Prefabricated reinforced concrete component connecting method

A technology of reinforced concrete and precast concrete, which is applied in the direction of building structure and construction, can solve the problems of difficult to guarantee construction quality, difficult to guarantee grouting quality, and complicated construction process, so as to improve the connection performance of steel bars, improve the bonding performance, and facilitate construction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The method for connecting prefabricated reinforced concrete members of the present invention will be described in detail below with reference to the accompanying drawings and embodiments.

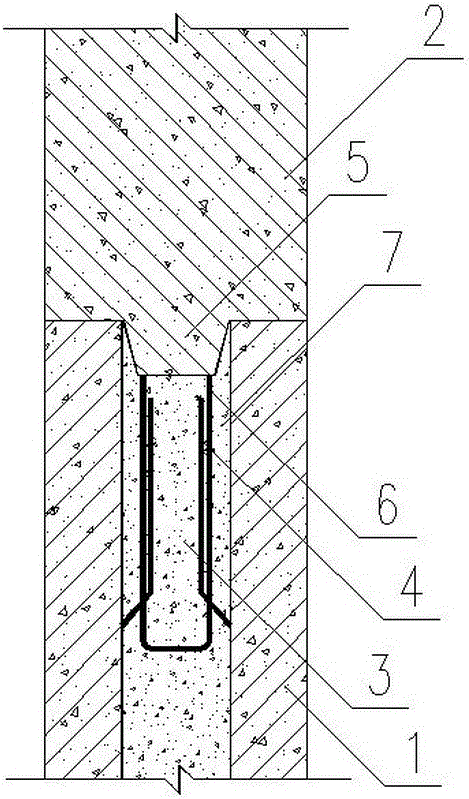

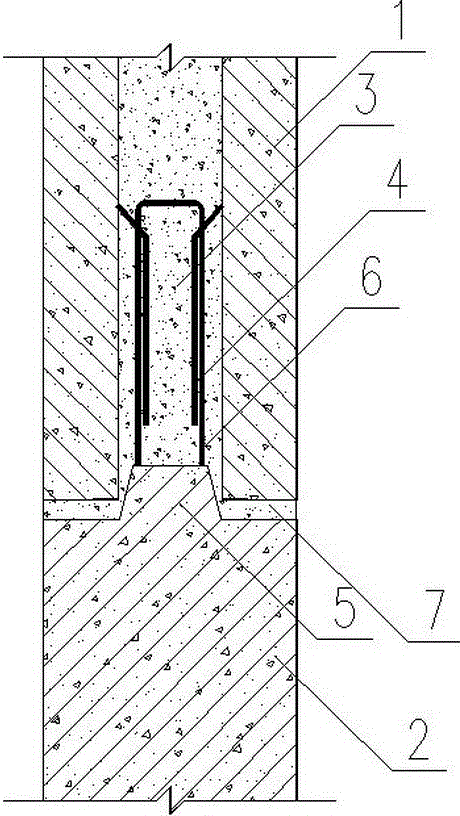

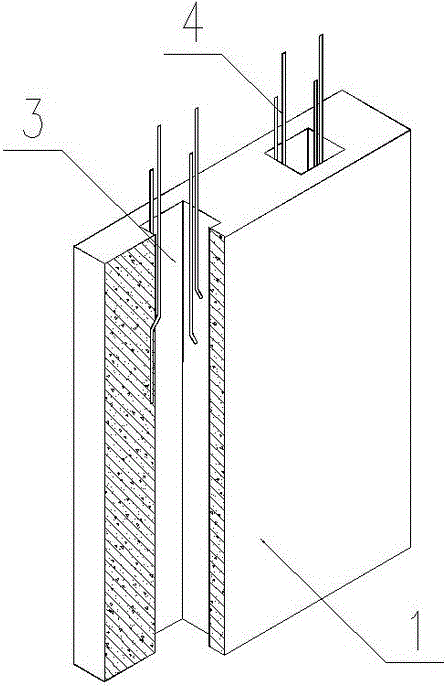

[0032] An embodiment of the method for connecting prefabricated reinforced concrete members proposed by the present invention, such as figure 1 or figure 2 or image 3 , the first prefabricated reinforced concrete component 1 is provided with at least one through hole 3 , a steel bar 4 is arranged in the hole 3 , and the steel bar 4 is anchored in the concrete on the side wall of the hole 3 . Concrete protrusions 5 are set on the second prefabricated reinforced concrete member 2, and anchoring steel bars 6 protrude from the protrusions 5; the first prefabricated reinforced concrete member 1 and the second prefabricated reinforced concrete member 2 are installed, and the second prefabricated reinforced concrete member 2 The protrusion 5 extends into the hole 3, and the anchoring st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com