Damping device used for large device

A shock absorbing device and large-scale equipment technology, applied in the direction of non-rotational vibration suppression, etc., can solve problems such as deformation, and achieve good buffering effect, good shock resistance, and good deformation prevention effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

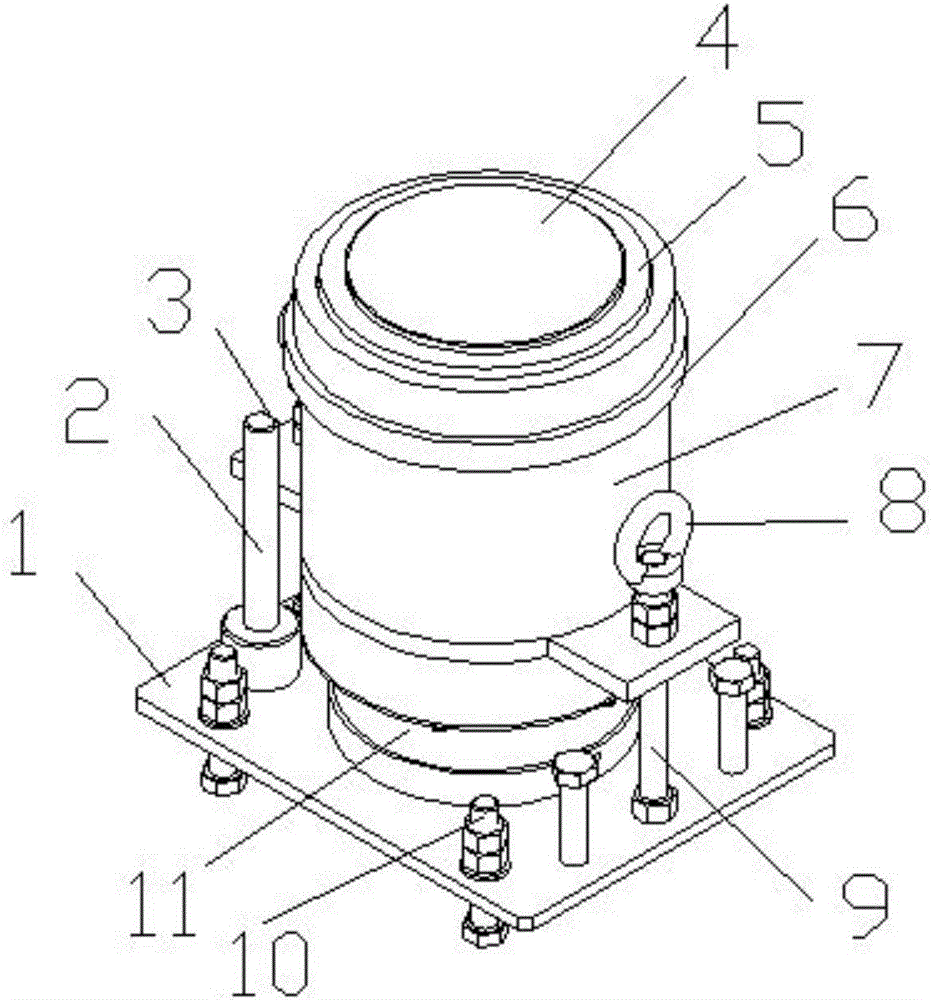

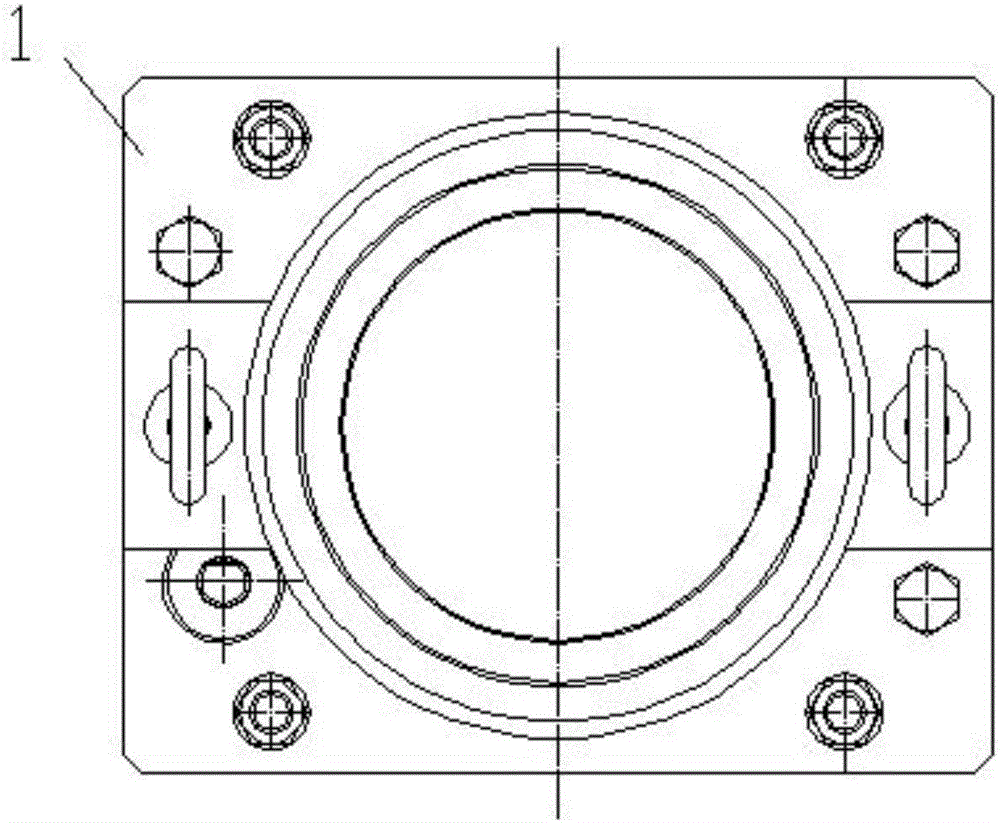

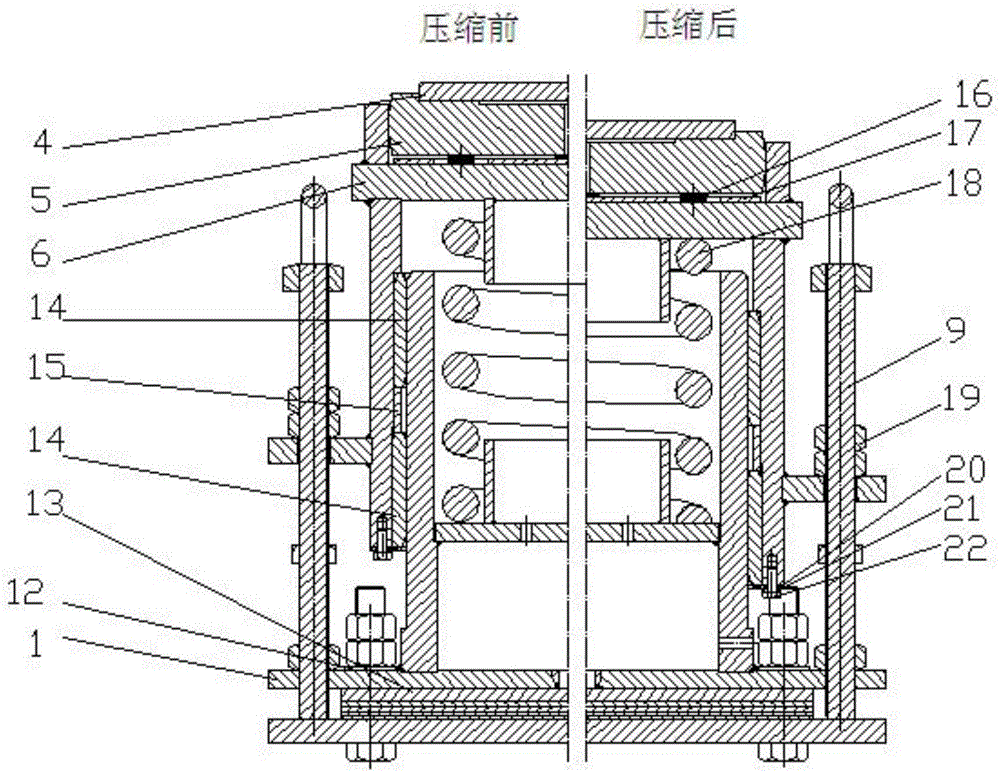

[0019] Embodiment one: if Figures 1 to 3 As shown, the present invention comprises a spring box body, the bottom of the spring box body is provided with a spring box base 1, the upper surface of the spring box base 1 is provided with studs 9 and ring nuts 198, and the four corners of the spring box base 1 are all provided with The second bolt 10, the top of the spring box base 1 is provided with a measuring piece 2 and an inner cylinder wall 11, the outer cylinder wall 11 is covered with an outer cylinder wall 7, and the two sides of the outer cylinder wall 7 are fixed by studs 9 and nuts 19, and the outer cylinder The top of the wall 7 is provided with a spring box top wall, the top of the spring box 6 is provided with a twist cover 5, the twist cover 5 is provided with a slide plate 4, and a slip ring 14 is provided between the inner cylinder wall 11 and the outer cylinder wall 7. The middle part of the slip ring 14 is provided with a guide ring 15, and the inside of the sp...

Embodiment 2

[0021] Embodiment 2: The present invention comprises a spring box body, a spring box base 1 is arranged at the bottom of the spring box body, studs 9 and ring nuts 198 are arranged on the upper surfaces of both sides of the spring box base 1, and four corners of the spring box base 1 are provided with There is a second bolt 10, a measuring piece 2 and an inner cylinder wall 11 are arranged above the spring box base 1, and an outer cylinder wall 7 is set on the outer side of the inner cylinder wall 11, and the two sides of the outer cylinder wall 7 are fixed by studs 9 and nuts 19. The top of the cylinder wall 7 is provided with a spring box top wall, the spring box top 6 is provided with a twist cover 5, the twist cover 5 is provided with a slide plate 4, and a slip ring 14 is provided between the inner cylinder wall 11 and the outer cylinder wall 7, so that The middle part of the slip ring 14 is provided with a guide ring 15, the inside of the spring box body is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com