Constant-temperature system for semi-solid press-injecting device

A constant temperature system, semi-solid technology, applied in the field of constant temperature system, can solve the problem of uneven temperature of semi-solid slurry, and achieve the effect of ensuring flow consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0020] The following will refer to the attached Figure 1-3 The invention will be described in detail in conjunction with the embodiments.

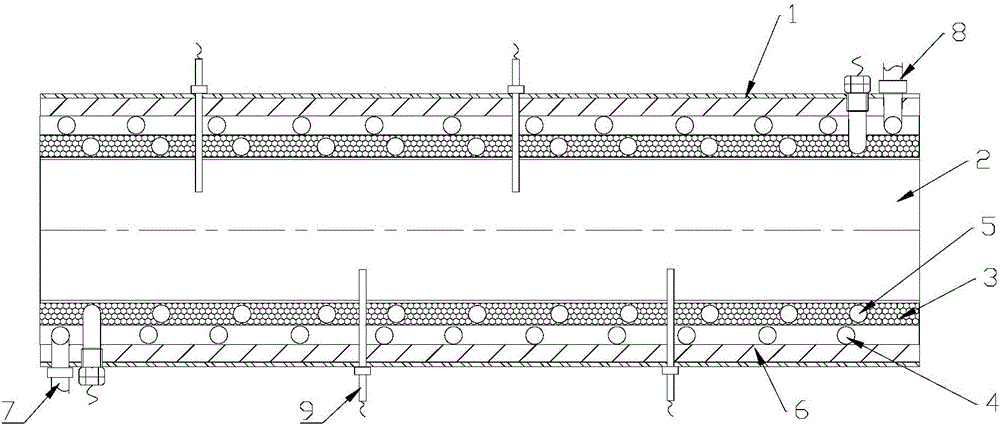

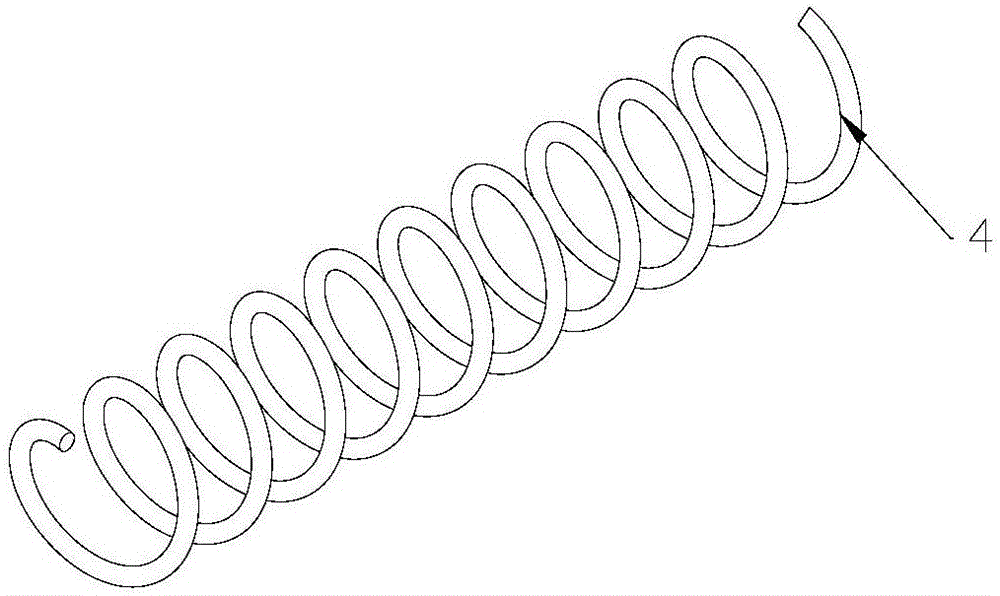

[0021] Such as figure 1 As shown, a constant temperature system for a semi-solid injection device includes a casing 1 and a barrel 2, the casing 1 is sleeved outside the barrel 2, and between the casing 1 and the barrel 2 A heat conduction layer 3 is provided, and a condensation water pipe 4 is provided on the outer surface of the heat conduction layer 3 .

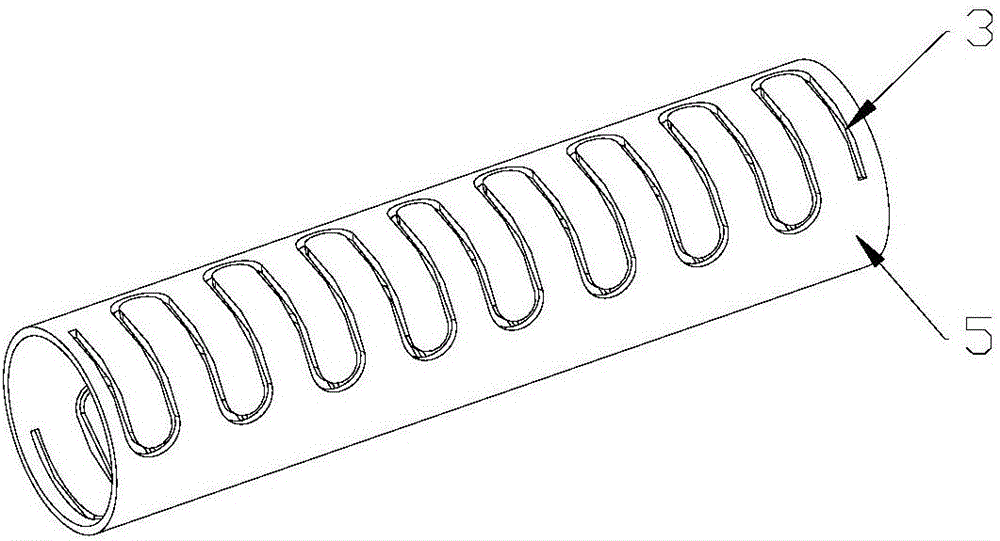

[0022] Such as Figure 1-3 As shown, the heat conduction layer 3 is made of a heat conduction material (such as high heat conduction carbon fiber, etc.), the heat conduction layer 3 is embedded with an inductance coil 5, and the inductance coil 5 is distributed along the axial direction of the heat conduction lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com