Curve composite silencing drain pipe

A drainage pipe and mute technology, applied in the field of drainage pipes, can solve the problems of incompatibility, poor sound insulation effect, unsatisfactory mute effect, etc., and achieve good sound insulation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

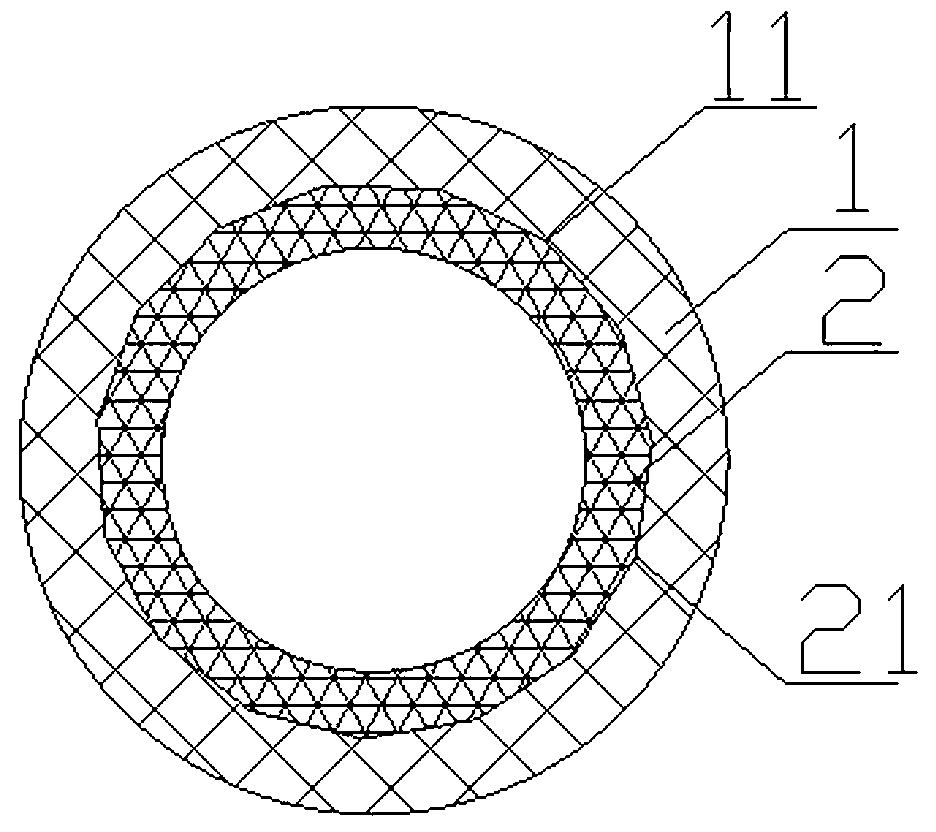

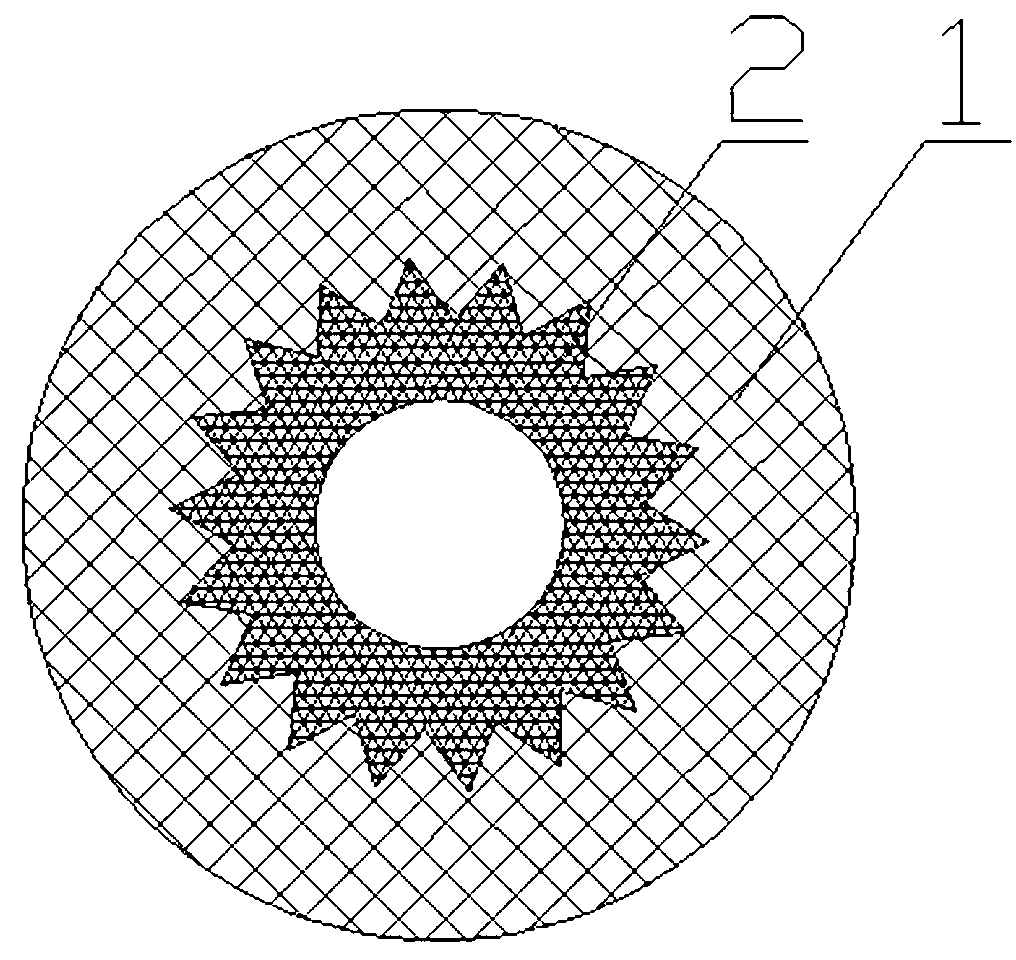

[0015] like figure 1 As shown, this embodiment is completed with a two-layer structure, wherein the outer ring layer is mainly made of PVC material, and the inner ring layer is mainly made of ABS material, wherein PVC adopts a unique formula: specifically, 6-10 10-25 parts of chlorinated polyethylene, 10-25 parts of iron ore powder, 0.8-4 parts of calcium stearate, 0.3-1 part of titanium dioxide, 0.1-3.5 parts of pigment; the unique formula used in the inner ring layer ABS: Specifically, add 15-20 parts of nano calcium carbonate to 100 parts of ABS; 0.2-1.5 parts of stearic acid; 10-15 parts of polyimide; 0.15-0.5 parts of compound lubricant; 2-10 parts of CPE; 3-5 parts of titanium dioxide; 0.15-0.5 parts of antioxidant. Put the materials of the above formula into the extruder, whether it is double-layer extrusion or multi-layer extrusion, it is necessary to put the ABS material into the innermost layer as the inner ring layer 2, and arrange the PVC material on the outermost...

specific Embodiment 2

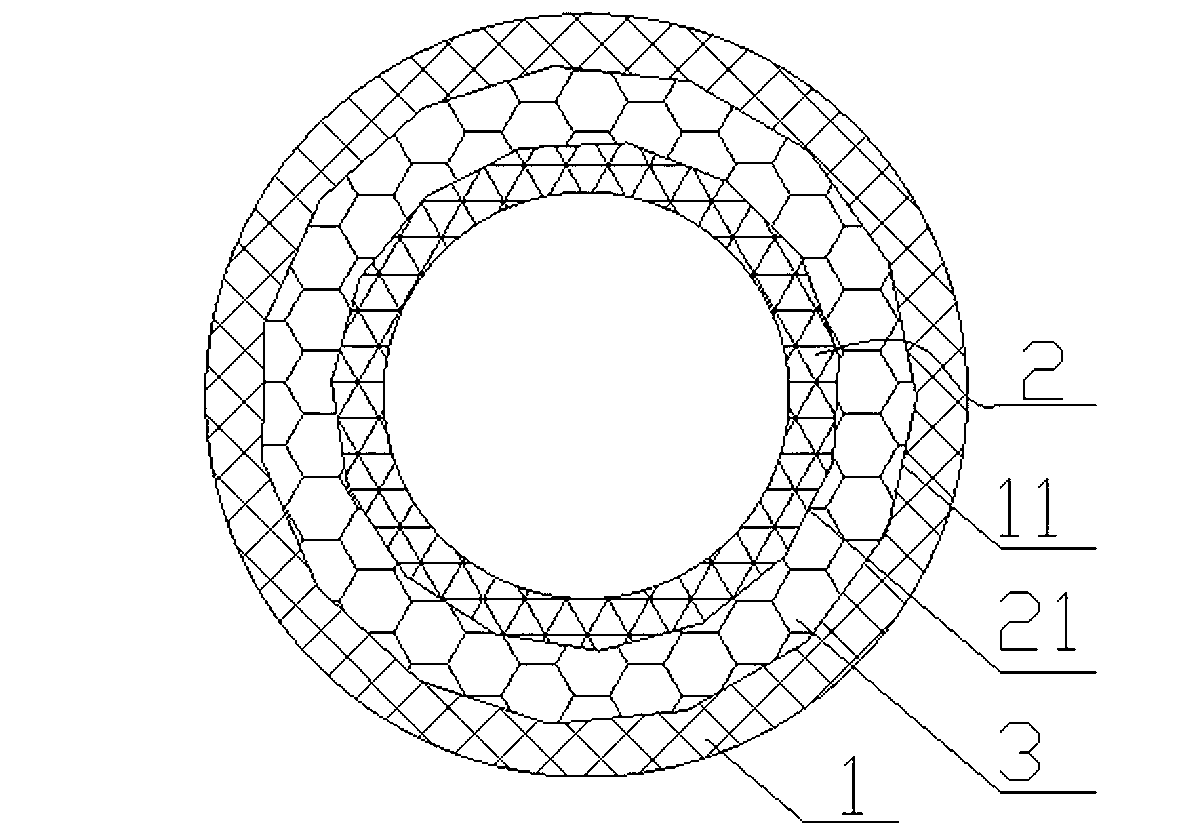

[0017] like figure 2 As shown, this patent has made a further improvement on the basis of the first solution. During the extrusion process, a vacuum grid 3 is arranged in the middle layer. The height of the vacuum grid 3 should not be too high, and should be kept at 1 / 4 of the wall thickness. At the same time, the vacuum grid adopts a polygonal structure to ensure vacuum in the space during the extrusion process. This method is suitable for thick diameter tubes, especially for some large diameter nozzles. For example, when the tube diameter is greater than 16CM, due to this A pipe with a large cavity and a large displacement. Therefore, more noise will be generated, and the previous solution cannot completely silence large-diameter pipes. When we adopt this solution, on the one hand, in addition to the reasons in the previous case, there is also vacuum sound insulation, and the vacuum grid The polygonal structure is used to reflect the sound from multiple angles, so as to ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com