Ultrahigh-layer special-shaped steel pipe column assembly method

A special-shaped steel pipe and assembly method technology, which is applied in the direction of assembly machines, workbenches, metal processing equipment, etc., can solve the problems of low precision and large processing errors of super high-rise special-shaped steel pipe columns, and achieve the effect of reducing errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

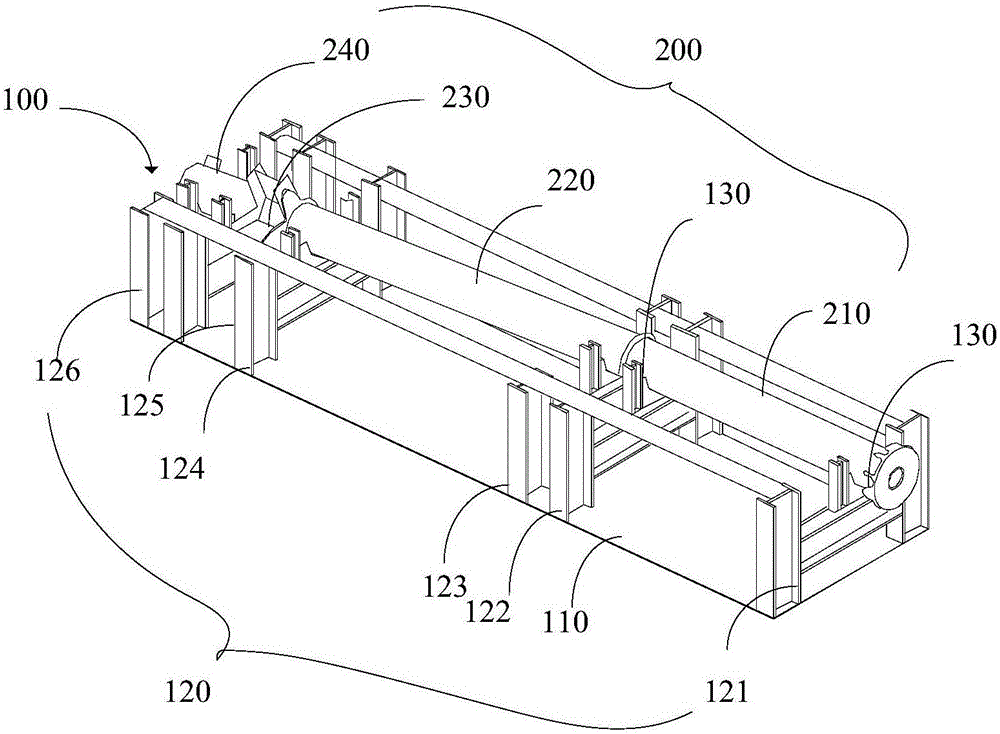

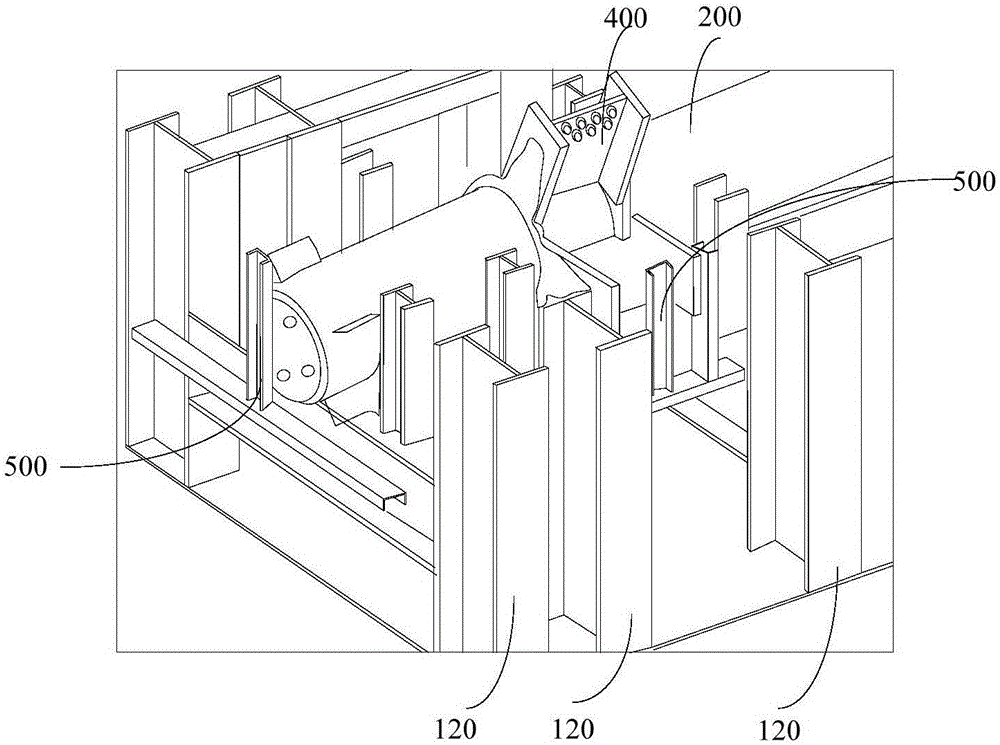

[0053] This embodiment provides a method for assembling a super-high-rise special-shaped steel pipe column, such as figure 1 , 3 shown, including the following steps:

[0054] S101, performing a three-dimensional modeling design on the tire frame 100 according to the size of the super-high-rise special-shaped steel pipe column 200;

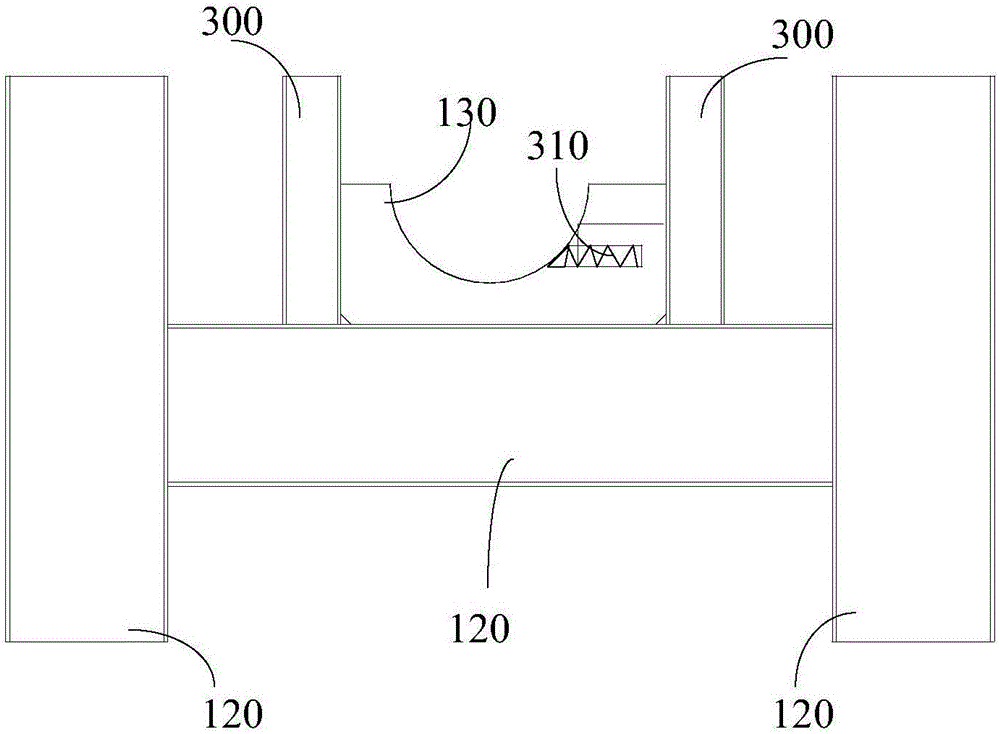

[0055]S102, prepare the tire frame 100, wherein the tire frame 100 includes a horizontal base 110, a fixed bracket 120 and a positioning plate 130, the fixed bracket 120 is located above the horizontal base 110; the side of the fixed bracket 120 away from the horizontal base 110 forms a limit groove; the inner side wall of the limit groove is provided with a positioning plate 130 to adjust the angle and orientation of the super-high-rise special-shaped steel pipe column 200;

[0056] S103 , assembling the super high-rise special-shaped steel pipe column 200 on the tire frame 100 .

[0057] The method for assembling a super-high-rise special-sha...

Embodiment 2

[0076] This embodiment provides a method for assembling super high-rise special-shaped steel pipe columns on the basis of the above-mentioned embodiments. During the assembly process of the above-mentioned super high-rise special-shaped steel pipe columns, there are also steps of detection and adjustment, as follows:

[0077] S201, in the tire frame preparation process, after the preparation of the horizontal base 110, the fixing bracket 120 and the positioning plate 130 needs to be tested, if the horizontal base 110, the fixing bracket 120 and the positioning plate 130 meet the design requirements, the horizontal base 110, fixed The bracket 120 and the positioning plate 130 are assembled.

[0078] The above-mentioned inspection process can screen out the parts that do not meet the standards, so as to ensure that the preparation of the tire frame meets the design requirements.

[0079] S202, during the preparation process of the tire frame 100, after the assembly of the horizo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com