Rapid slice trimming mechanism for slicing machine

A slicer and fast technology, applied in the direction of sampling devices, etc., can solve problems such as inconvenience of use, and achieve the effect of convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

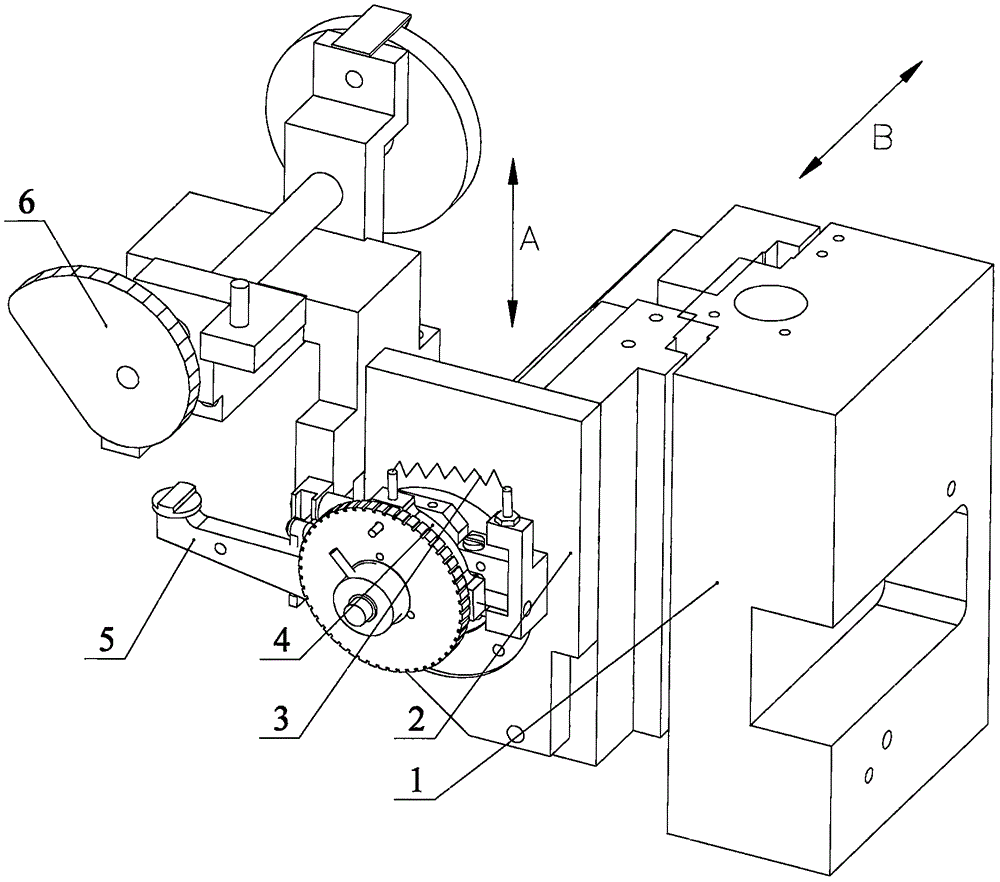

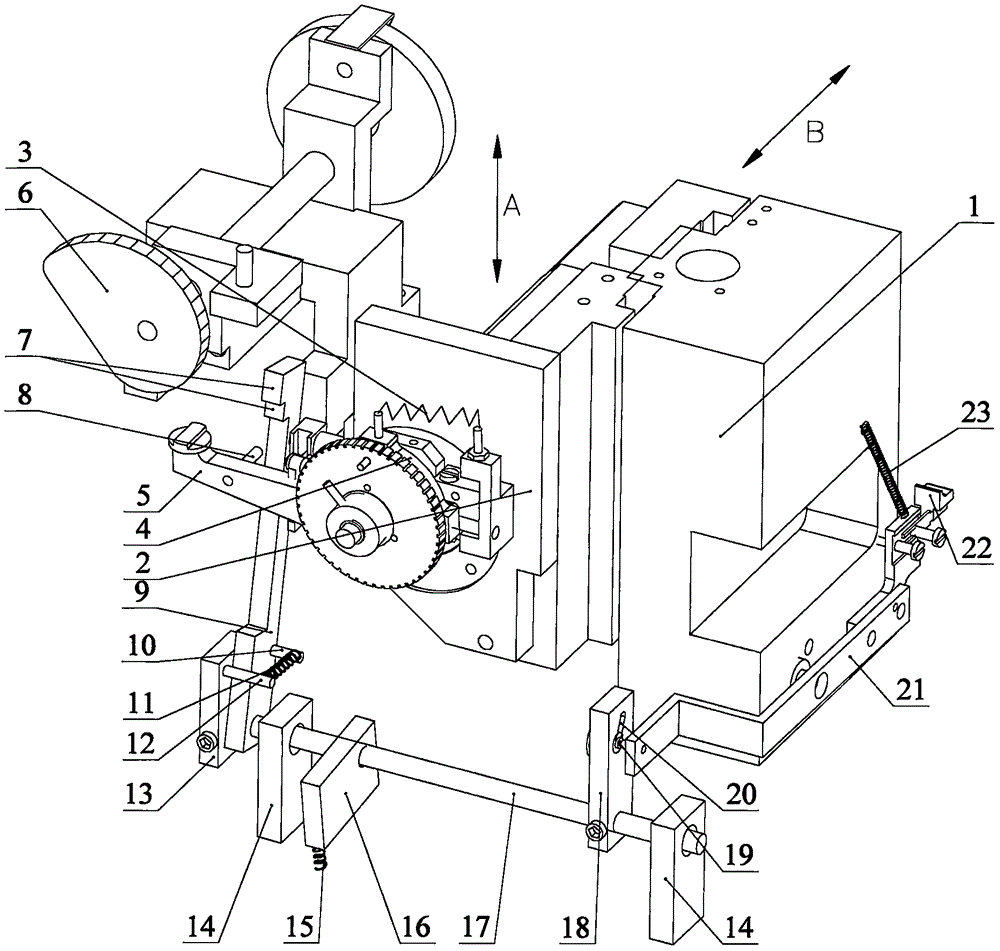

[0035] Below in conjunction with each accompanying drawing, the present invention is described in detail.

[0036] Such as figure 2 and 3 As shown, a slicer with a fast trimming mechanism, the slicer includes the structure mentioned in the background technology, that is, it includes a machine base 1, a moving seat 2, a return spring 3, a one-way bearing 4, a raised portion 5 and a feeding Eccentric disc 6, etc., fast film trimming mechanism includes:

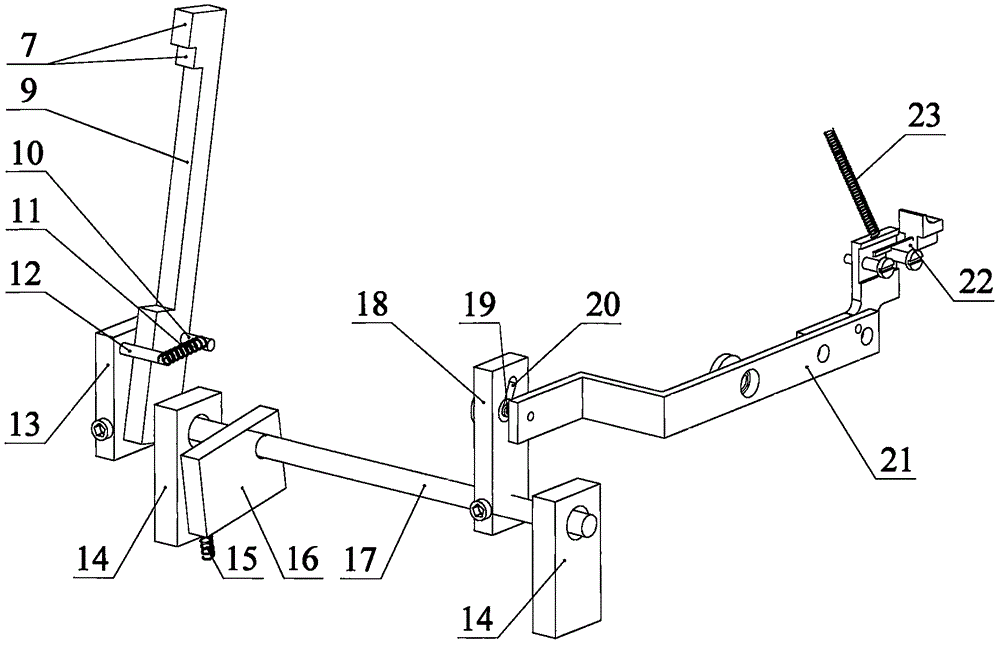

[0037] The rotating shaft 17 is installed on the microtome in rotation;

[0038] The limit rod 9 is relatively fixed to the rotating shaft, and the limit rod has a plurality of limit projections 7, which are used to cooperate with the raised portion 5 of the slicer to control the feed rate;

[0039] The control assembly cooperates with the rotating shaft 17 and is used to control the rotation of the rotating shaft 17 so that the limit bump 7 cooperates with the raised portion 5;

[0040] The elastic reset member is used to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com