Transfer-printing thermal-insulation antibacterial fabric

A fabric and lining fabric technology, applied in the field of fabrics and textile fabrics, can solve the problems of lack of thermal performance and antibacterial function, can not meet the needs of people, single function and other problems, to achieve good thermal performance, soft texture, good flexibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

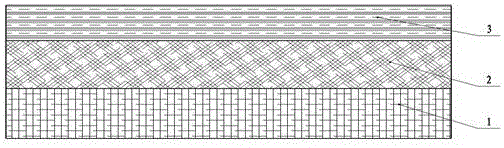

[0019] see figure 1 , the present invention relates to a kind of heat-preserving and bacteriostatic transfer fabric, comprising an inner layer, an insulating layer, and an outer layer. agents are fixed together.

[0020] Preferably, the inner layer is composed of the following raw materials by weight percentage: 45-60 wt% of cotton fiber and 40-50 wt% of bamboo fiber.

[0021] Preferably, the insulation layer is composed of the following raw materials by weight percentage: 55-60 wt% of cotton fiber and 35-50 wt% of milk protein fiber.

[0022] Preferably, the outer layer is composed of the following raw materials by weight percentage: 40-50 wt% of wool fiber, 15-30 wt% of viscose fiber, and 15-30 wt% of polyester fiber.

[0023] Preferably, the cotton fiber is long-staple cotton with a linear density of 1.43dtex.

[0024] Preferably, the fineness of the bamboo fiber is 2.58dtex.

[0025] Preferably, the adhesive is a water-based polyurethane adhesive.

[0026] The back si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com