Transferring head used for transferring micro-components and micro-component transferring method

A technology of micro-components and components, which is applied in the field of transfer of transposition heads and micro-components, and can solve problems such as thermal budget constraints and performance degradation of micro-components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

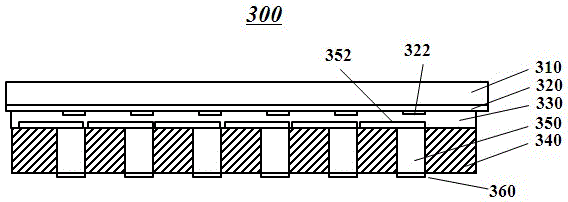

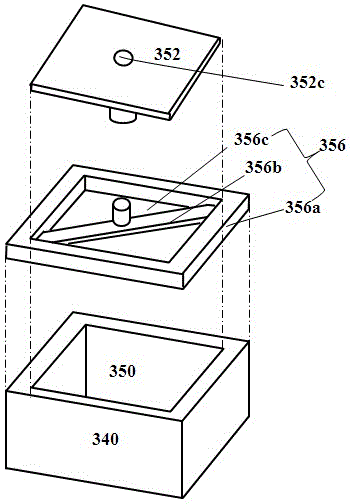

[0039] figure 1 Showing a first preferred embodiment of the present invention, a transpose head 300 for transferring micro components includes: a cavity 330 , an array of switching elements, an array of vacuum paths 350 and an array of suction nozzles 360 . Wherein, the switch assembly array is disposed on the upper side of the cavity 330 , the vacuum path array 350 is disposed on the lower side of the cavity 330 , and there is a space between them to form the cavity. The vacuum path array communicates with the cavity 330, and controls the opening / closing of each vacuum path 350 through the valve, and controls the valve of each vacuum path through the switch assembly to control the opening or closing of the vacuum path to extract the required micro element.

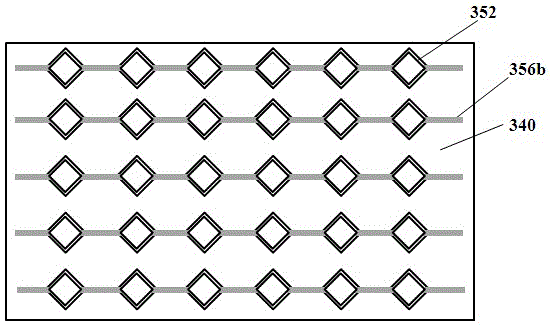

[0040] Please see figure 2 The switch assembly array is composed of a CMOS storage circuit layer 310 and an address electrode layer 320 located below it. An address electrode array is arranged on the address electrode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com