Externally controlled two-position two-way pilot type proportional valve

A two-position, two-way, proportional valve technology, which is applied in the direction of fluid pressure actuators, servo motor components, mechanical equipment, etc., can solve the problems of poor low-pressure controllability and high-pressure stability, and achieve the goal of improving low-pressure controllability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

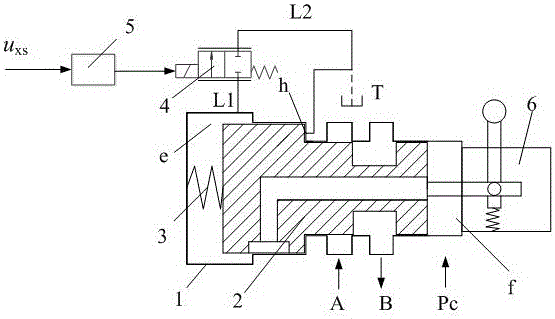

[0017] Example 1: figure 1 As shown, an externally controlled two-position two-way pilot-operated proportional valve includes a main valve body 1, a main valve core 2, a positioning spring 3, a pilot proportional valve 4, and a proportional amplifier 5. It is characterized in that: the positioning spring 3 and The main valve core 2 is coaxially arranged in the main valve body 1, the main valve body 1, the main valve core 2 and the positioning spring 3 constitute the main valve; the main valve core 2 and the main valve body 1 form three oil ports communicating with the outside world, That is, the first working oil port A, the second working oil port B, and the control oil port Pc, the opening amount of the first working oil port A is proportional to the displacement of the main valve core 2, the first working oil port A, the second working oil port Port B is respectively connected to the oil inlet chamber and oil return chamber of the actuator to introduce constant pressure oil...

Embodiment 2

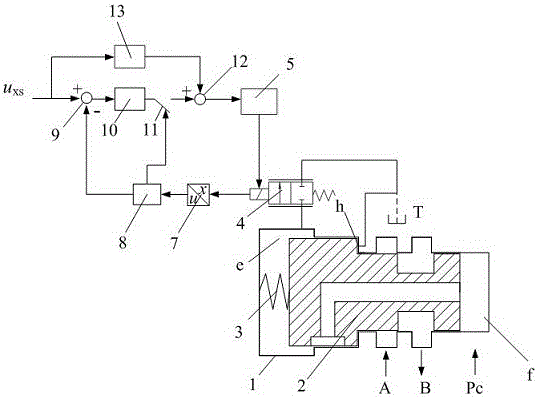

[0019] Example 2: figure 2 Among them, just as the structure and working principle of the externally controlled two-position two-way pilot proportional valve described in Embodiment 1, Embodiment 2 adds a pilot displacement sensor 7 and a pilot feedback signal amplifier 8 on the basis of Embodiment 1. , the first adder 9, closed-loop controller 10, electronic switch 11, the second adder 12, feed-forward controller 13; the output end of the pilot displacement sensor 7 is connected to the input end of the pilot feedback signal amplifier 8, the pilot feedback signal amplifier The output terminal of 8 is connected with the control terminal of electronic switch 11 and the input terminal of the first adder 9 respectively, setting signal u xs Be connected to the input end of the first adder 9 and feed-forward controller 13 simultaneously, the output end of the first adder 9 is connected to the input end of closed-loop controller 10; The output terminal is connected, the output ter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com