Shoe washing machine

A shoe washing machine and chassis technology, applied in the field of shoe washing machines, can solve the problems of wasting water, difficult to clean, tearing, etc., and achieve the effect of saving water resources and convenient fixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

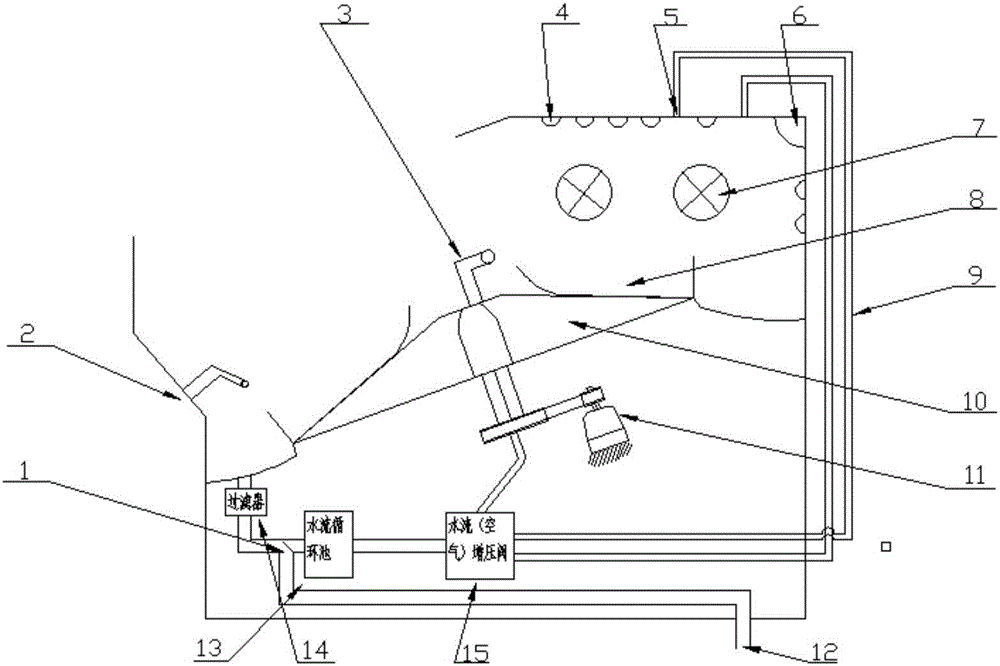

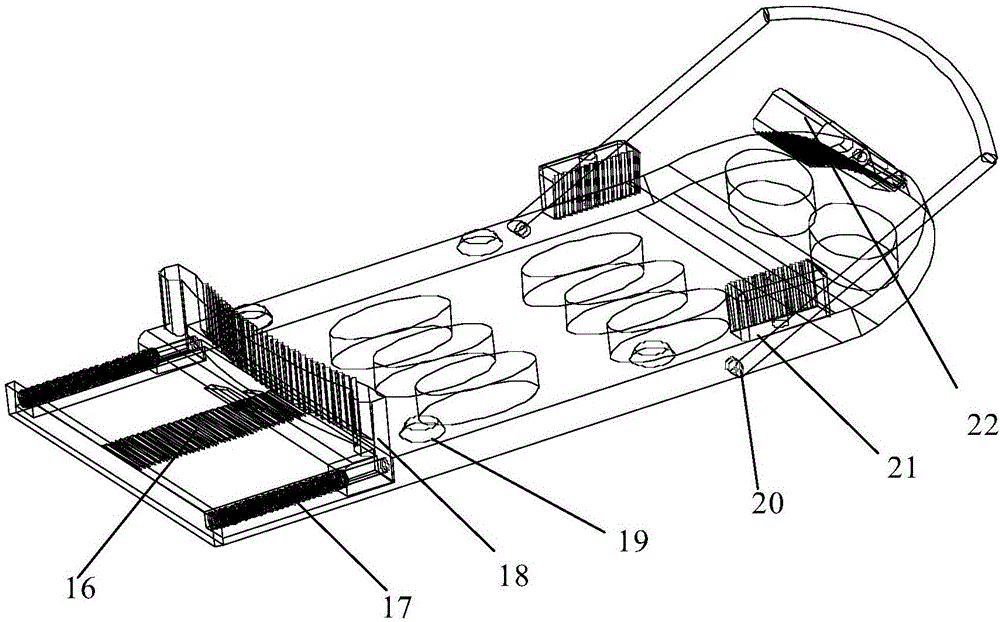

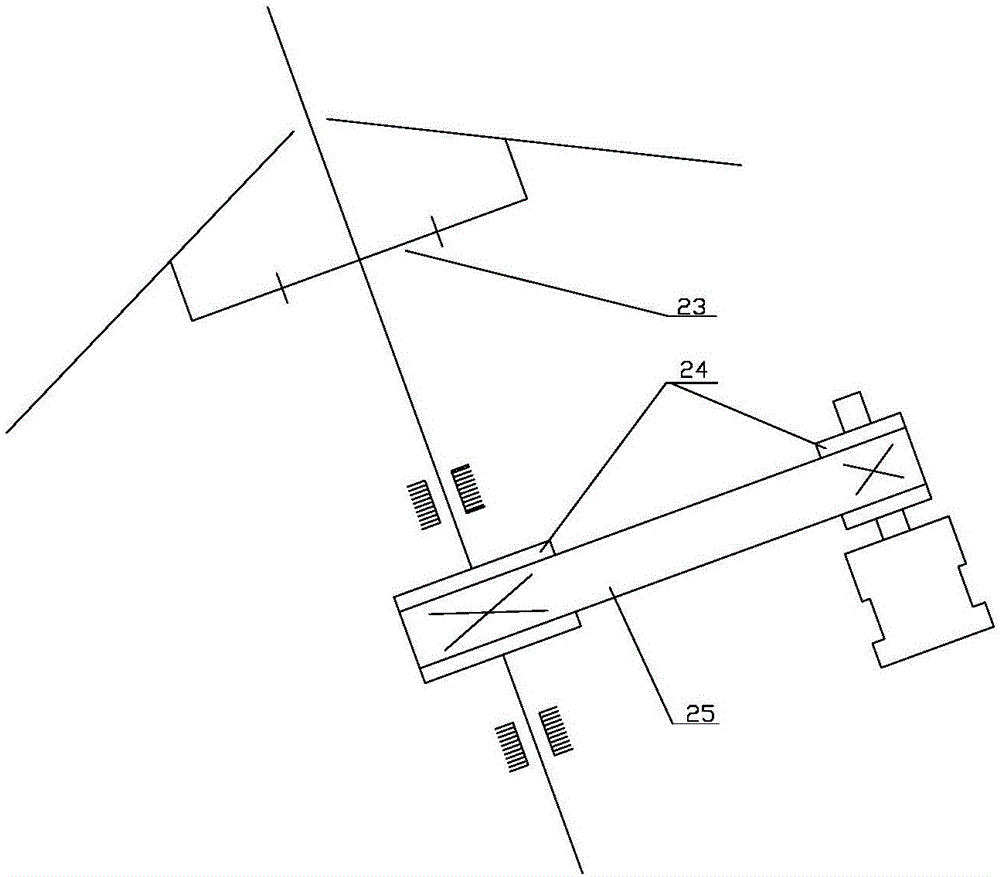

[0034] Such as figure 1 Shown, a kind of shoe-washing machine comprises a chassis, in which there are inclined turntables 10, disinfection lamps 6, dryers 7 and net pockets for collecting impurities, etc., and a machine cover and a control device are arranged outside the casing. Four fixtures 8 for placing shoes are evenly arranged on the turntable 10. The center of the turntable 10 is provided with a central nozzle 3 facing the upper edge of the turntable 10. The top of the chassis is located above the turntable 10. The top nozzle 4, the central nozzle 3 and the top nozzle 4 are all connected to the water inlet 5 through the water inlet pipe 9, and the water inlet pipe 9 is provided with a booster valve 15, and the air bubbles with the outlet facing the turntable 10 for bubble washing are also arranged in the cabinet. Generator 2, the bubble g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com