A Method for Lossless Droplet Transfer by Controlling the Temperature of a Superhydrophobic Metal Substrate

A metal substrate and substrate temperature technology, applied in chemical instruments and methods, chemical/physical processes, chemical/physical/physicochemical processes, etc., to achieve the effects of easy operation, high efficiency, and strong interchangeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

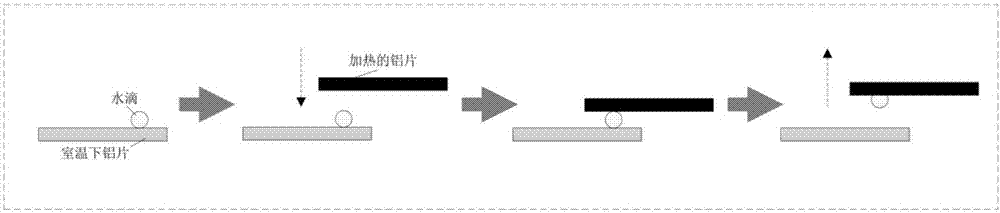

[0023] The superhydrophobic aluminum sheet a was placed horizontally, and a 10 μL droplet was placed on the surface of the superhydrophobic metal substrate a at room temperature, and the water droplet formed a spherical shape on the surface. Heat another superhydrophobic aluminum sheet b to 40°C, and keep its temperature higher than 30°C before the superhydrophobic aluminum sheet b touches the liquid droplets on the superhydrophobic aluminum sheet a, and slowly move the superhydrophobic aluminum sheet b from the vertical direction Move towards the droplet, lightly touch the droplet, and slowly lift the superhydrophobic aluminum sheet b, and the droplet adheres to the superhydrophobic aluminum sheet b at this time. At this time, the grasping action is completed, and the transfer of water droplets is realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com