A miniature silent pump and its working method

A working method, technology of silent pump, applied in the direction of pump, pump element, variable displacement pump parts, etc., to reduce the effect of knocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

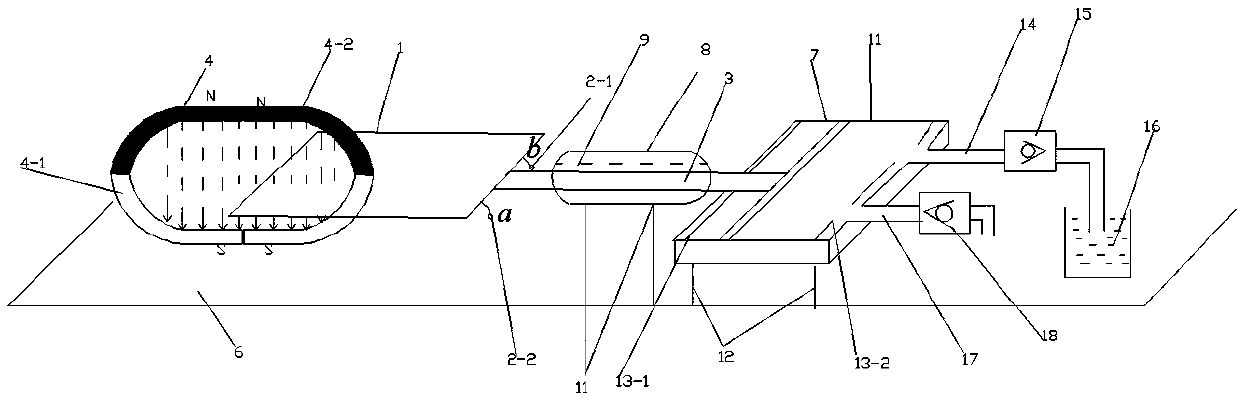

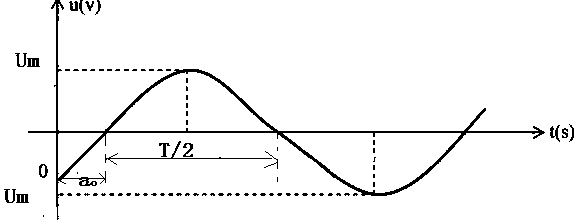

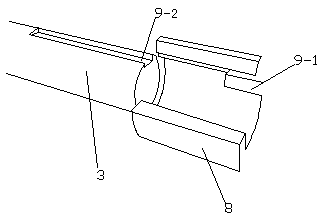

[0020] see figure 1 , the present invention provides a miniature silent pump, which includes a base 6, an O-shaped magnet 4, a rectangular wire frame 1 made of non-magnetic material, a connecting rod 3 and a piston pump 11; the O-shaped magnet is fixed on the base 6; The O-shaped magnet is made of two identical U-shaped magnets 4-1, 4-2 with the same magnetic poles close together in an O-shape; the rectangular wire frame 1 passes through the O-shaped magnet 4 on one side; the connecting rod 3 One end is connected to the midpoint of the opposite side of the rectangular wire frame 1, and the other end of the connecting rod 3 is connected to the piston 7 of the piston pump through a guide rail 8; the guide rail 8 is fixedly installed on the base through a bracket 10 6; N turns of rectangular air-core coils are wound on the rectangular wire frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com