Method and device for continuous severe plastic deformation in different compression-shear composite strain paths

A large plastic deformation and shear deformation technology, applied in the direction of metal extrusion dies, metal extrusion mandrels, etc., can solve the problems of complex mold processing, large extrusion force, and limited processing blank size, and achieve cumulative Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

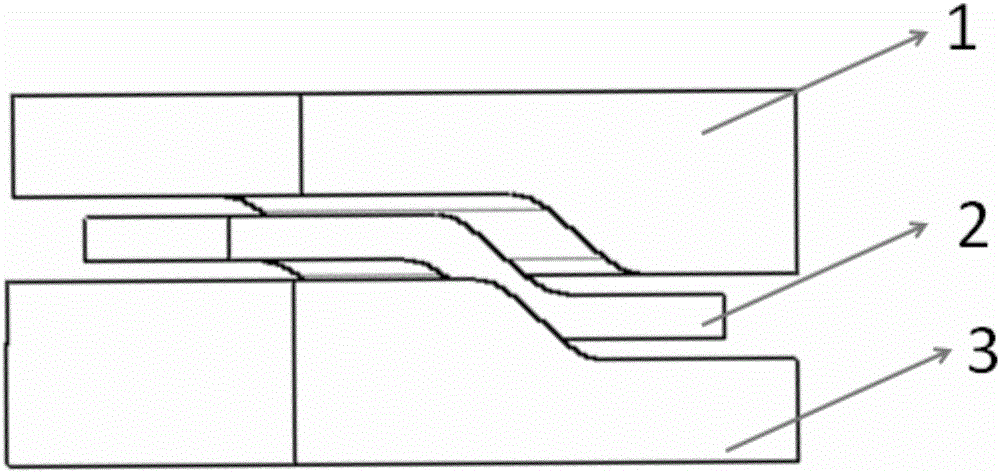

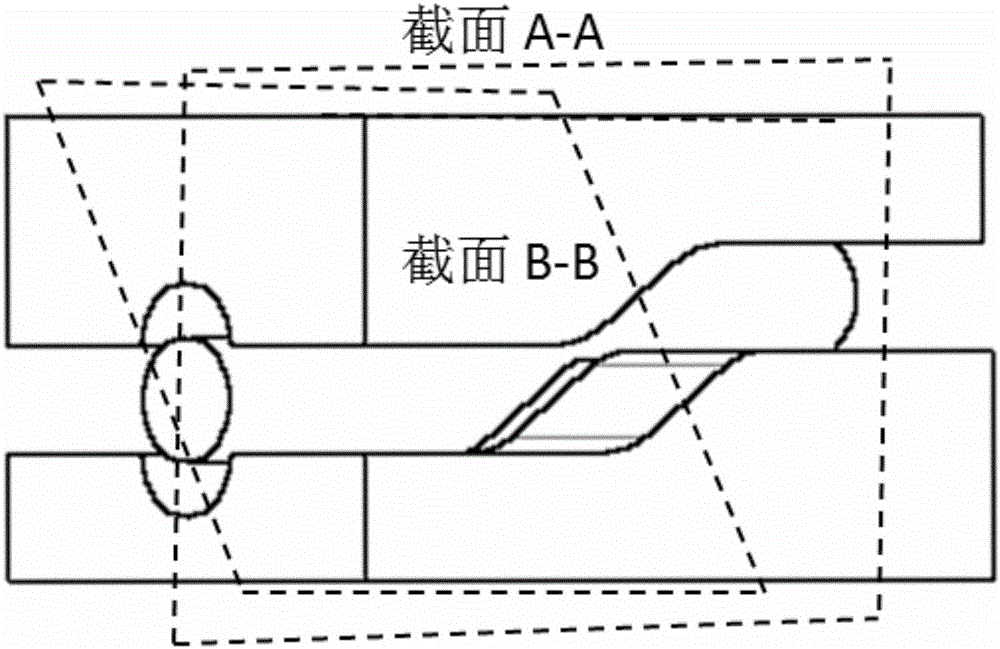

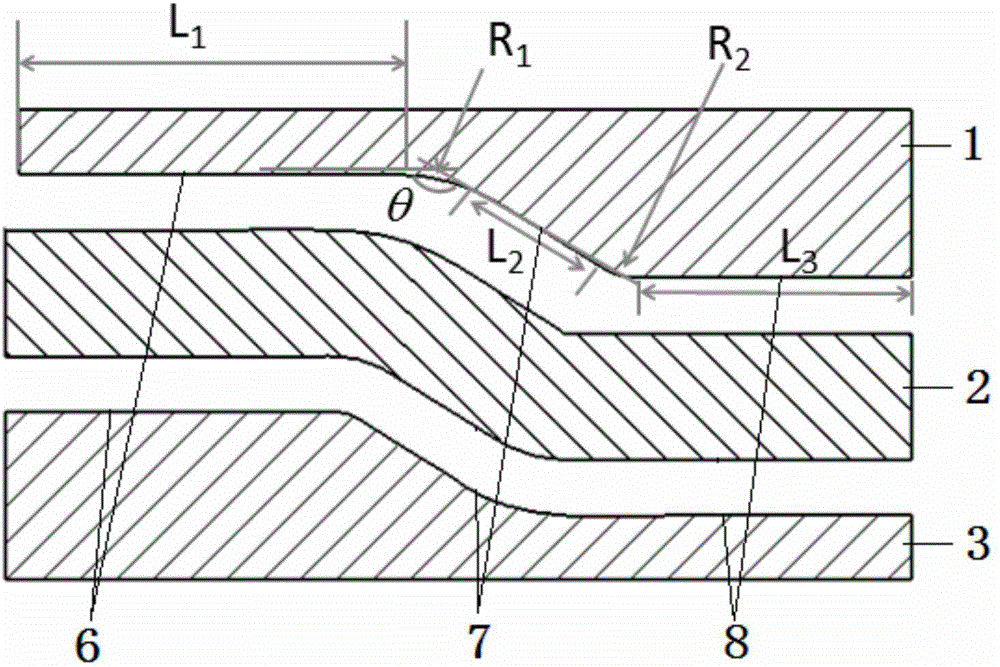

[0038]The invention is not only suitable for bar processing, but also can be used for plate processing. This embodiment takes plate processing, shearing and pressure deformation as an example to illustrate. For the mold equipment and plate forming results, see figure 1 , Figure 5 , Figure 6(a) and Figure 6(b). see figure 1 And Fig. 3 (a), this device is provided with upper mold 1, lower mold 3 and feeding mechanism, upper mold 1 is fixed with upper mold base, lower mold 3 is fixed with lower mold base, blank 2 is fixed with feeding mechanism, blank 2 It is located between the upper die 1 and the lower die 3; the corresponding surfaces of the upper die 1 and the lower die 3 and the blank 2 include: the upper flat section I6, the lower flat section II8, the curved section 7, and the upper flat section The transition between I6 and the flat section II8 at the lower part is connected by the curved section 7, the transition between the flat section I6 at the upper part and the ...

Embodiment 2

[0046] Such as figure 2 , Fig. 3 (a) and Fig. 3 (b), in the present embodiment 2, the bar compression-shear processing is also taken as an example to illustrate the basic process and principle of realizing the one-shear-two-compression stress state in the plate. The device is equipped with an upper mold 1, a lower mold 3 and a feeding mechanism. The upper mold 1 is fixed to the upper mold base, the lower mold 3 is fixed to the lower mold base, and the blank 2 is fixed to the feeding mechanism. The blank 2 is located between the upper mold 1 and the lower mold. Between 3; the corresponding surfaces of the upper die 1 and the lower die 3 and the blank 2 include: the upper flat section I6, the lower flat section II8, and the curved section 7, the upper flat section I6 and the lower flat section The transition between II8 is connected by the curved section 7, the rounded transition is adopted between the upper flat section I6 and the curved section 7, and the rounded transition i...

Embodiment 3

[0052] In this embodiment 3, the basic process and principle of realizing one-shear and three-compressive stress states are also described by taking plate compression-shear processing as an example, see Figure 4 . See Figure 3(a) and Figure 4 , the device is provided with an upper mold 1, a lower mold 3 and a feeding mechanism, the upper mold 1 is fixed to the upper mold base, the lower mold 3 is fixed to the lower mold base, the blank 2 is fixed to the feeding mechanism, and the blank 2 is located between the upper mold 1 and the lower mold base. Between the molds 3, the right side extrusion die 4 and the left side extrusion die 5 are arranged on both sides of the billet 2 respectively; the corresponding surfaces of the upper die 1 and the lower die 3 and the billet 2 respectively include: the flat section I6 located on the upper part, the The lower flat section II8 and curved section 7, the upper flat section I6 and the lower flat section II8 are connected and transitione...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com