Nuclear reactor control rod bundle assembly in-service inspection device decontamination tool

A technology for controlling rod bundles and nuclear reactors, applied in nuclear engineering, radioactive purification, etc., can solve the problems of long time, high labor intensity of personnel operation, high exposure dose, etc., achieve reduced operation time, wide application range, and high decontamination level Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

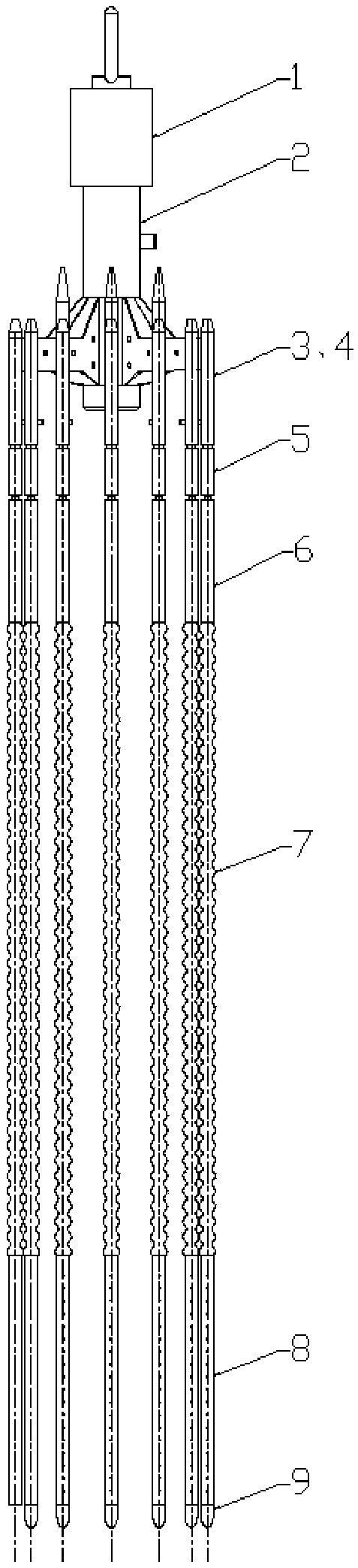

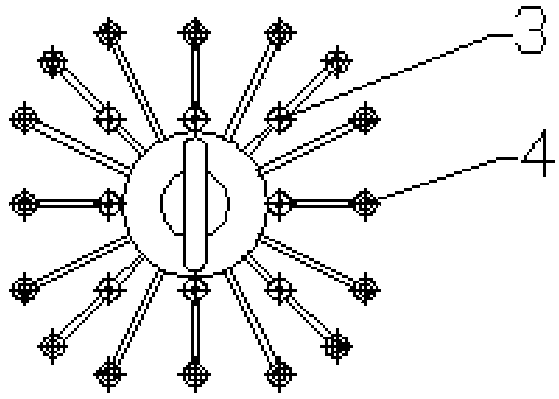

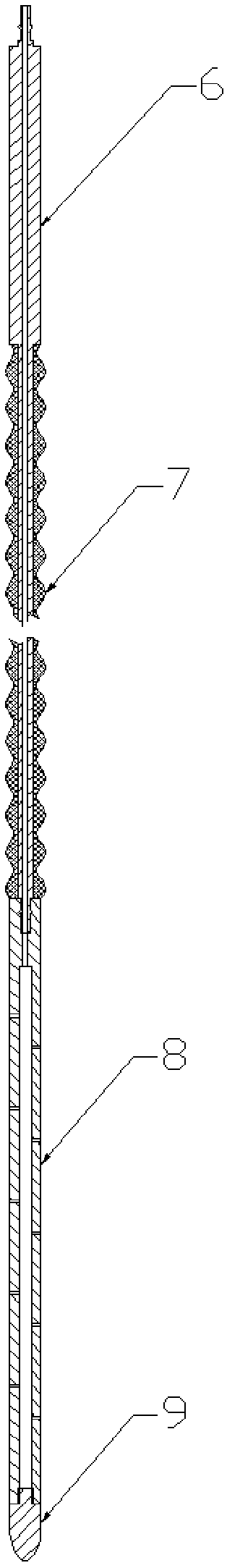

[0021] In this example, if figure 1 As shown, the decontamination tool for the in-service inspection device of the nuclear reactor control rod bundle assembly includes a suspension ring 1, a planet carrier 2 fixed below the suspension ring 1, a connecting rod installed on the planet carrier 2, and a connecting rod connected to the connecting rod. The decontamination rod on the top, the guide head 9 connected to the lower end of the decontamination rod, the water pump that provides low-pressure water flow for the decontamination rod, the decontamination rod is hollow, and it is divided into a wiping section 6 and a flushing section 8 from top to bottom , The wiping section 6 is covered with a wiping sponge 7, and the side wall of the washing section 8 is provided with a water outlet hole, and the diameter of the water outlet hole is 0.5-2mm. In order to protect the equipment and prevent damage to the equipment by the high-pressure water flow, on the premise of having a wiping s...

Embodiment 2

[0028] In this embodiment, the decontamination tool for the in-service inspection device of the nuclear reactor control rod bundle assembly includes a suspension ring 1, a planet carrier 2 fixed below the suspension ring 1, a connecting rod installed on the planet carrier 2, and a connecting rod connected to the The decontamination rod on the connecting rod, the guide head 9 connected to the lower end of the decontamination rod, the water pump that provides low-pressure water flow for the decontamination rod, and the air pump that feeds air into the planet carrier, the decontamination rod is hollow, and its From top to bottom, it is divided into a wiping section 6 and a rinsing section 8. The wiping section 6 is covered with a wiping sponge 7, and the side wall of the rinsing section 8 is provided with a water outlet hole, and the diameter of the water outlet hole is 0.5-2mm.

[0029] The inside of the planet carrier 2 is provided with a flow channel communicating with the insi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com