Robot for butting before welding of multiple vertical steel pipes

A technology of robots and steel pipes, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as low efficiency, cumbersome process, and difficulty in ensuring accuracy, so as to improve efficiency, ensure accuracy, and save manual docking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

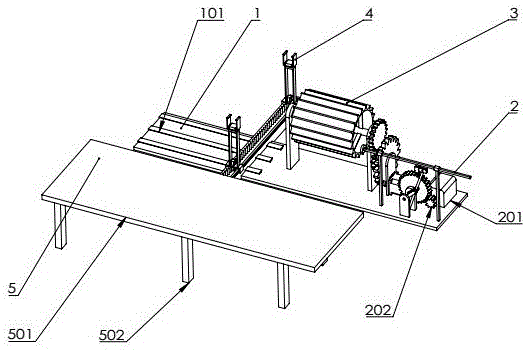

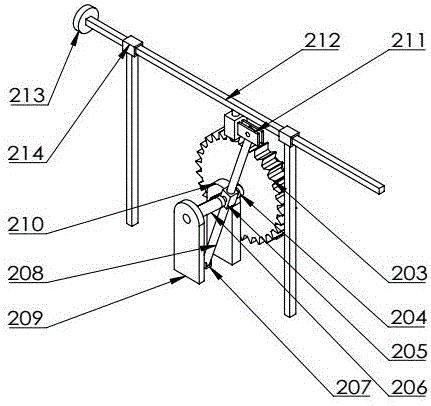

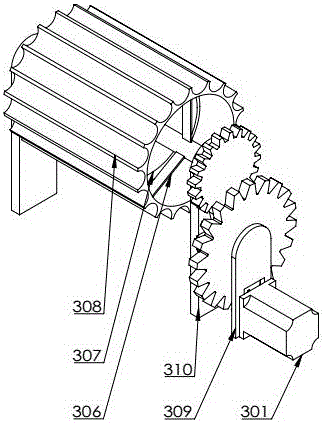

[0013] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a multi-vertical steel pipe welding pre-welding robot includes a machine base 1, a horizontal tube propulsion system 2, a feeding system 3, a vertical tube propulsion system 4, and a cooling platform 5. It is characterized in that: the horizontal tube propulsion system 2 includes DC motor 201, first gear 202, second gear 203, first shaft 204, first slide block 205, two cranks 206, articulated frame 207, rocking bar 208, crank support 209, first gear shaft support 210, the first Two sliders 211, a push rod 212, a contact head 213, and two push rod brackets 214, the DC motor 201 is fixedly mounted on the support 1, and the first gear 202 is fixedly mounted on the motor shaft of the DC motor 201, The second gear 203 is fixedly installed on the right end of the first shaft 204, and the left end is connected to the crank 206 through an elastic coupling, and the two cranks 206 are respectively rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com