Universal control device for overdrive gearbox and method of use thereof

一种操纵装置、变速箱的技术,应用在机械控制装置、传动装置控制、仪器等方向,达到降低设计成本和制造加工成本、选挡可靠性高、易于制造装配的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

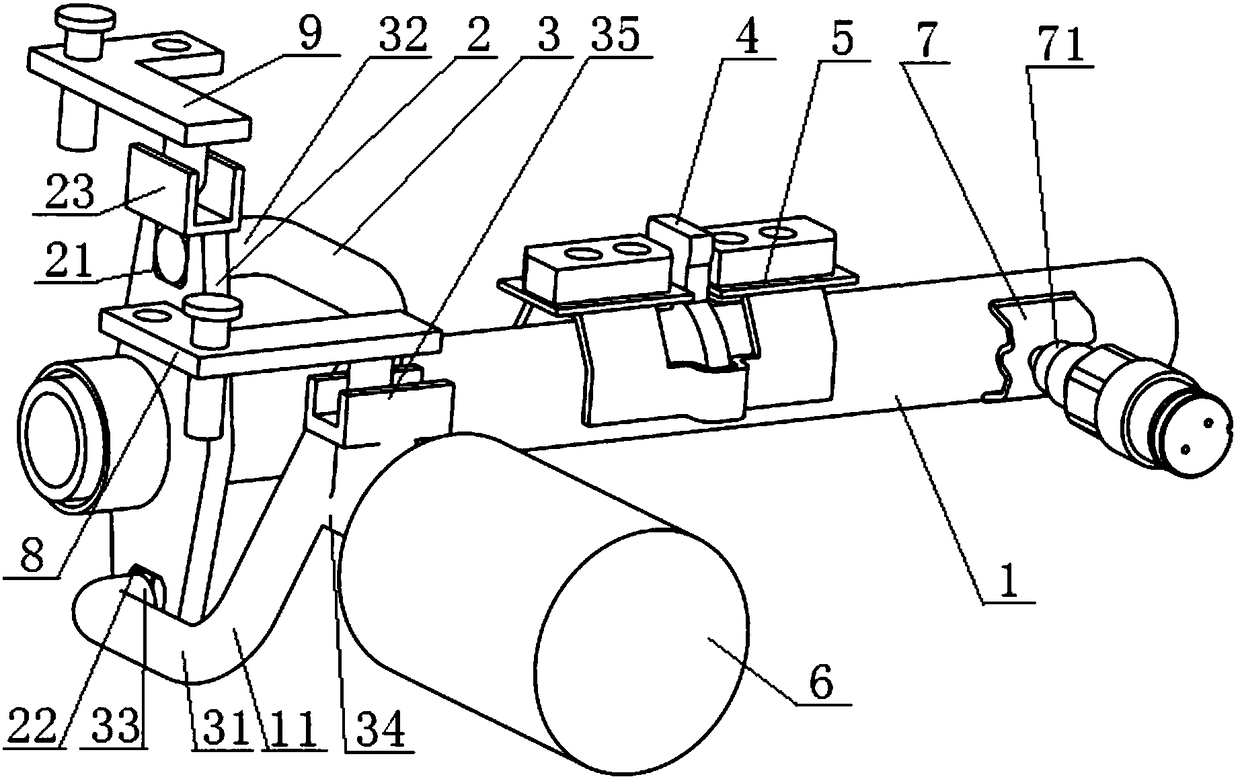

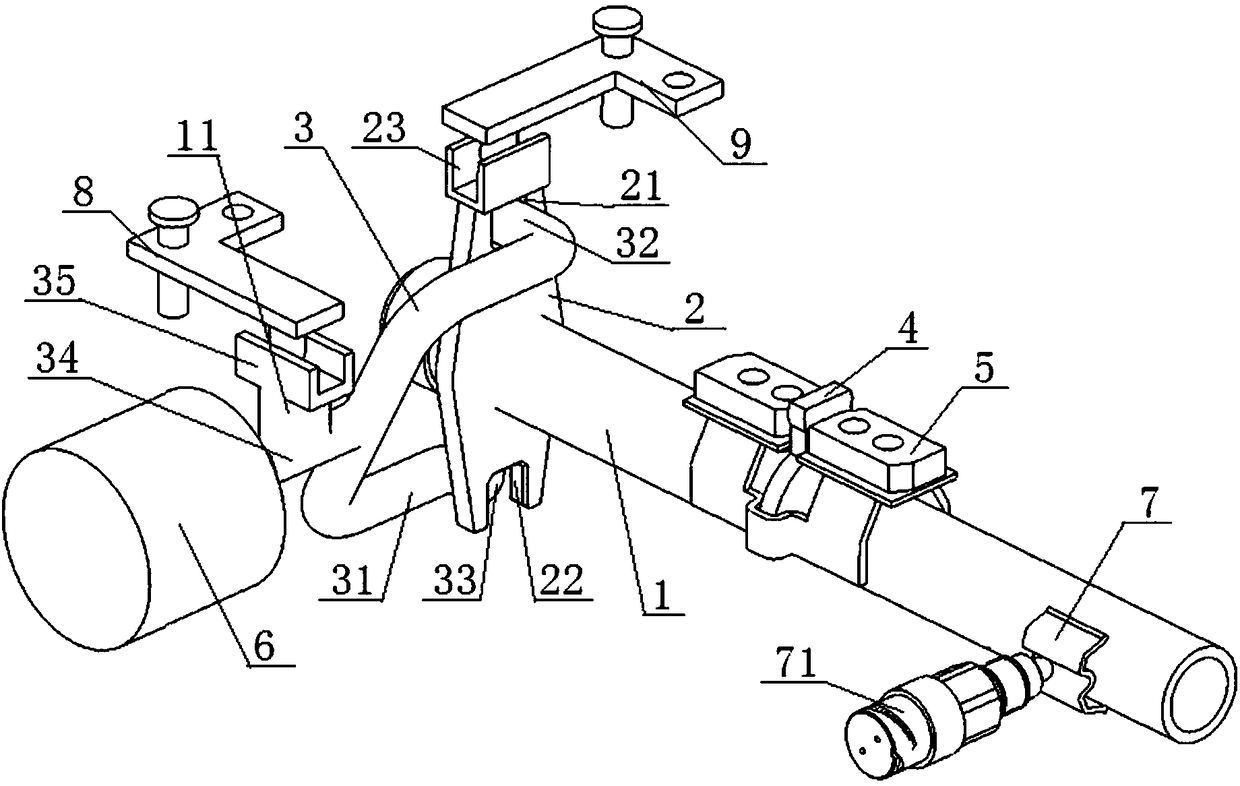

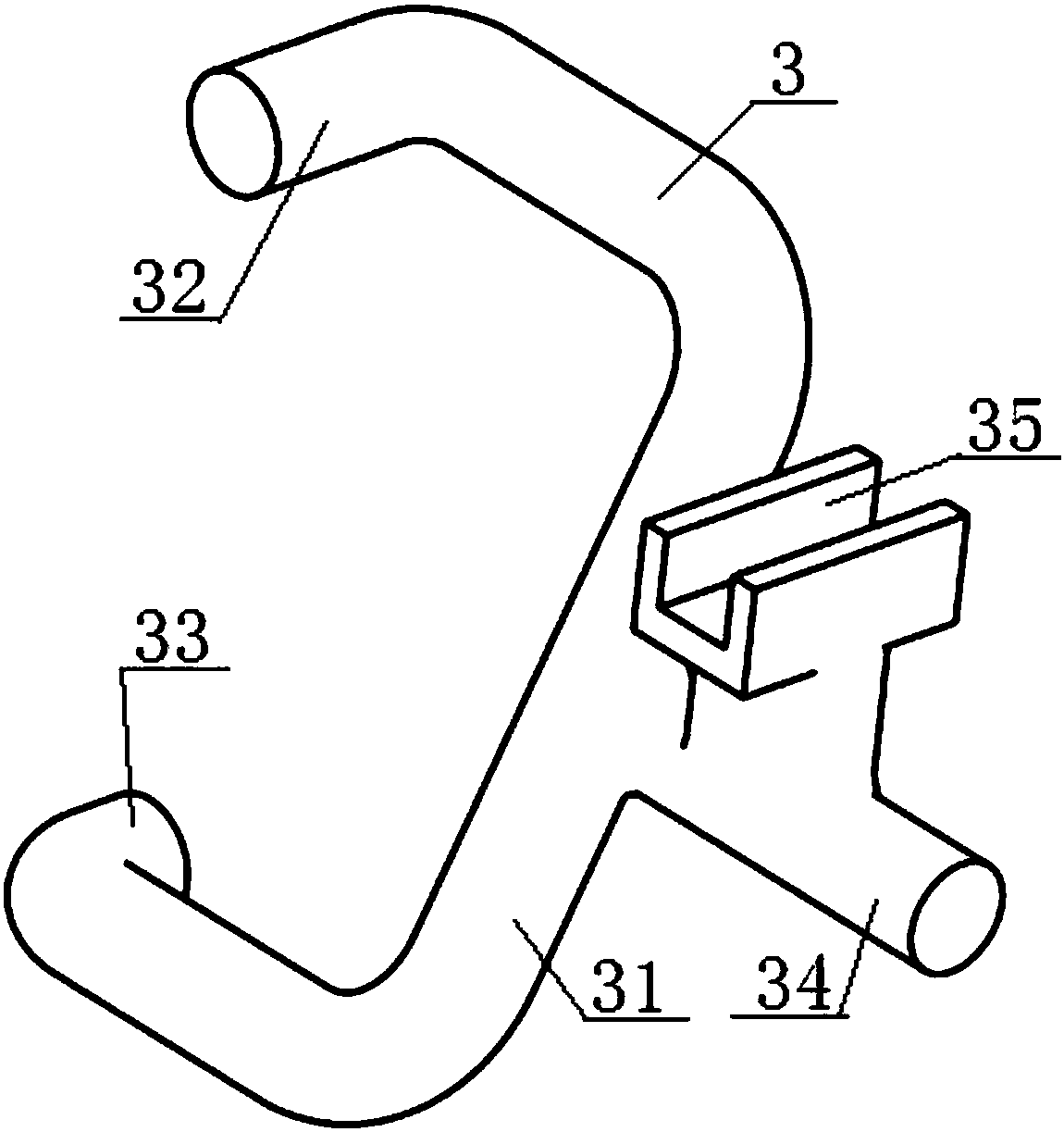

[0079] see Figure 1 to Figure 8 , a general operating device for an overdrive gearbox, comprising a gearbox selector shift shaft 1 and a selector shift rocker 2 and a selector shift dial 4 arranged on it, one end of the gearbox selector shift shaft 1 passes through The gear-selecting rocker arm 2 is respectively matched with the gear-selecting flexible shaft and the gear-shifting flexible shaft. The flexible shaft of the gear shifts through the overdrive gear conversion device 11 and the gear selection rocker 2. The overdrive gear conversion device 11 includes a shift fork 3, and the upper end of the shift fork 3 is connected to the gear selection rocker arm. 2, the lower end of the shift fork 3 and the lower end of the selector rocker arm 2 are in drive fit; the shift fork 3 includes a U-shaped fork lever 31, a general gear selector lever 32, a direct gear overdrive The selector lever 33 and the transmission push rod 34, the general gear selector lever 32 and the direct gea...

Embodiment 2

[0093] Embodiment 2 is basically the same as Embodiment 1, and its difference is:

[0094] The overdrive gear conversion device 11 also includes a shift booster 6, the power output end of the shift booster 6 is fixedly connected to one end of a transmission push rod 34, and the other end of the transmission push rod 34 is connected to a U-shaped The middle part of the fork rod 31 is fixedly connected, the middle part of the transmission push rod 34 is in transmission cooperation with the shift flexible shaft, and the shift booster 6 is a pneumatic device;

Embodiment 3

[0096] Embodiment 3 is basically the same as Embodiment 1, and its difference is:

[0097] The gear selection and shift shaft 1 of the gearbox is a circular tube structure, and the gear selection rocker 2 and the shift dial 4 are welded on the outer wall of the gear selection and shift shaft 1 of the gearbox. An interlock seat 5 is sheathed on the shaft 1, and the selector shift dial 4 passes through the interlock seat 5 and then cooperates with the shift guide block in transmission.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com