A Method for Determining the Morphology of Caving Body in Segmented Pillarless Caving Method

A sub-caving method and caving body technology, which is applied in earth-moving drilling, surface mining, underground mining, etc., can solve the problems of large loss and dilution, difficult to observe the shape, and no method to determine the shape, so as to achieve full recovery of resources, The effect of reducing ore loss and dilution rate and optimizing structural parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

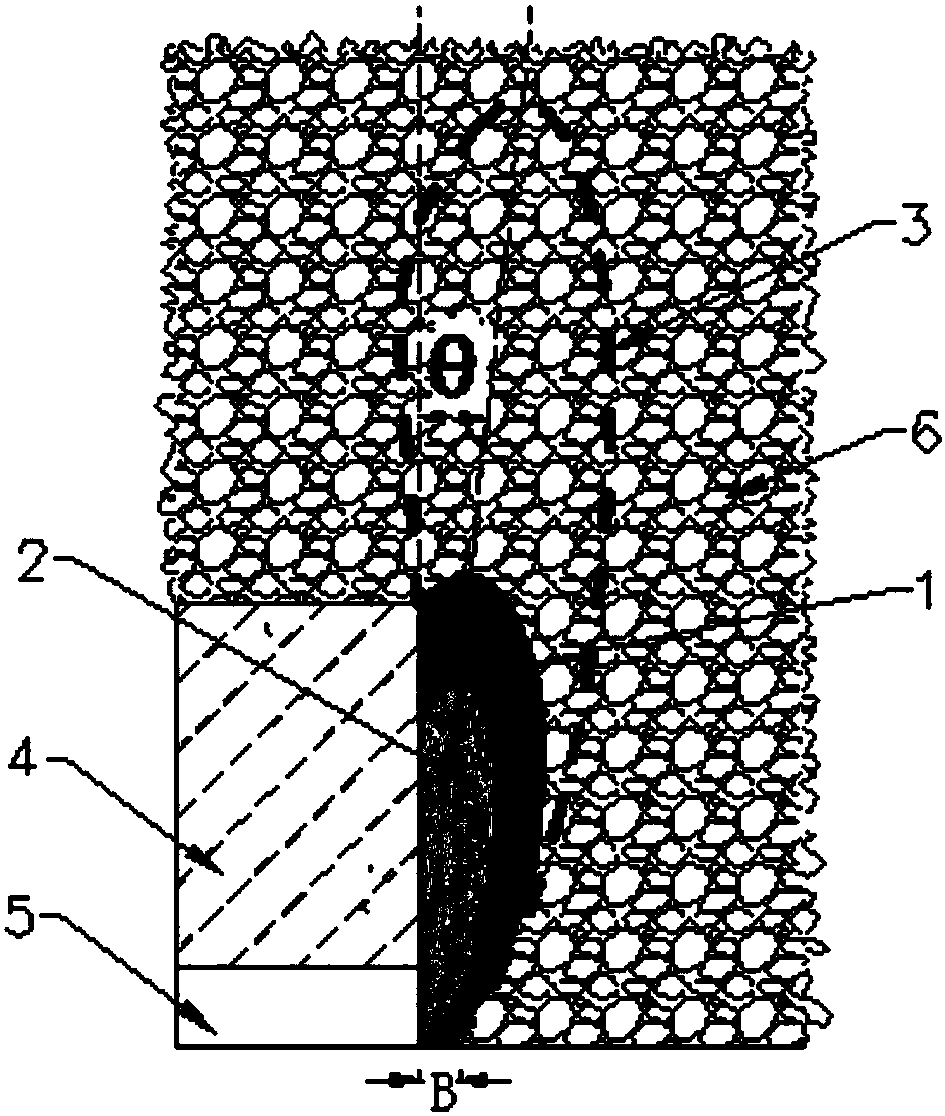

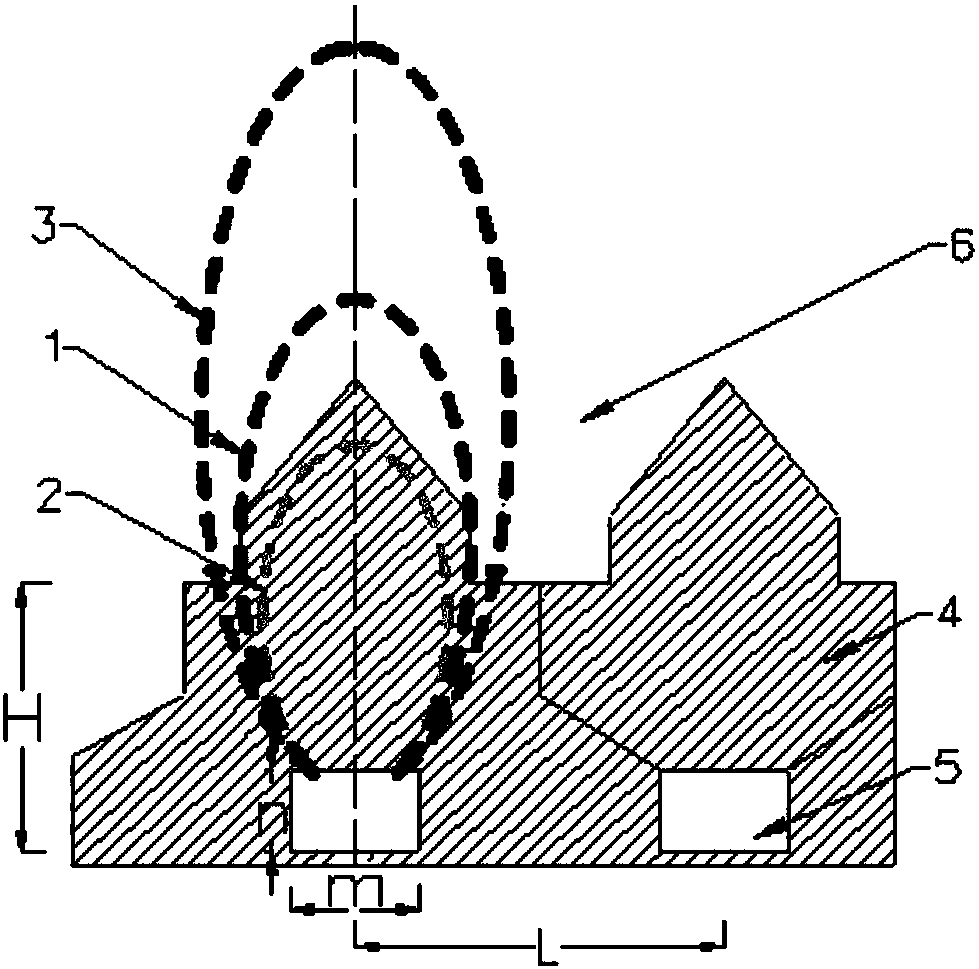

[0052] like figure 1 As shown, it is a relational diagram among the releasing body, the collapsing body and the loose body of the present invention. like figure 2 Shown is a schematic diagram of the sub-column mining face without pillars in the present invention. A method for determining the shape of the caving body in the segmental caving method without bottom pillars described in the present invention is based on the fact that the emanating body 2, the caving body 1 and the loose body 3 are similar ellipsoids, and the eccentricity of the three is the same. The volume of body 1 and the triaxial length of body 1 are used to determine the height and vertical approach of body 1 (i.e. figure 1 The width of the middle recovery approach 5) direction and the thickness along the approach direction; the concrete steps are as follows:

[0053] The fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com