Robot for cargo handling in logistics warehouse

A cargo loading and unloading, robot technology, applied in the field of robots for cargo loading and unloading in logistics warehouses, can solve problems such as cargo falling, safety accidents, cargo swing, etc., to avoid displacement, improve safety and reliability, and achieve the effect of small force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

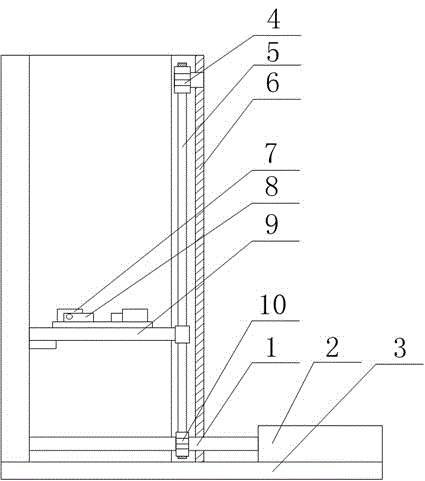

[0018] Such as figure 1 As shown, the present embodiment includes a support plate 13, a motor 12 and two columns 6 are arranged on the support plate 13, a rectangular groove is opened on the side walls opposite to each other of the two columns 6, and a connecting rod 11 is connected to the output end of the motor 12. , the connecting rod 11 runs through the side wall of any one of the two columns 6 and is placed in a rectangular groove, an upper gear 4 is installed on the upper end of the rectangular groove, and two lower gears 10 are installed on the end of the connecting rod 11, said The upper gear 4 is connected with the lower gear 10 through the toothed belt 5. A ferrule is fixed on the inner wall of the toothed belt 5. The end of the lifting plate 9 is fixed in the ferrule. There are two reverse mountings on the upper wall of the lifting plate 9. Cylinder 7, the direction of motion of the output end of the cylinder 7 is the same as the direction in which the goods move ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com