Connector adaptive plugging device

A self-adaptive, connector technology, applied in the direction of the launch device, can solve the problems of poor reliability, low operating efficiency, and high work intensity of assembly personnel, and achieve the effect of reducing work intensity, simple structure, and eliminating uncertain factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

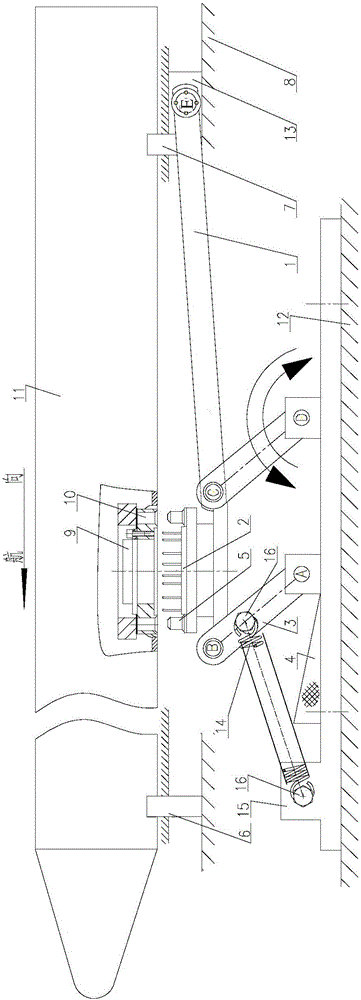

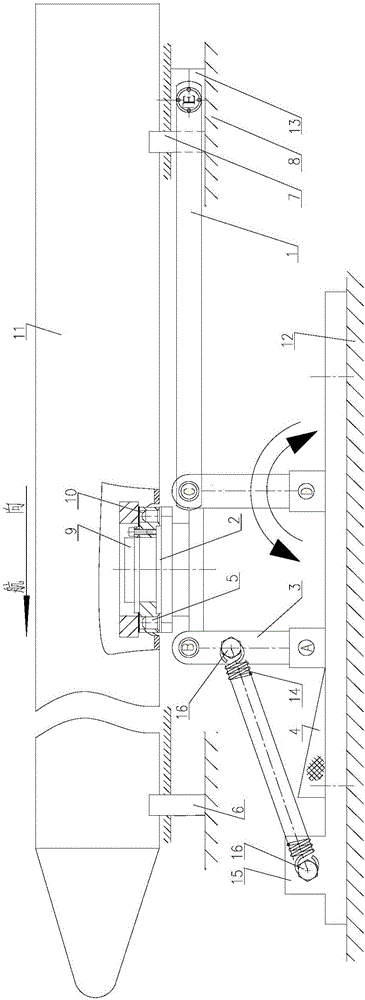

[0018] The following combination Figure 1 ~ Figure 2 , a preferred embodiment of the present invention is described in detail.

[0019] Such as figure 1 and figure 2 As shown, the connector adaptive mating device provided by the present invention realizes the automatic connection and separation between the missile 11 and the launch box 12, including: a four-bar linkage mechanism 3 fixedly arranged on the launch box 12 through the installation base 15 The linkage mechanism is connected between the four-bar linkage mechanism 3 and the missile 11; the plug 2 is fixedly arranged on the four-bar linkage mechanism 3; the socket 9 is fixedly arranged on the missile 11, and the The position of the socket 9 corresponds to the position of the plug 2; when the missile 11 is loaded or fired, the interlocking mechanism drives the plug 2 on the four-bar linkage mechanism 3 to self-fit or automatically separate from the socket 9 arranged on the missile 11 .

[0020] The linkage mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com