Food nanocrystallization cold sterilization method and system

A nanonization and cold sterilization technology, which is applied in food preservation, food science, application, etc., can solve the problems of easily destroying the nutritional value of food, difficulty in realizing nanonization, and wide distribution of food particles, so as to improve the efficiency of biological enzymes and improve Organoleptic qualities, effects of adding finesse and original flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

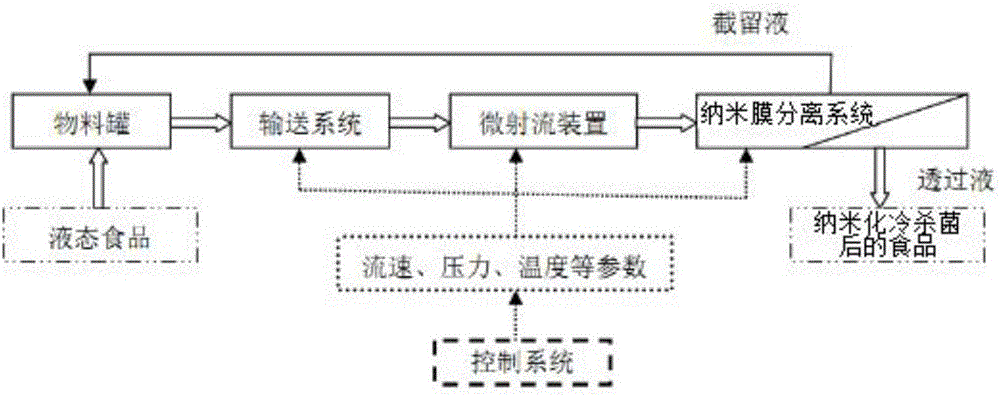

[0025] A kind of food nano cold sterilization system of this embodiment, its connection relationship structural diagram is as follows figure 1 As shown, it includes a material tank, a conveying system, a microfluidic device and a nano-membrane separation system connected in sequence; the nano-membrane separation system is provided with a retentate outlet and a permeate outlet, and the retentate outlet is connected to the material tank; the nanometerization The cold sterilization system is also equipped with a control system, which is used to control the flow rate, pressure, temperature and other parameters of the delivery system, micro-fluidic device and nano-membrane separation system.

[0026] Using the above-mentioned system to carry out a nano-scale cold sterilization method for food, including the following steps:

[0027] Pick eight to nine mature fresh watermelons, and obtain clear watermelon juice by taking scoops, crushing, squeezing, filtering, etc. After testing, th...

Embodiment 2

[0032] Adopt the system of embodiment 1 to carry out the method for nanometerized cold sterilization of food, comprising the steps:

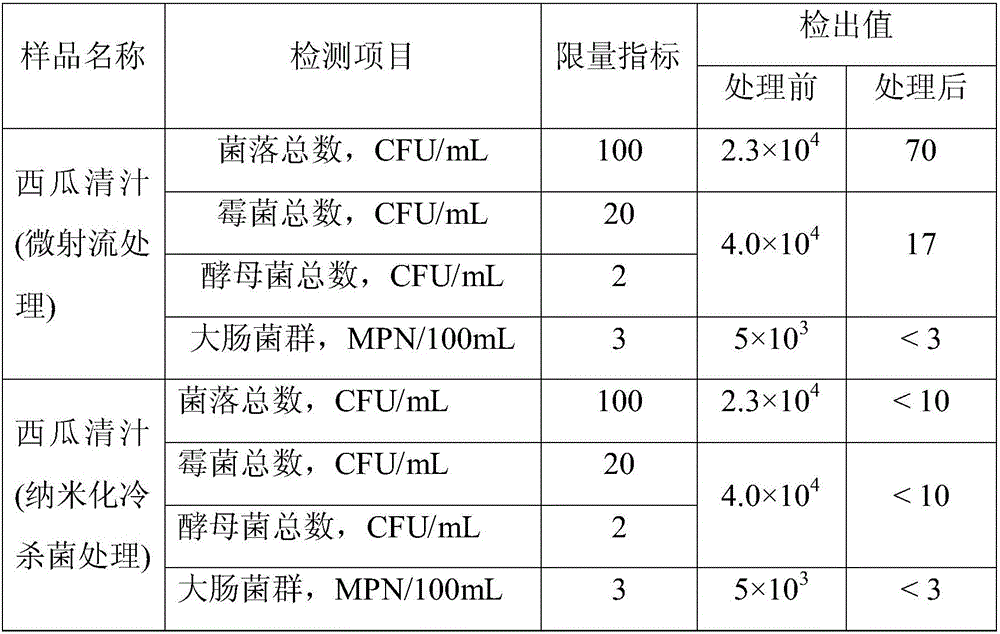

[0033] Pick eight to nine mature fresh watermelons, and obtain clear watermelon juice by taking scoops, crushing, squeezing, filtering, etc. After testing, the total number of initial bacterial colonies reaches 2.3×10 4 cfu / mL, the total number of mold and yeast colonies all reached 4.0×10 4 cfu / mL, the number of coliform bacteria is 5×10 3 cfu / mL. Inhomogeneous particles can be seen in the liquid, and it is accompanied by obvious stratification after standing for a long time. Add clear watermelon juice into the material tank in an aseptic manner, enter the micro-fluidic device through the conveying system, set it to 300MPa ultra-high pressure homogenization, control the temperature of the material at 4-6°C through the control system, perform micro-fluidic treatment for 10 minutes, and pass through the nano Membrane separation system filtrati...

Embodiment 3

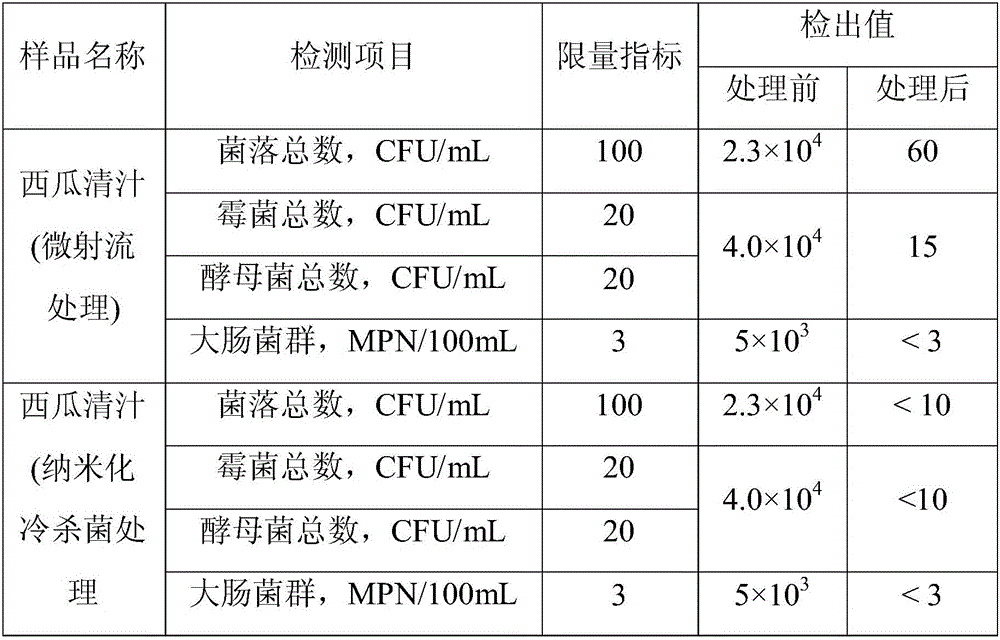

[0037] Adopt the system of embodiment 1 to carry out the method for nanometerized cold sterilization of food, comprising the steps:

[0038] Strawberries were crushed, squeezed and filtered to obtain strawberry juice. After testing, the total number of initial colonies reached 3.2×10 4 cfu / mL, the total number of mold and yeast colonies all reached 2.5×10 4 cfu / mL, the number of coliform bacteria is 4.5×10 3 cfu / mL. Inhomogeneous particles can be seen in the liquid, and it is accompanied by obvious stratification after standing for a long time. Add strawberry juice to the material tank in an aseptic manner, enter the micro-fluidic device through the conveying system, set it to 400MPa ultra-high pressure homogenization, control the temperature of the material at 4-6°C through the control system, perform micro-fluidic treatment for 10 minutes, and pass through the nano Membrane separation system filtration, the nano-membrane separation system uses a filter pore size of 200nm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com