Ore-blast backfill synergetic mining method for partitioned rock drilling stage of inclined medium-thick ore body

A technology of thick ore body and mining method, applied in filling, ground mining, mining equipment, etc., can solve the problems of high mining cost, low degree of mechanization, low ore recovery rate, etc., to reduce the amount of mining and cutting engineering, increase the scale and efficiency, the effect of reducing filling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

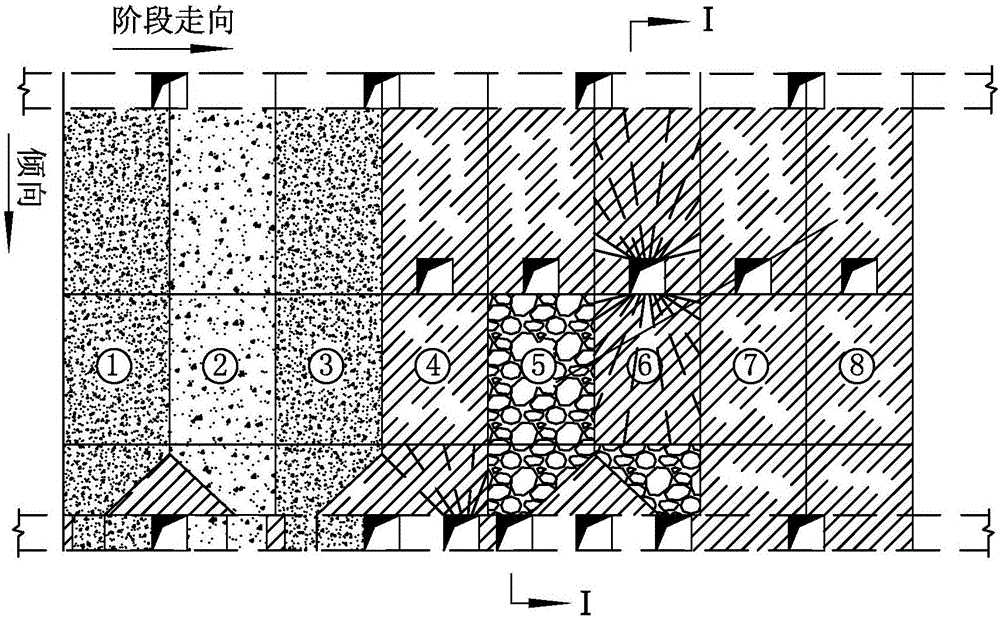

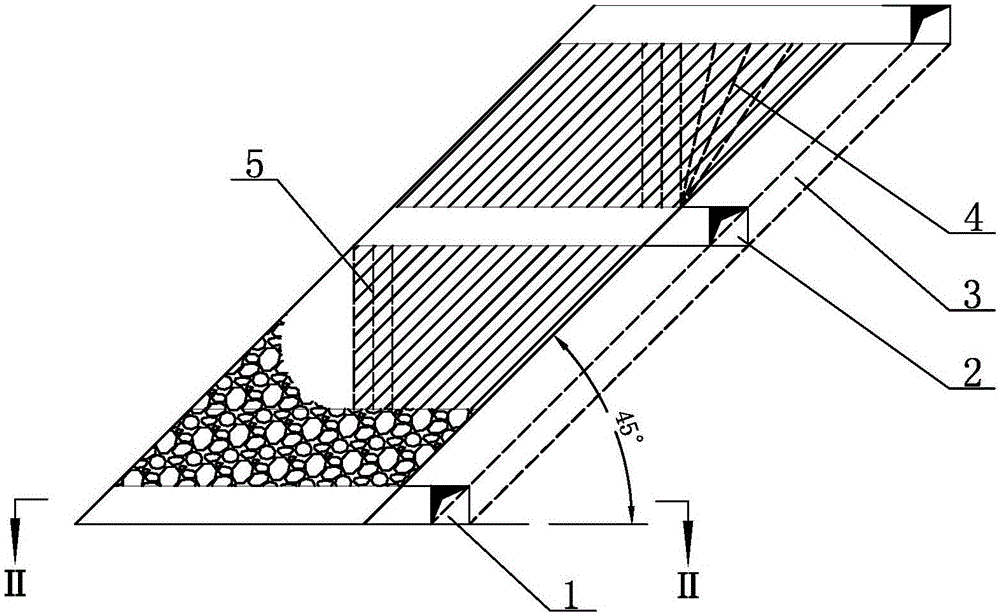

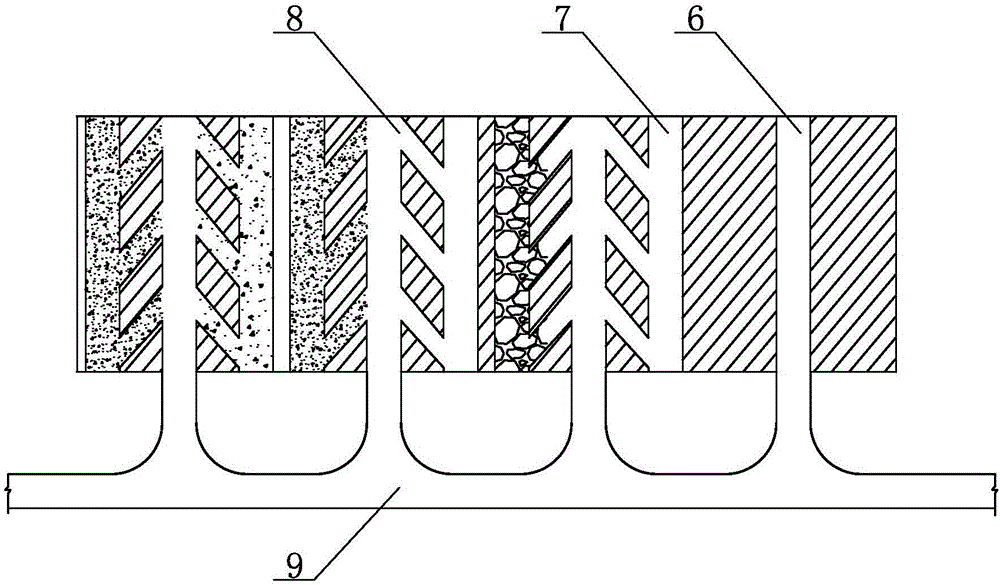

[0031]In the present invention, the inclined and medium-thick ore body is divided into rock-drilling stages and then filled with a collaborative mining method. In the stage, along the direction (that is, along the length direction), the mine houses and pillars are alternately arranged in strips, and a group of mine houses and pillars are one In the mine section, there are no spacers, top and bottom pillars, the vertical direction of the stope is arranged, the length of the stope is the thickness of the ore body, the mine room and the ore pillar are mined at intervals, and then filled, and the bottom of the stope is excavated. Mine roadway 6, mine outlet 8 and mine receiving roadway 7. During the mining process, the stope is divided into three rock-drilling areas to realize regional rock drilling and concentrated ore-receiving ore extraction: in the ore-receiving...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com