Energy adjusting system

An energy adjustment, pump wheel technology, applied in the direction of fluid transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of increasing weight, occupying effective space, low efficiency and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

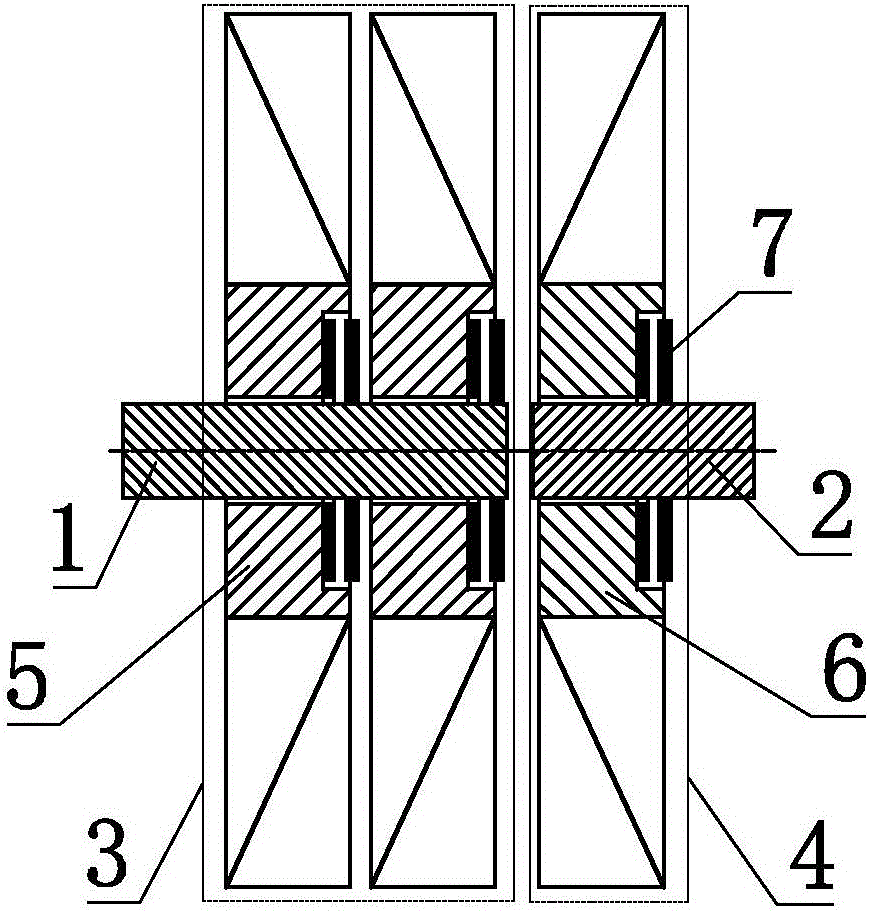

[0047] Such as figure 1 The energy adjustment system shown includes a rotating shaft A1, a rotating shaft B2, a pump wheel group 3, and a turbine group 4. The pump wheel group 3 includes more than two pump wheels 5, and the turbine group 4 includes more than one turbine 6. The pump wheel group 3 and the turbine group 4 are arranged correspondingly, at least one of the pump wheels 5 in the pump wheel group 3 is drivingly connected to the rotating shaft A1 via a clutch 7, and at least one of the turbine groups 4 The turbine 6 is in driving connection with the rotating shaft B2 via a clutch 7.

[0048] As an alternative embodiment, this embodiment may further selectively choose to connect the pump wheel set 3 and the turbine set 4 in series.

[0049] As a transformable implementation, this embodiment can further selectively choose to make at least one of the pump wheels 5 in the pump wheel group 3 drive-connected with the rotating shaft B2 via a clutch 7, and the turbine group 4 At l...

Embodiment 2

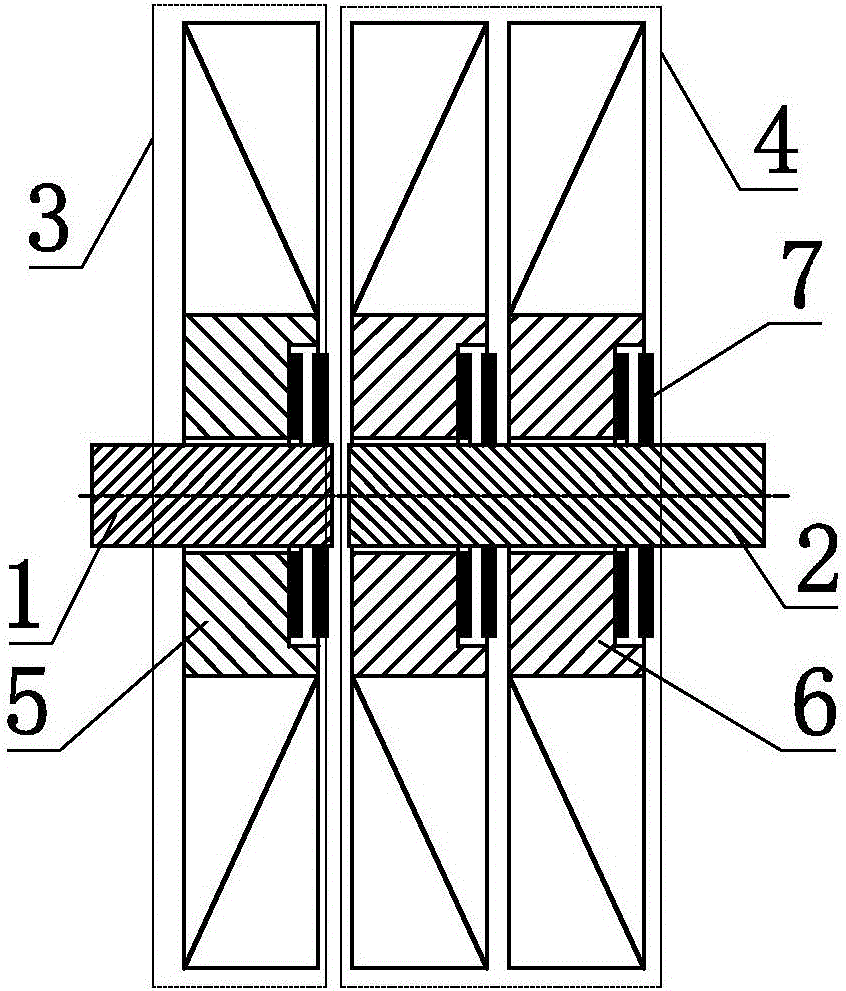

[0051] Such as figure 2 The energy adjustment system shown includes a rotating shaft A1, a rotating shaft B2, a group of pump wheels 3, and a group of 6 turbines 4. The pump wheel group 3 includes more than one pump wheel 5, and the turbine group 4 includes more than two turbines 6, The pump wheel group 3 and the turbine group 4 are arranged correspondingly, at least one of the pump wheels 5 in the pump wheel group 3 is in transmission connection with the rotating shaft A1 via a clutch 7, and at least one of the turbine groups 4 The turbine 6 is in driving connection with the rotating shaft B2 via a clutch 7.

[0052] As an alternative embodiment, this embodiment may further selectively choose to connect the pump wheel set 3 and the turbine set 4 in series.

[0053] As a transformable implementation, this embodiment can further selectively choose to make at least one of the pump wheels 5 in the pump wheel group 3 drive-connected with the rotating shaft B2 via a clutch 7, and the t...

Embodiment 3

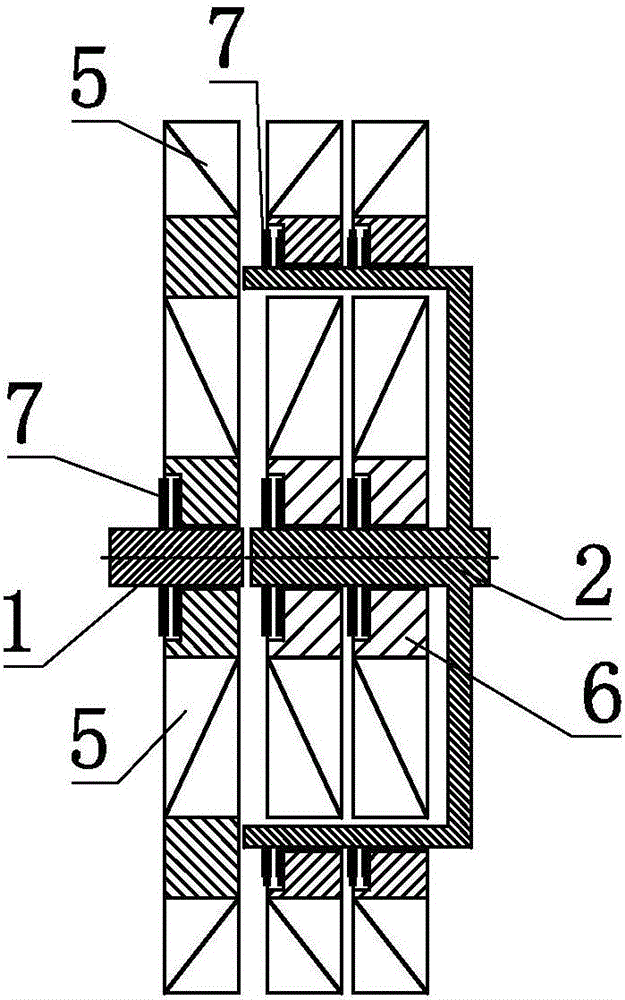

[0055] Such as image 3 In the energy adjustment system shown, on the basis of Embodiment 1, the pump wheels 5 are further arranged in series.

[0056] As a transformable embodiment, embodiment 1 or 2 and its transformable embodiments can further selectively connect the pump wheels 5 in series, or the pump wheels 5 in parallel ( Figure 4 The energy adjustment system shown), or the pump wheel 5 mixed connection setting ( Figure 5 Energy adjustment system shown).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com