A mining-filling combined with continuous mining mining method in stage mines

A mining method and stage technology, applied in surface mining, mining equipment, underground mining, etc., can solve the problems of safety production threat, low production capacity, high labor intensity, reduce loss and dilution rate, improve production capacity, and achieve continuous sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, and the embodiments in the embodiments will be described by taking mining in a mining area divided into three mining stages as an example.

[0017] A stage mine mining method combining mining and filling with continuous mining, the steps are as follows:

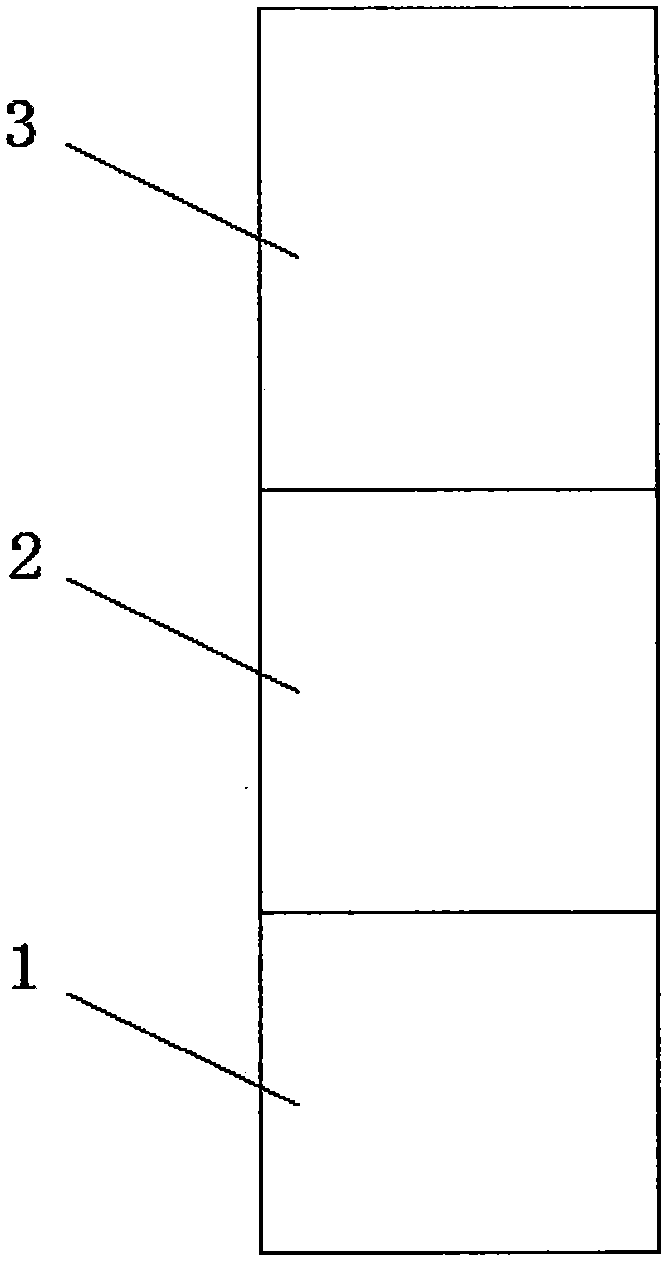

[0018] (I) if figure 1 As shown, according to the actual situation of the area to be mined, the area to be mined is divided into several mining stages from bottom to top;

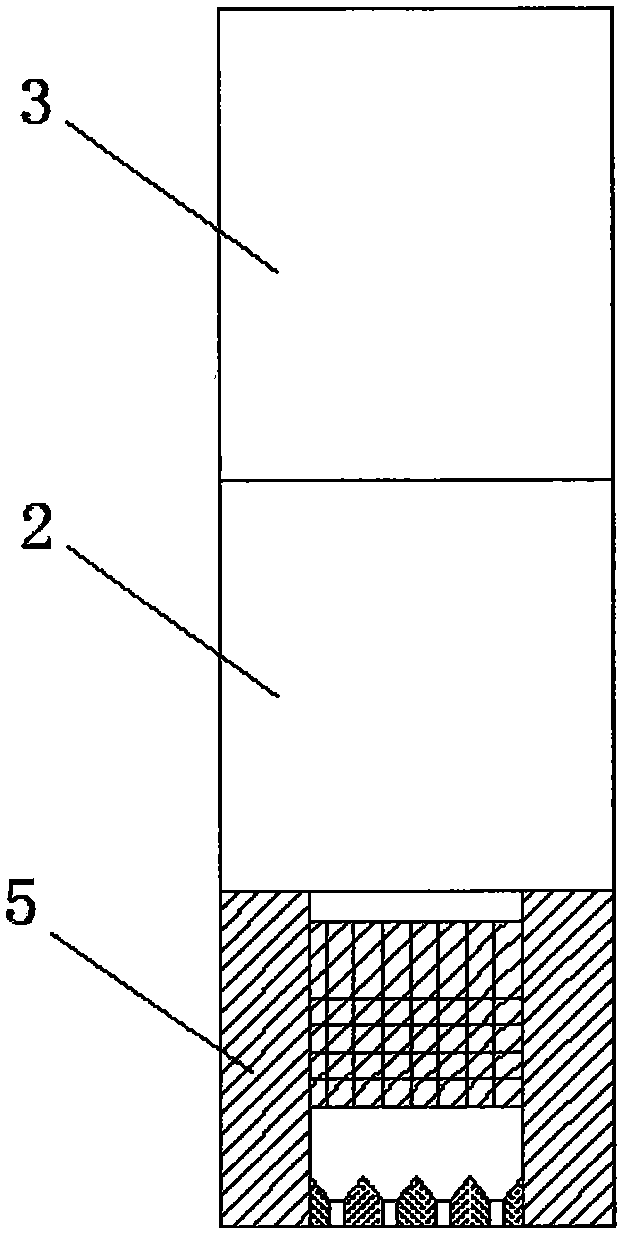

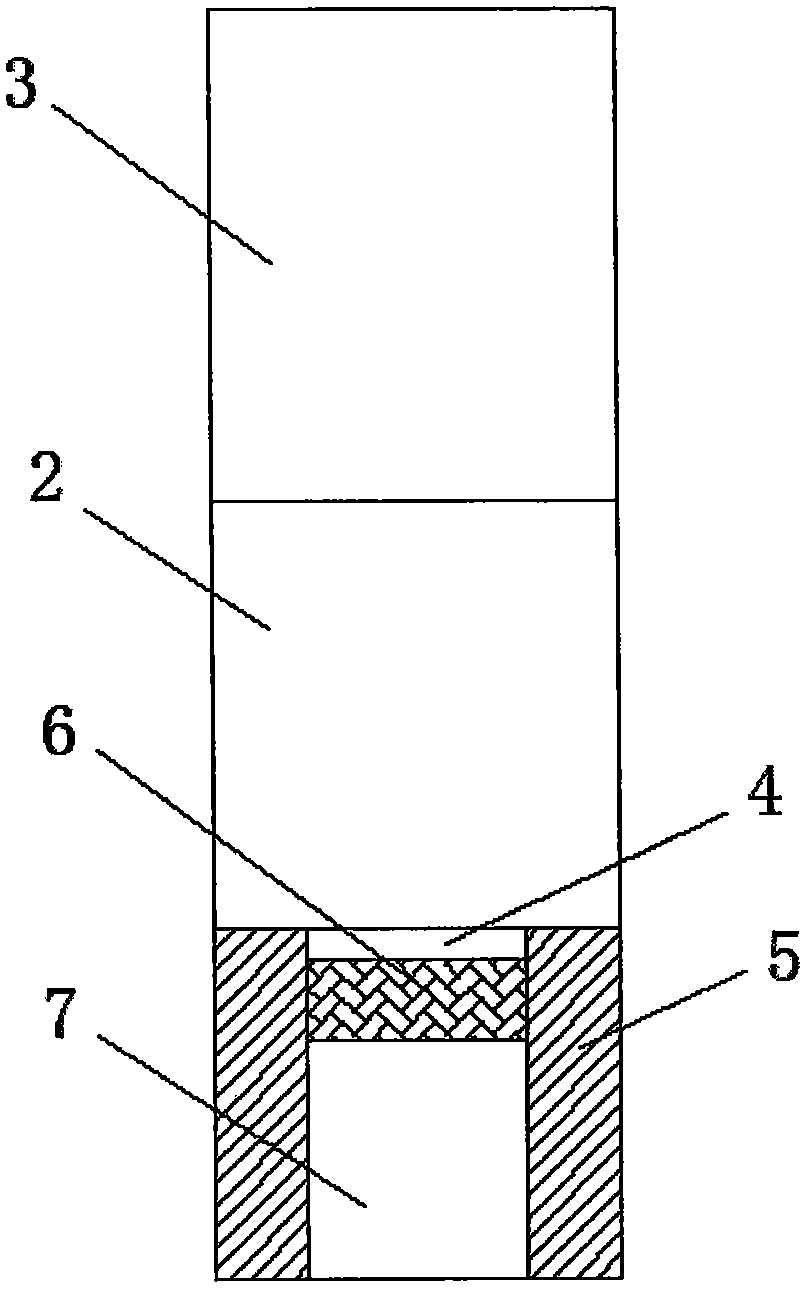

[0019] (II) adopting stage mining method to carry out rock drilling and blasting to the first mining stage to get out of mine (see figure 2 ), and finally in the first mining stage, rock drilling chambers, gobs, ore pillars and top layers are formed (see image 3 );

[0020] (III) If Figure 4 As shown in Fig. 1, rock drilling and blasting is adopted for mining in the second mining stage, and an isolation zone is reserve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com