Full-automatic utility knife assembling apparatus

An assembly equipment and fully automatic technology, which is applied in metal processing equipment, assembly machines, metal processing, etc., can solve the problems of low automation, high labor cost, and low work efficiency, and achieve the effect of high automation and novel structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The present invention will be described below in conjunction with specific embodiments.

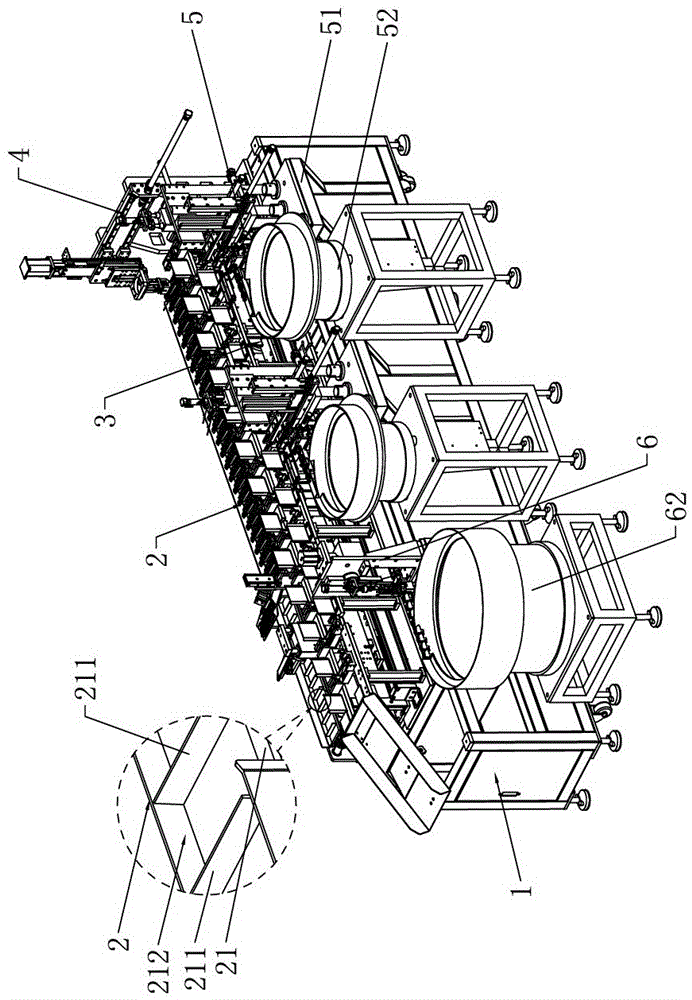

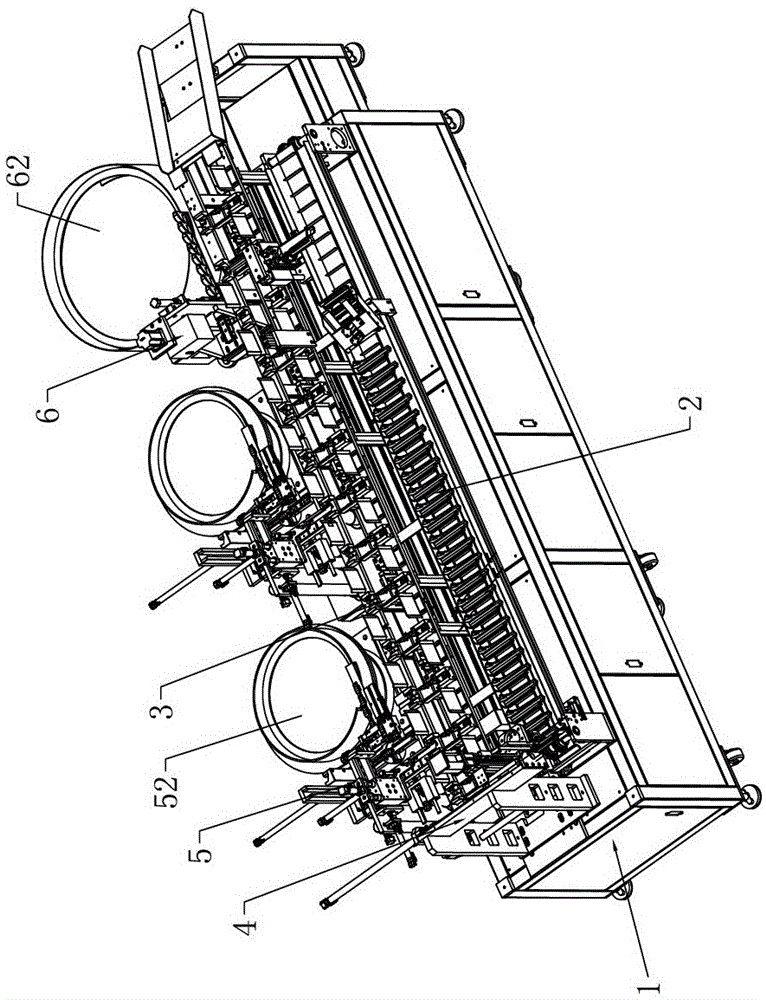

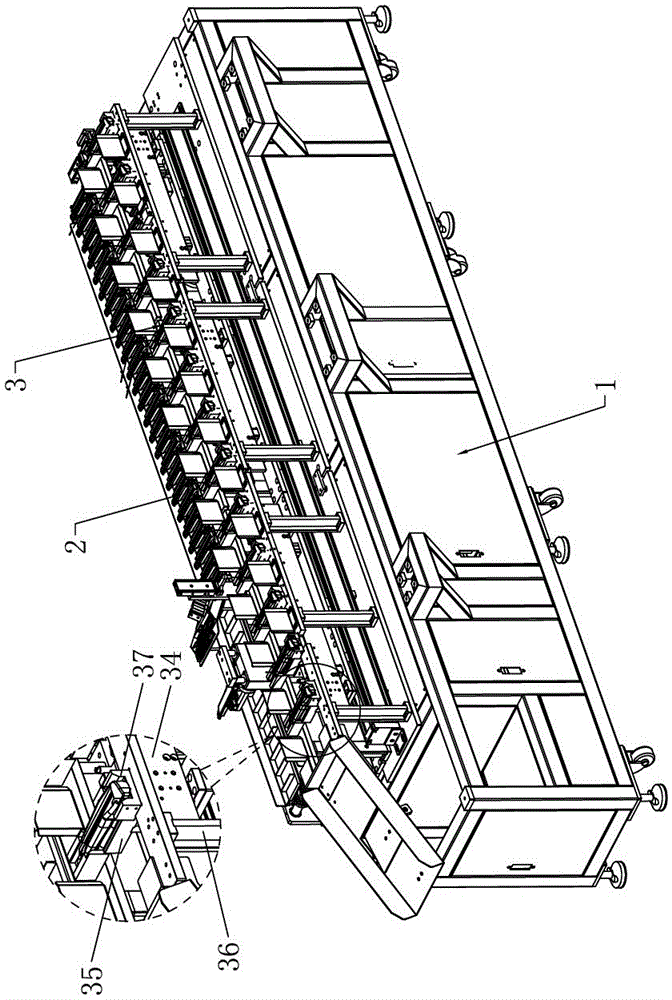

[0064] Such as Figure 1 to Figure 5 As shown, a utility knife automatic assembly equipment includes a frame 1, the upper end of the frame 1 is equipped with a feeding conveyor belt 2 horizontally arranged along the left and right directions, an assembly transfer assembly 3, and an assembly transfer assembly 3 Located at the rear end side of the feeding conveyor belt 2, the conveyor belt 21 of the feeding conveyor belt 2 is provided with belt partitions 211 evenly spaced along the conveyor belt 21, and a knife is formed between two adjacent belt partitions 211. The shell placement slot 212, the assembly transfer assembly 3 includes a transfer drive linear module 31 screwed on the frame 1 and extending horizontally along the left and right directions, the upper end of the transfer drive linear module 31 is equipped with a transfer drive linear module The driving end of 31 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com