Electrical percussive tool

An impact tool, electric technology, applied in the direction of lightweight impact tool, strike tool, manufacturing tool, etc., can solve the problems of bulky, complex manufacturing process, high price and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

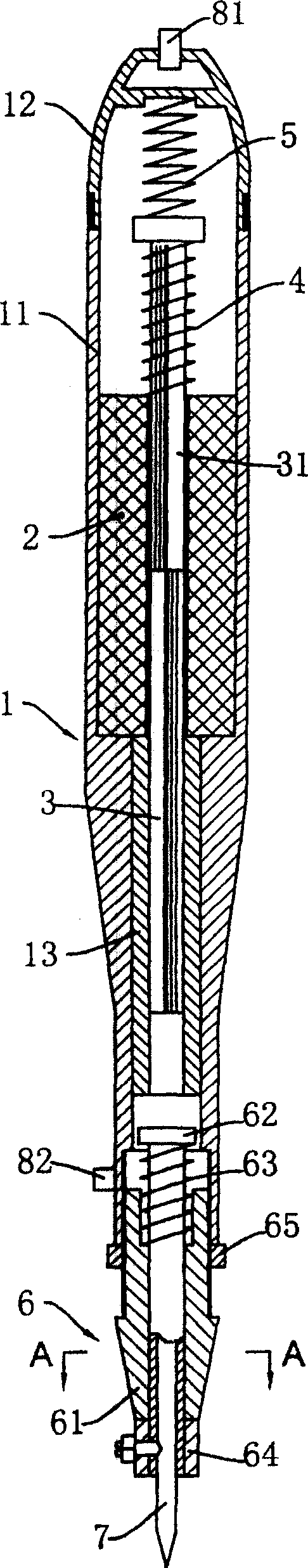

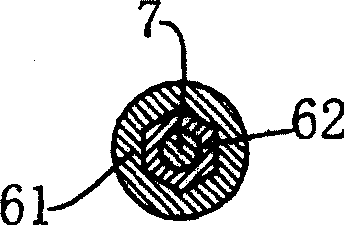

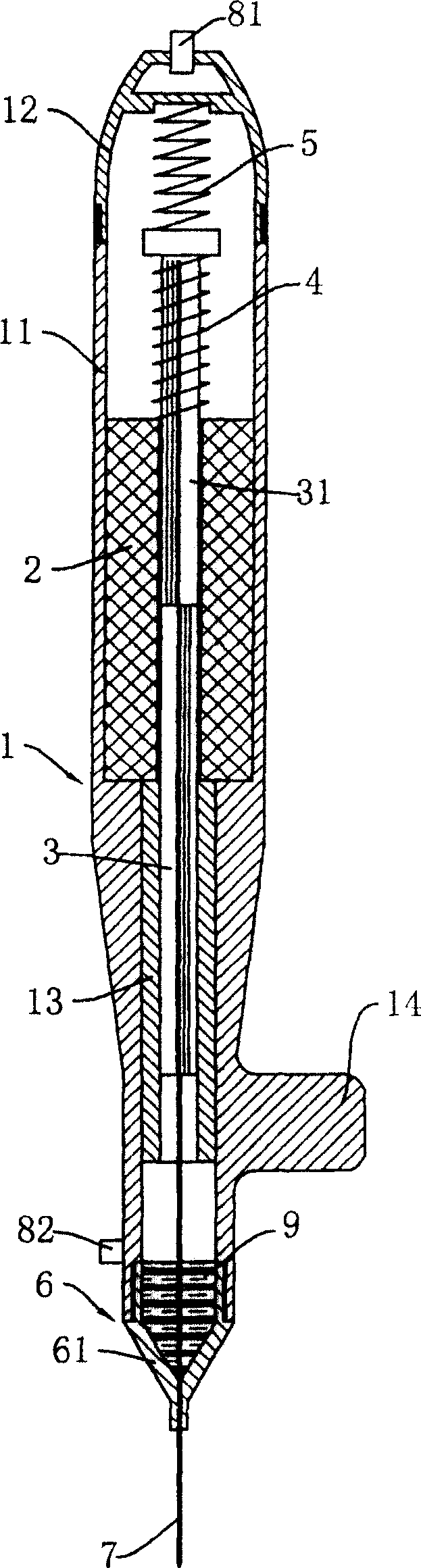

[0022] figure 1 Shown is an electric impact tool mainly used for engraving work, which includes a pen-shaped housing 1 with an open end and a closed end 12, the closed end 12 of the housing 1 is connected to the housing The body part 11 is screwed. The housing 1 is designed in the shape of a pen, which is not only attractive, but also convenient for handheld use. A power device for driving the tool to move linearly is installed in the housing 1, which is the core part of the impact tool. The open end of the housing 1 is installed with a tool holder device 6 for clamping a tool 7 .

[0023] The power device includes an electromagnetic coil 2 fixed inside the housing, the electromagnetic coil is connected to the pulse power supply device; the impact rod 3 can be moved axially along the guide part 13 located in the housing, and the impact rod 3 can move axially Pass through and both ends protrude from the inner cavity of the electromagnetic coil 2; the first elastic element 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com