Pump valve assembly and sphygmomanometer using same

A sphygmomanometer and component technology, applied in the direction of cardiac catheterization, etc., can solve problems such as complicated wiring, troublesome production, assembly and after-sales maintenance, and achieve the effects of space integration saving, reducing pipelines, and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

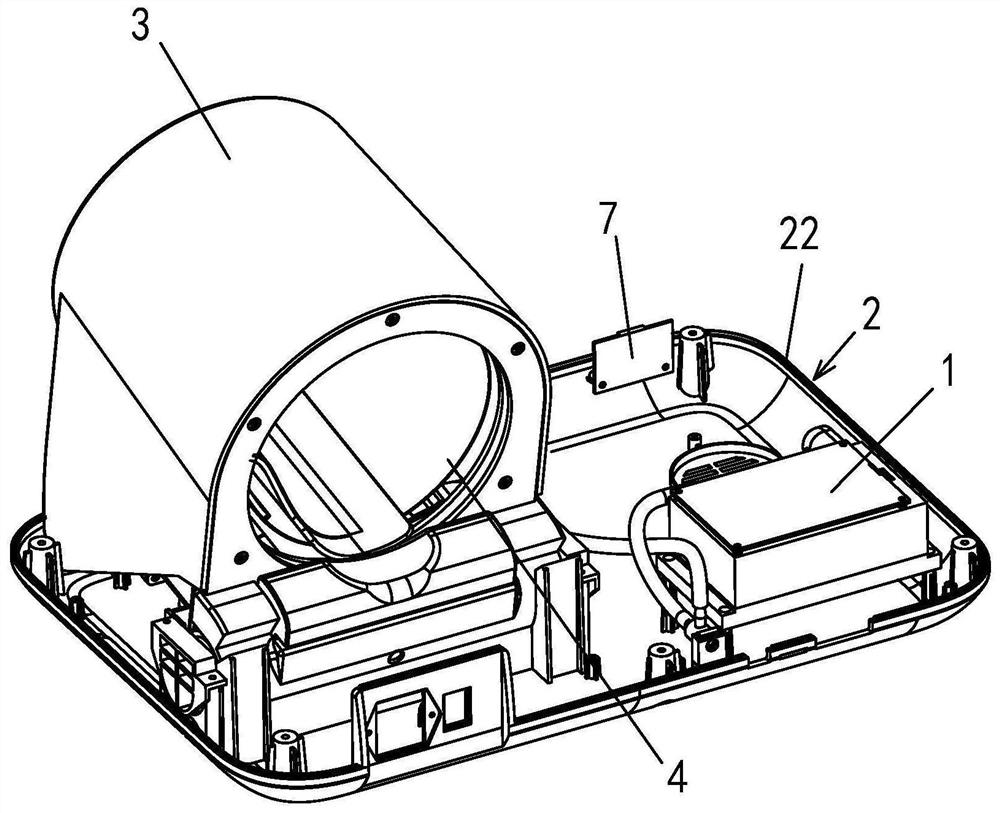

[0029] Embodiment one: see Figure 1~2 Shown:

[0030] A sphygmomanometer, a tunnel-type sphygmomanometer for fully automatic balloon inflation, see figure 1 As shown, it includes a seat body 2, an arm barrel 3 installed on the seat body 2, and an air bag assembly 4 arranged in the arm barrel 3, and also includes a pump valve assembly 1, and the assembly bracket 15 of the pump valve assembly 1 is fixedly installed on on the seat body 2.

[0031] The pedestal 2 is for example made up of the lower base plate 22 of the pedestal and the upper cover of the pedestal, figure 1 The upper cover of the middle base is in the state of being opened and removed. The assembly bracket 15 is fixedly installed on the seat body 2, specifically on the lower bottom plate 22 of the seat body, and is covered by the upper cover of the seat body.

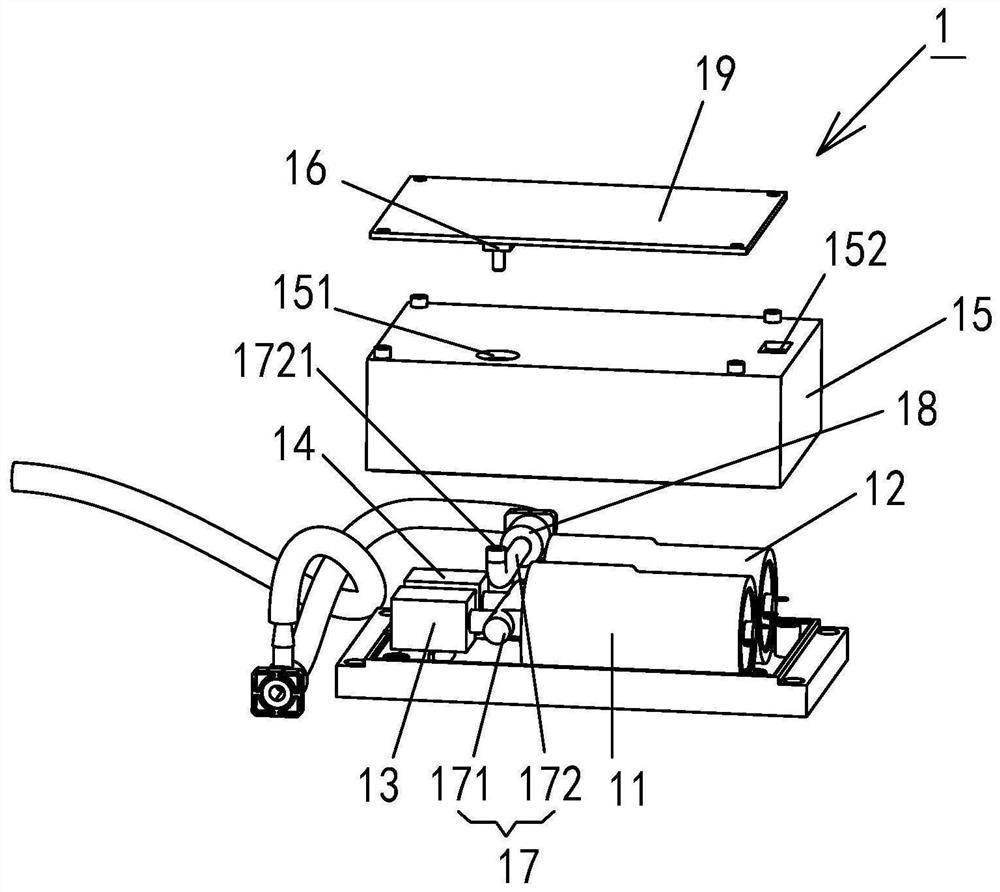

[0032] see figure 2 As shown, the pump valve assembly 1 includes a first air pump 11, a second air pump 12, a first air release valve 13, a second ai...

Embodiment 2

[0040] Embodiment two: see Figure 1~2 Shown:

[0041] A sphygmomanometer pump valve assembly 1, including a first air pump 11, a second air pump 12, a first air release valve 13, a second air release valve 14, a pipeline assembly and an assembly bracket 15, specifically the pump in Embodiment 1 The structure of the valve assembly 1 is the same and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com