How to use an auxiliary device for calibrating dynamic torque assembly tools

A dynamic torque and assembly tool technology, applied in the field of measurement, can solve the problem of difficult to guarantee the quality of bolted connections, and achieve the effect of satisfying daily production inspection, reducing errors, improving stability and coaxiality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

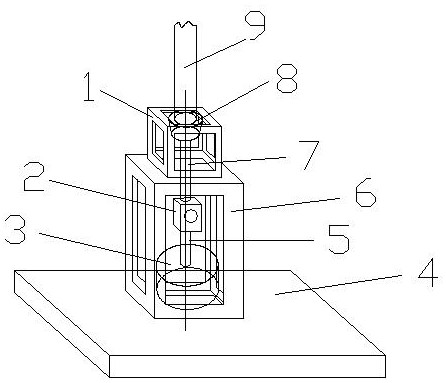

[0027] The present invention will be further described below through embodiments and in conjunction with the accompanying drawings. The present invention adopts the following scheme to achieve the above object: the auxiliary device for calibrating the dynamic torque assembly tool includes: guide frame 1, standard dynamic torque sensor 2, test nut 3, base 4, secondary adapter connector 5, main support frame 6, main adapter Equipped with connector 7 and radial thrust bearing 8; connect the guide frame 1, main support frame 6 and base 4 through screws from top to bottom, install the radial thrust bearing 8 on the guide frame 1, and install the test nut 3 on the main support At the bottom of the frame 6, the main adapter connector 7 connects the standard dynamic torque sensor 2 and the output shaft 9 of the calibrated dynamic torque assembly tool, and the secondary adapter connector 5 connects the standard dynamic torque sensor 2 and the test nut 3.

[0028] In the process of desi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com