Antiskid folding type ground lifting machine suitable for car maintaining

A non-slip folding, automobile maintenance technology, applied in the direction of lifting frame, lifting device, etc., can solve the problems of asynchronous lifting structure, working platform not rising horizontally, smashing staff, etc., to avoid scratches or pits, avoid The effect of reducing stability and enhancing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

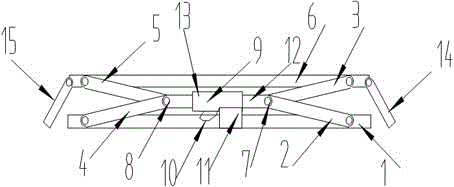

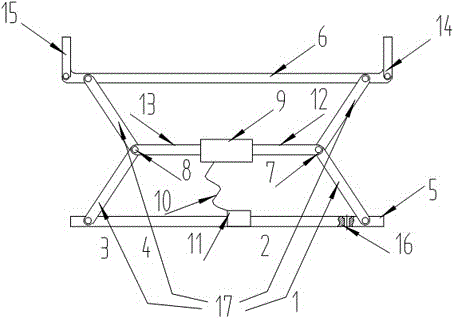

[0025] The present invention is an anti-skid folding ground lifter suitable for automobile maintenance, which includes a base 5 and a working platform 6 directly above the base 5, and also includes a right baffle 14 and a left baffle 15 respectively arranged at both ends of the working platform 6 , and the folding rod group 17, the double-acting hydraulic cylinder 9 and the oil pressure pipe 10 arranged between the base 5 and the working platform 6, and one end of the oil pressure pipe 10 is connected with the double-acting hydraulic cylinder 9. The folding lever group 17 includes a first push rod 1 , a second push rod 2 , a third push rod 3 , a fourth push rod 4 , a right hinge shaft 7 , and a left hinge shaft 8 . Among them: one end of the first push rod 1 and one end of the third push rod 3 are respectively hinged with the base 5; one end of the second push rod 2 and one end of the fourth push rod 4 are respectively hinged with the working platform 6; the right piston of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com