Two-position three-way rotating disc type reversing valve

A rotary disc type reversing valve, two-position three-way technology, applied in the direction of sliding valve, valve details, valve device, etc., can solve the problems of difficult manufacturing, complex structure, difficult sealing, etc., to achieve compact structure, stable operation, Easy-to-process effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Further description will be given below through specific embodiments and in conjunction with the accompanying drawings.

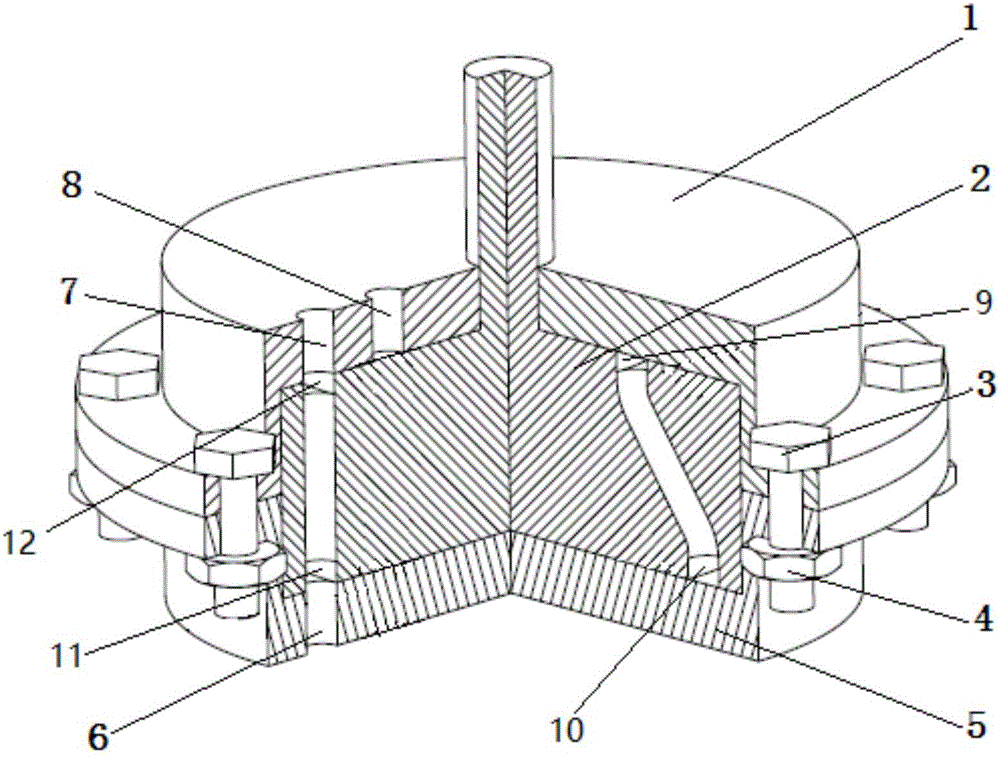

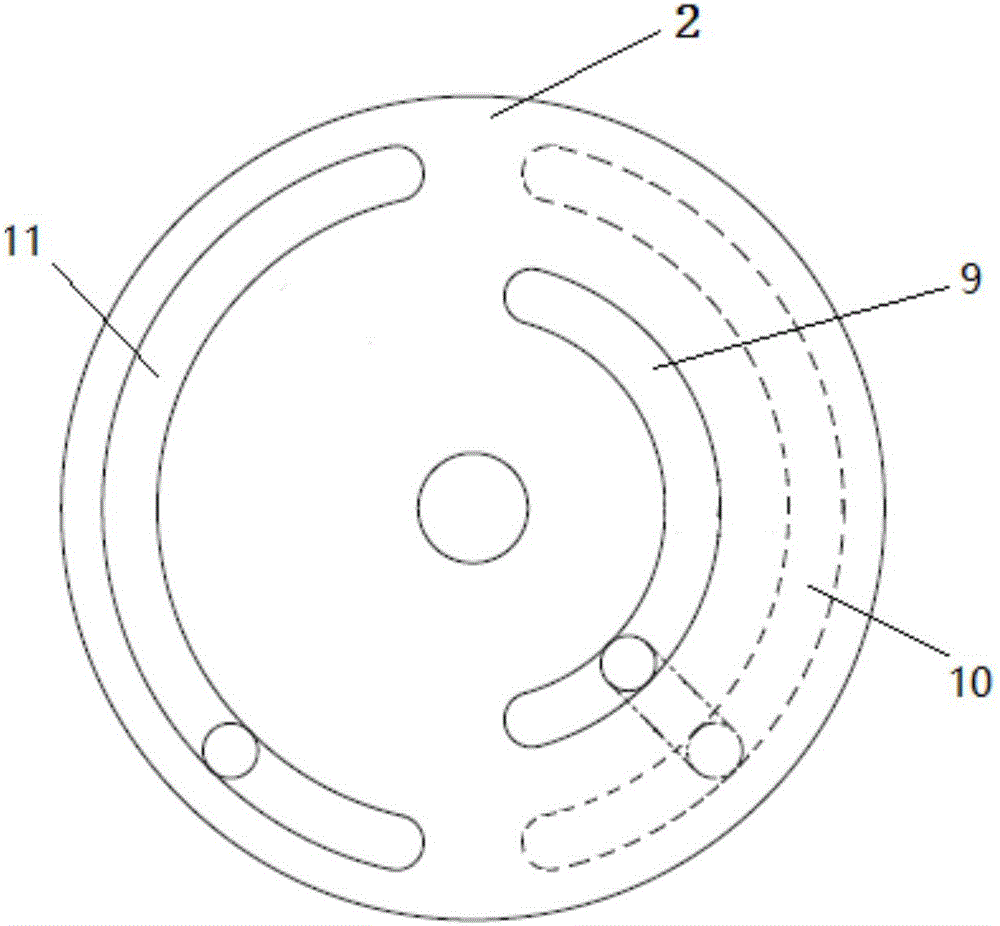

[0020] The main structure of the present invention includes an upper valve body 1, a lower valve body 5, and a valve disc 2, and the upper valve body 1 and the lower valve body 5 are integrally connected and fixed on the base. The upper valve body 1 and the lower valve body 5 form a disc-shaped cavity inside to accommodate the valve disc 2. The valve disc 2 fits with the upper valve body 1 and the lower valve body 5 with a small gap and can rotate flexibly around the axis.

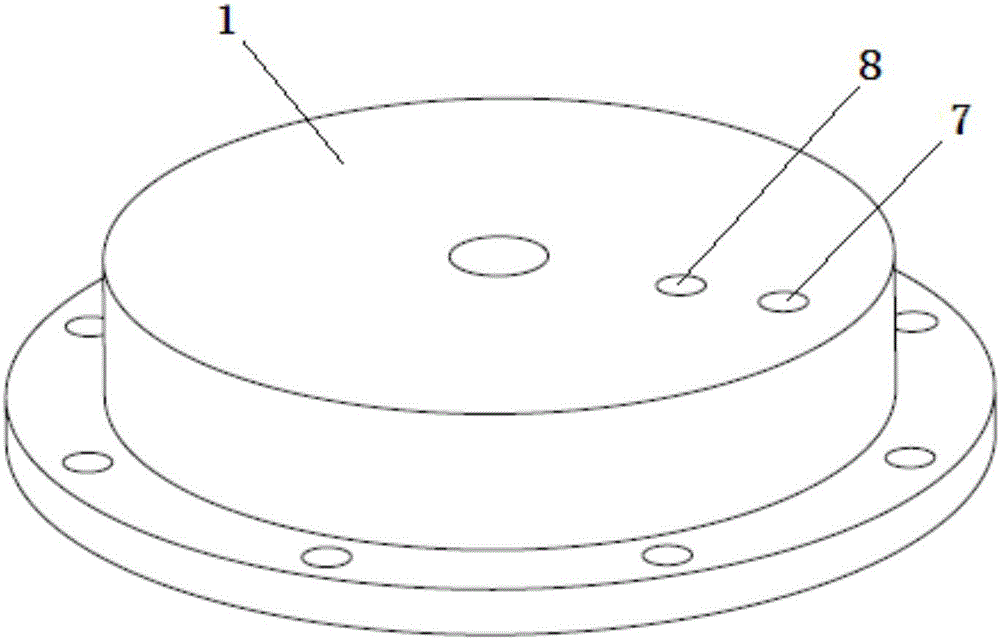

[0021] The upper valve body 1 is generally disc-shaped from the outside, with a cylindrical cavity inside, and two liquid flow ports, oil port B7 and oil port C8, are opened on the upper end surface for oil in and out; the axial center position of the upper end surface There is a turntable hole, and the rotating shaft of the valve disc 2 protrudes from the turntable hole; the ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com