Full-automatic culture medium filling machine

A filling machine, culture medium technology, applied in packaging, mixer, transportation and packaging, etc., can solve the problems of accelerated aging, improper operation, easy to hurt people, etc., and achieve the effect of high thermal efficiency, beautiful design and stable work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

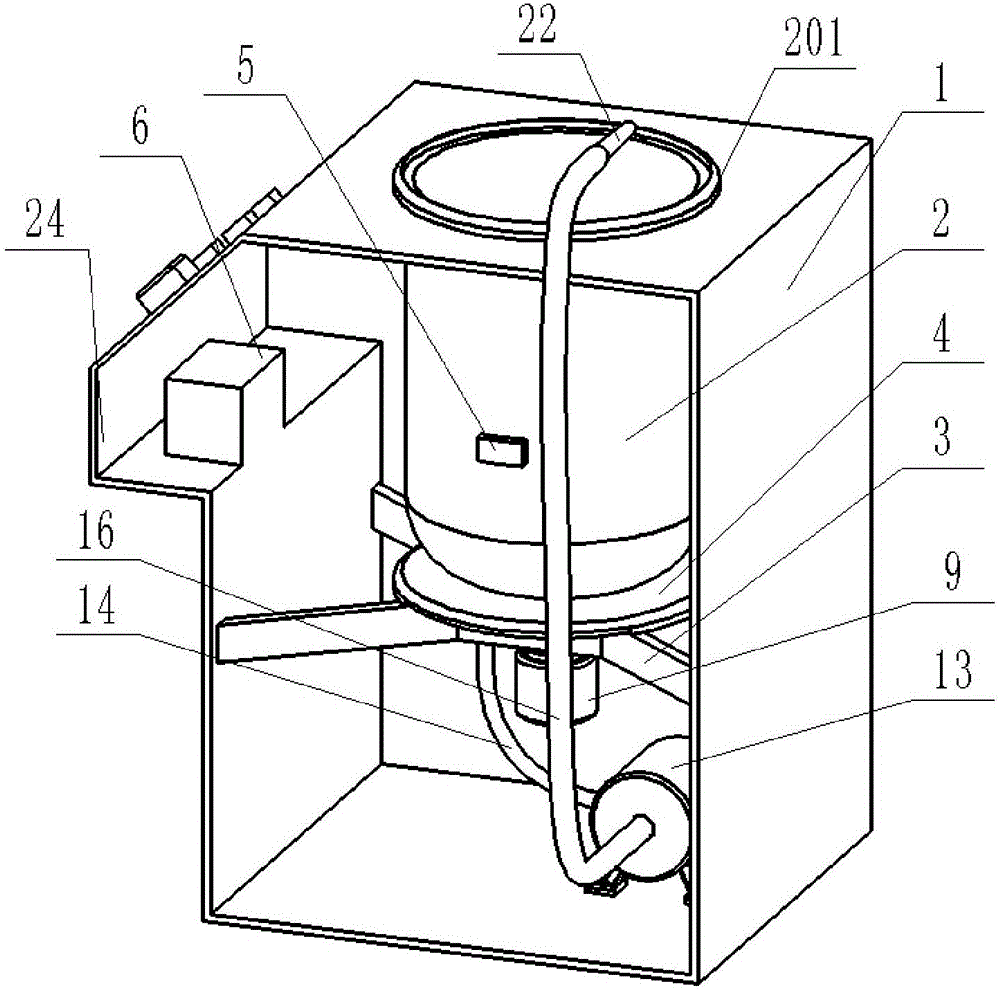

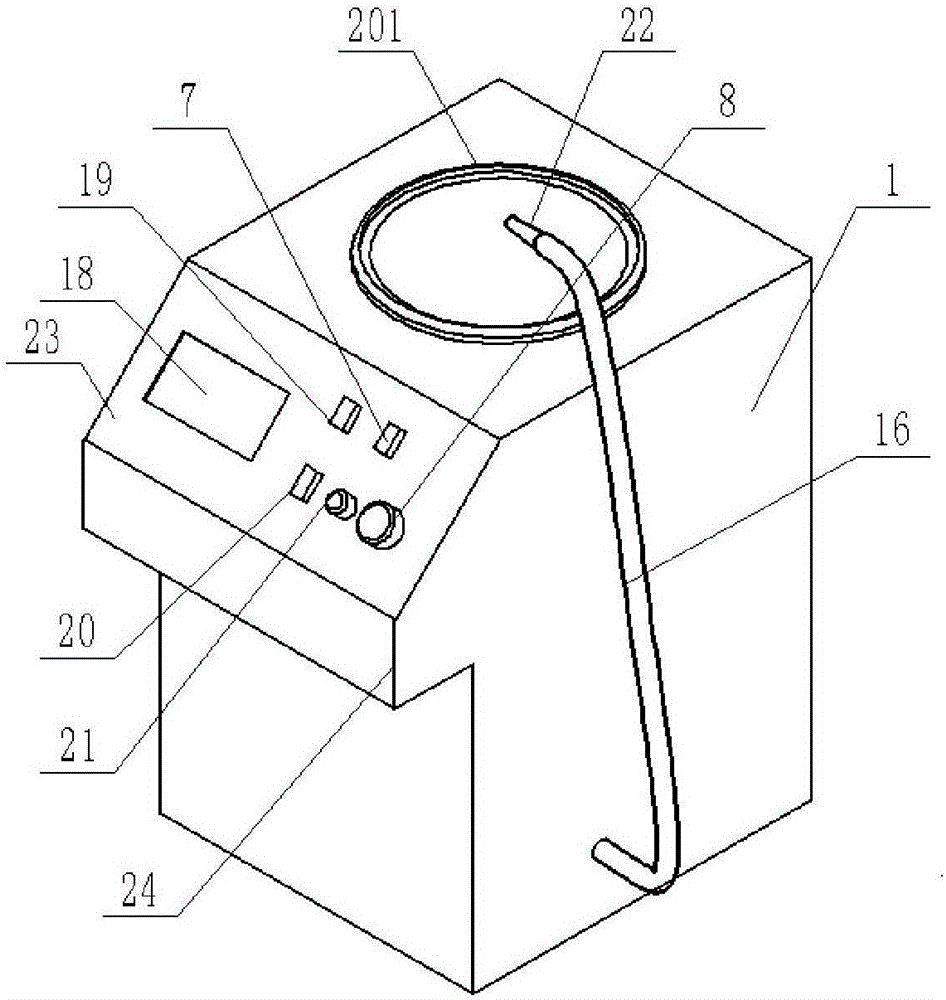

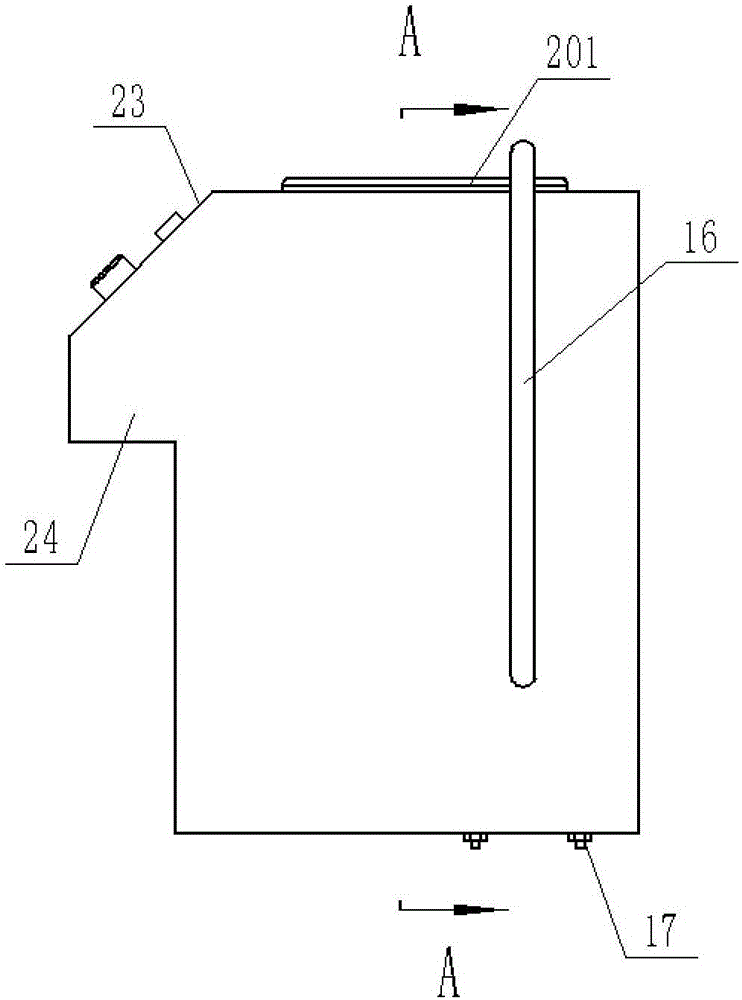

[0027] according to Figure 1 to Figure 6 As shown, a fully automatic culture medium filling machine includes a filling machine housing 1, a liquid storage tank 2 and a hydraulic pump 13, and the liquid storage tank 2 is located at the upper end of the inner cavity of the filling machine housing 1, so The middle position of the upper end surface of the filling machine housing 1 is provided with a hole corresponding to the outer cylindrical surface of the liquid storage tank 2, and the outer cylindrical surface of the liquid storage tank 2 is connected to the inner cylindrical surface of the hole at the middle position of the upper end surface of the filling machine housing 1. Cooperate with the contact, the hole in the middle of the upper end surface of the filling machine housing 1 plays a radial positioning role for the liquid storage barrel 2, and the upper end of the liquid storage barrel 2 is provided with a circular protrusion 201 with a fan-shaped cross section, The pla...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap