Integrated energy-saving motor with single-phase input and three-phase output function

An integrated, three-phase technology, applied in the output power conversion device, AC power input conversion to AC power output, AC motor control and other directions, can solve the trouble of inverter wiring, poor torque characteristics of single-phase motor, overload Poor capacity and other problems, to achieve the effect of controllable start-up time, adjustable output frequency, and wide input voltage range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

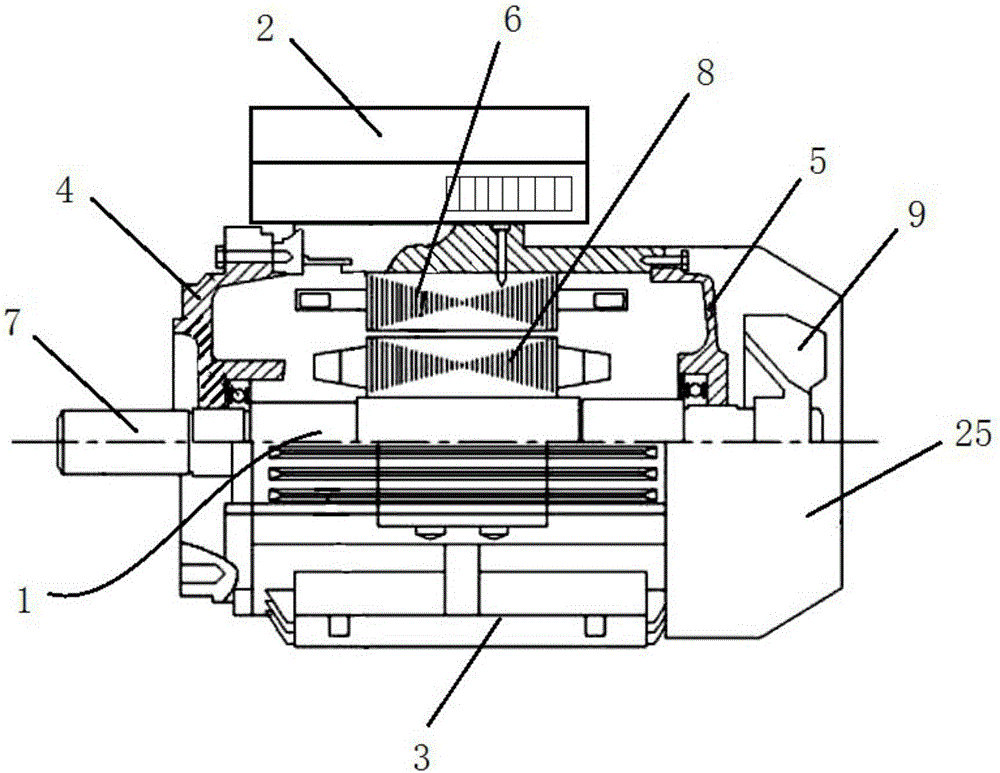

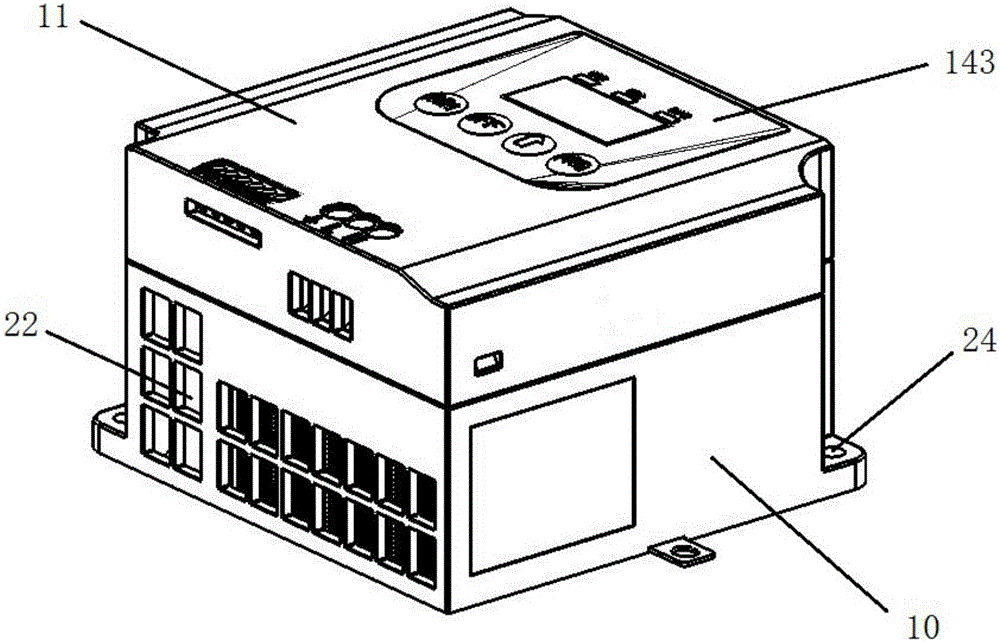

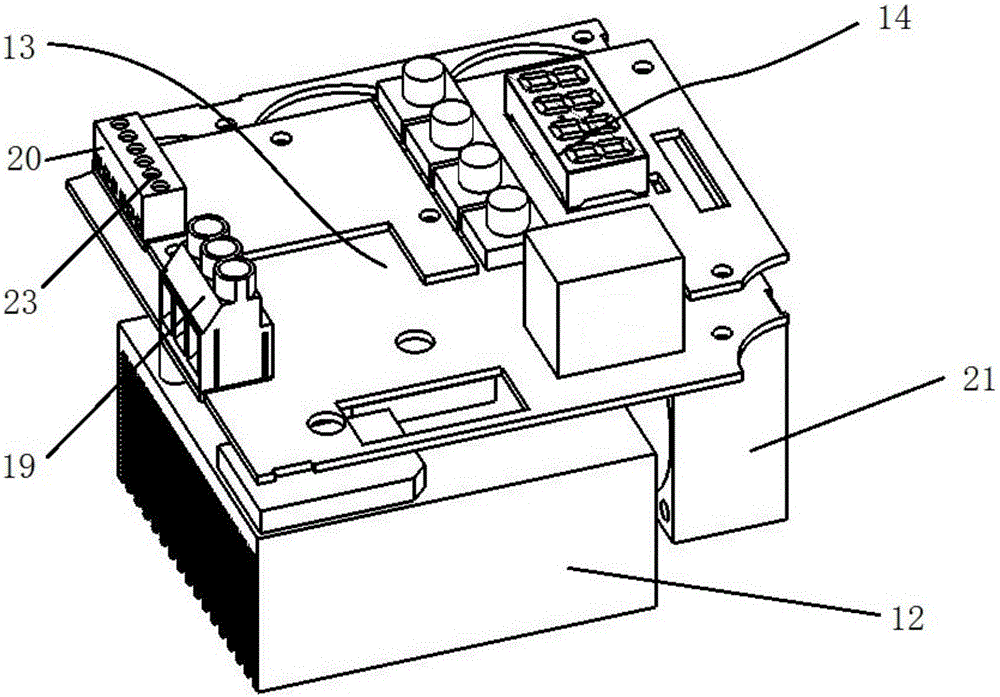

[0029] An integrated energy-saving motor with single-phase input and three-phase output functions described in the present invention, such as figure 1 As shown, it includes: a three-phase asynchronous motor 1 and a frequency converter 2 arranged on the three-phase asynchronous motor 1 and connected to it; wherein, the three-phase asynchronous motor 1 includes a frame 3 and two The front end cover 4 and the rear end cover 5 at the end, the inside of the base 3 is provided with a stator winding 6 and a rotating shaft 7; the rotor 8 is sleeved on the rotating shaft 7; The fan 9 on 7; the outside of the fan 9 is provided with a windshield 25; as figure 2 , image 3 , Figure 4 As shown, the frequency converter 2 includes a housing 10 and an upper cover 11 made of ABS resin; the housing 10 is provided with a heat sink 12, a control circuit 13 and a display module 14; the control circuit 13 is set Above the heat sink 12; the display module 14 is arranged on the control circuit 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com