Upward mining preparation and downward drift stoping with backfilling method

A technology of approach filling and mining method, applied in underground mining, filling, surface mining, etc., can solve the problems of ore body not having mining value, not adapting to production needs, difficult mining of ore body, etc., to ensure safe production operations , the effect of reducing the amount of development and mining projects, and increasing the profit of the mine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

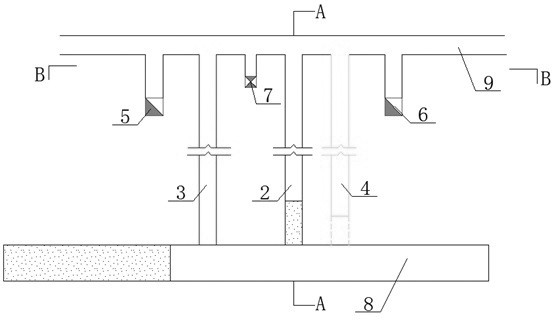

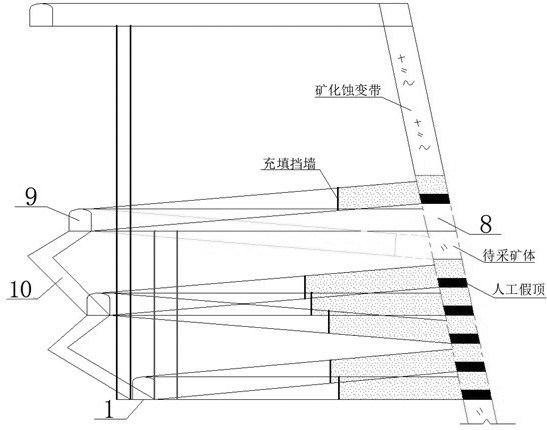

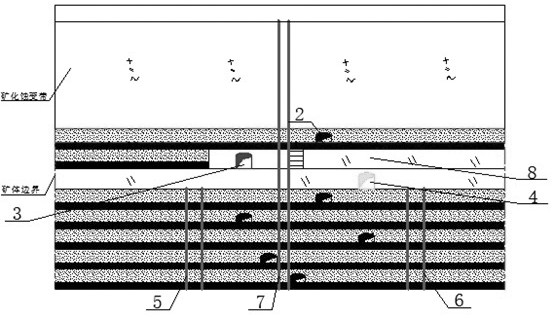

[0023] The specific implementation manners of the present application will be further described below in conjunction with the accompanying drawings.

[0024] Such as Figure 1-3 As shown, the upward mining and downward approach filling mining method involved in this application includes the following steps:

[0025] Step 1. Divide the stope into several segmented stopes from bottom to top, record the lowermost segmented stope as a segmented stope, and divide each segmented stope into several layered stopes from top to bottom 8. In this embodiment, assuming that the height of the middle section of the stope is 50m, the stope is first divided into several section stopes with a section height of 10.5m, and then each section stope is divided into several layers Stope 8, its stratification height is 3.5m.

[0026] Step 2. Arrange a filled return air pedestrian patio 7 in the stope, and use it as the second safety exit.

[0027] Step 3, excavation project: each section stope is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com