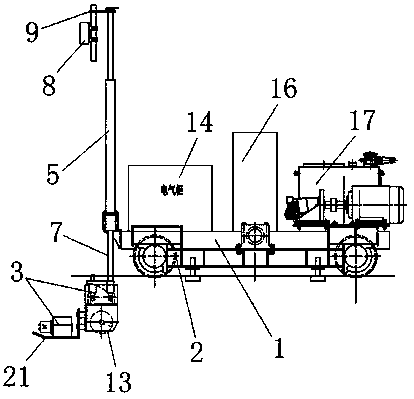

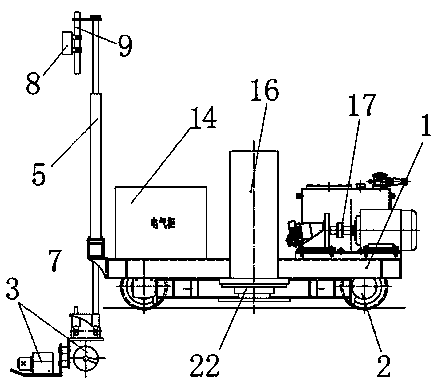

[0027] As can be seen from the accompanying drawings, the present invention relates to a concrete precision leveling operation vehicle for tunnel ballast construction operations, including a vehicle frame part 1, a running part 2 and a leveling system device 3, and the running part 2 is installed on the side of the vehicle frame part 1. On both sides, the leveling system device 3 is installed in the middle of the end of the frame part 1, and its characteristic is that the described leveling system device 3 is a precision leveling system device with a precision adjustment mechanism 4, through which the precision adjustment mechanism 4 Change the up and down and tilt positions of the leveling system device 3 to ensure that the precisely leveled road surface meets the requirements; the precision adjustment mechanism 4 includes two digital leveling hydraulic cylinders 5, and the two digital leveling hydraulic cylinders 5 are installed on On the frame part 1, the leveling system dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com