An intelligent gunite wall plastering machine and its application

A painting machine and spraying technology, which is applied in the direction of construction and building construction, can solve the problems of inconvenient manual painting construction, time-consuming and labor-intensive manual painting, harsh construction environment, etc., achieve good economic benefits and market value, and save labor costs , Improve the effect of painting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

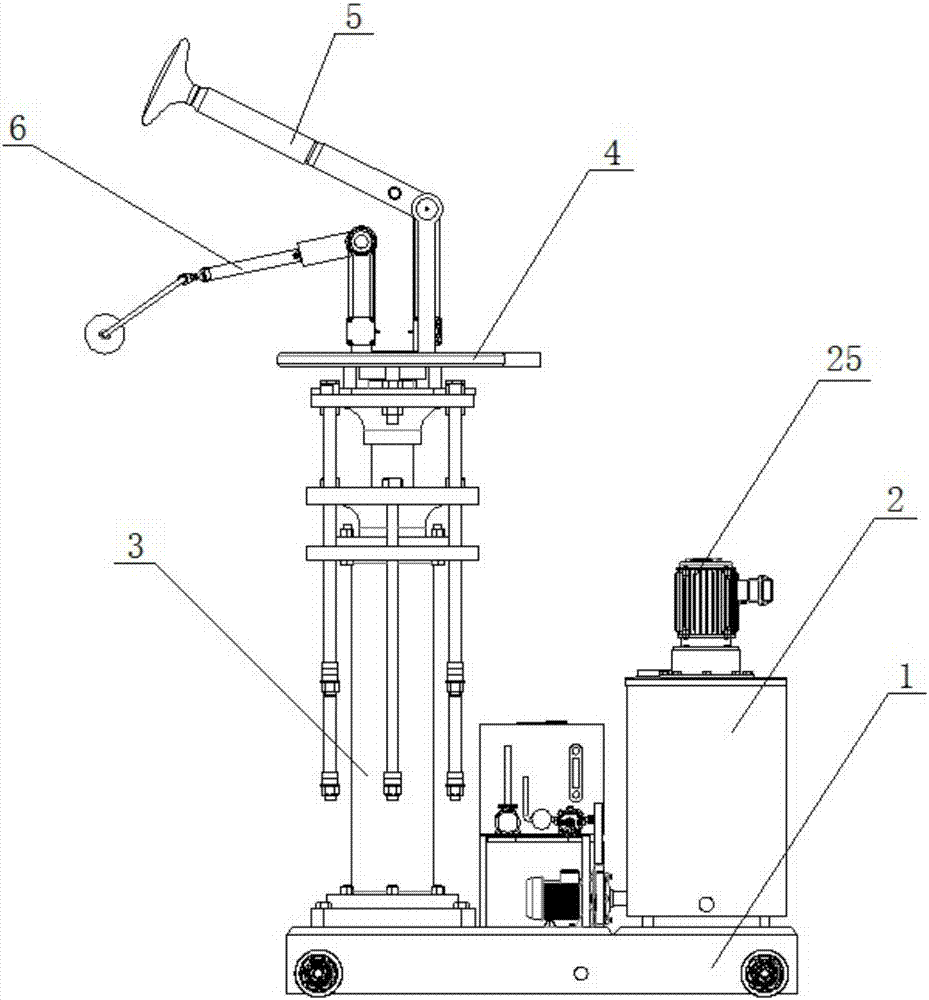

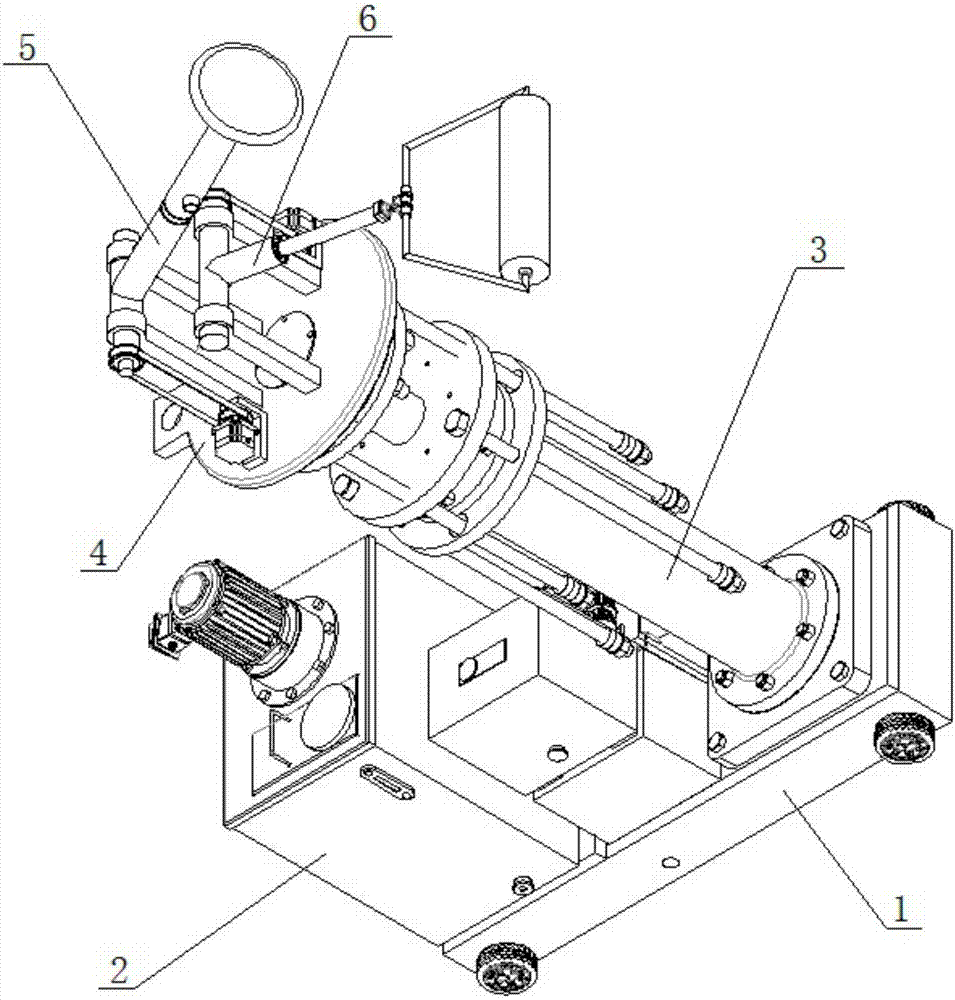

[0052] like Figure 1 to Figure 11 As shown, this embodiment provides an intelligent spraying wall painting machine, including a traveling mechanism 1, a slurry storage mechanism 2, a lifting mechanism 3, a rotating mechanism 4, a spraying mechanism 5 and a painting mechanism 6, a slurry storage mechanism 2, a lifting mechanism 3 is fixedly installed on the walking mechanism 1, the rotating mechanism 4 is installed on the top of the lifting mechanism 3, and the spraying mechanism 5 and the painting mechanism 6 are installed on the rotating mechanism 4;

[0053] Wherein, the walking mechanism 1 is used to drive the whole painting machine to move, including forward, backward, stop and turning;

[0054] The slurry storage mechanism 2 is used to store the slurry used by the spraying slurry mechanism 5, and the slurry to be sprayed has a good proportion in advance and is loaded into the slurry storage mechanism;

[0055] The lifting mechanism 3 realizes lifting up and down, and is...

Embodiment 2

[0069] A method for using the intelligent gunite wall painting machine described in embodiment 1 to paint walls up and down, comprising the following steps,

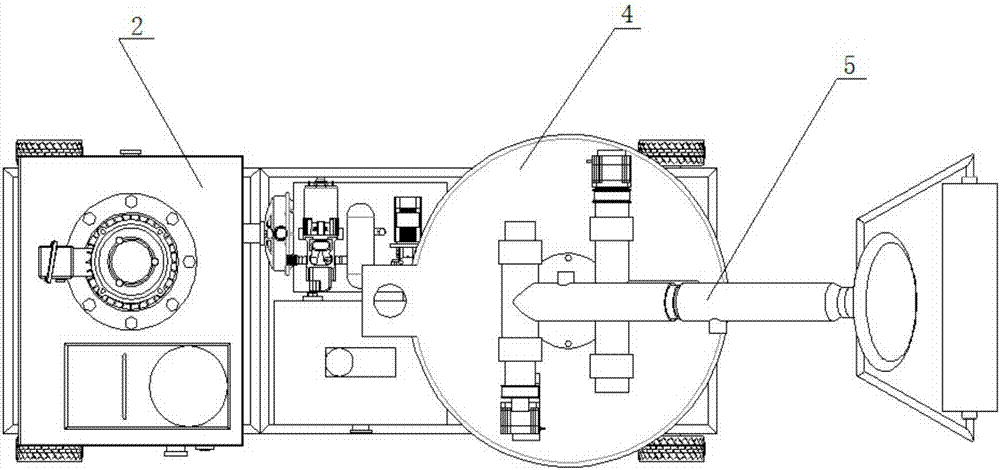

[0070] First, input the setting parameters through the electrical control cabinet, start the stirring motor 25, drive the stirring paddle to stir the slurry evenly, then start running according to the parameters set in advance, the secondary hydraulic telescopic cylinder starts to work, and the secondary hydraulic telescopic cylinder reaches After the designated position, the telescopic rod 12 stretches out to make the roller brush 14 stick to the wall, and at the same time the air pump 20 and the slurry pump 19 start to work, mix the gas and slurry into the spraying mechanism and spray it on the wall through the nozzle 11, and the painting mechanism The second motor 15 works, makes the rolling brush 14 stick to the wall and rolls up and down, and realizes the wall brushing operation.

Embodiment 3

[0072] A method of using the intelligent gunite wall painting machine described in Embodiment 1 to paint the walls left and right, the basic steps are as described in Embodiment 2, and the difference is that:

[0073] When it is necessary to brush the wall horizontally, the micro motor 13 at the front end of the telescopic rod 12 rotates to drive the roller brush 14 to realize a 90-degree rotation, and then the rotary stepping motor 23 is started to rotate the turntable 8, driving the roller brush 14 and the nozzle 11 to move horizontally, So as to realize the horizontal brushing of the wall.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com