Power-driven water feeding valve for passenger train

A railway passenger car, electric technology, applied in the direction of valve details, multi-way valves, valve devices, etc., can solve the problems of inaccurate switch position control, incomplete opening, high labor intensity, etc., to reduce labor intensity of employees, prevent freezing, The effect of improving the technical level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

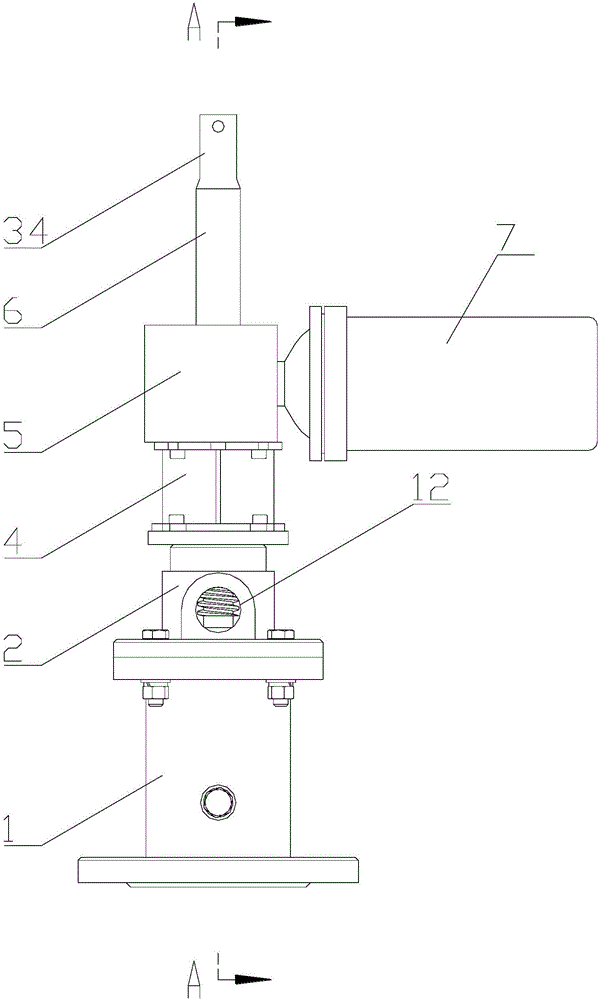

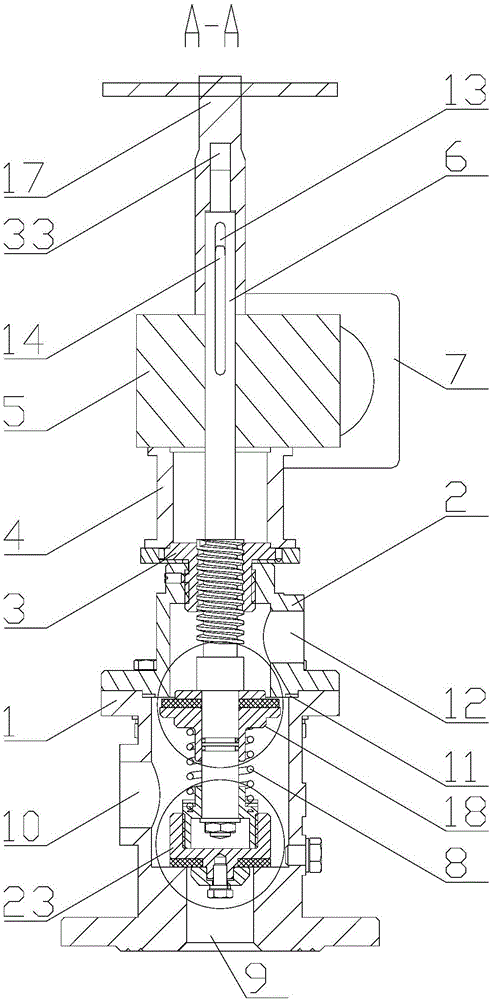

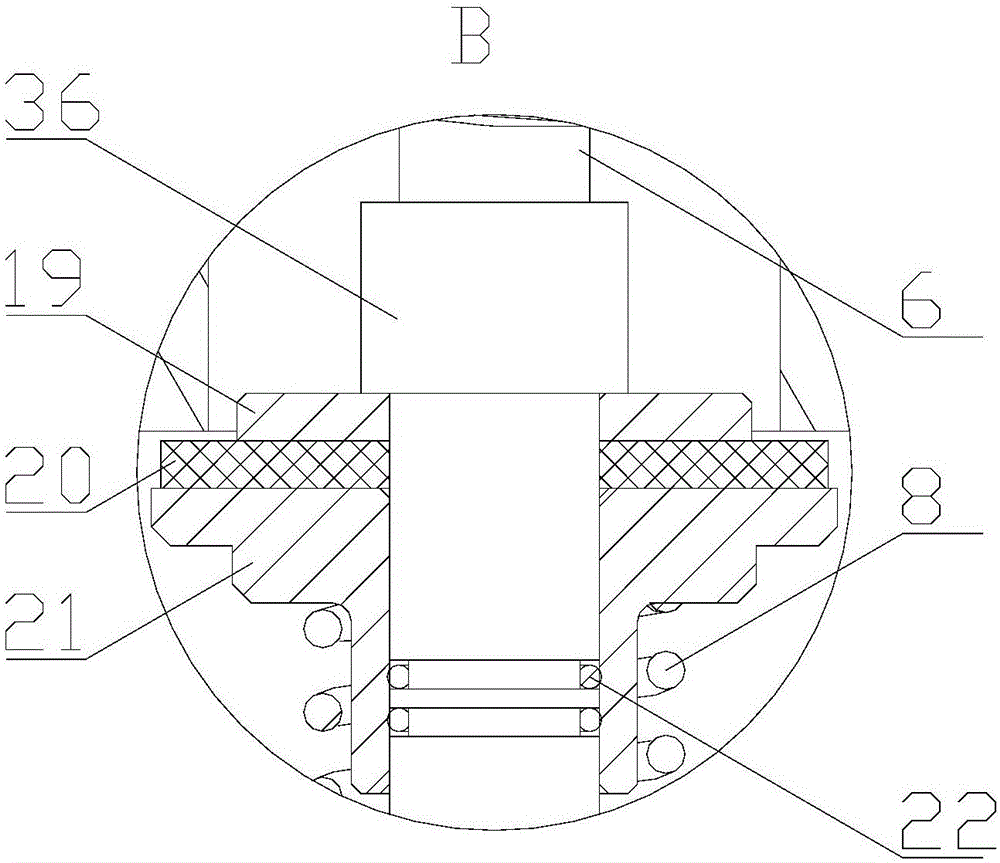

[0017] Such as Figure 1 to Figure 5 As shown, the electric water supply valve for railway passenger cars includes a valve body 1, a valve cover 2, a connecting nut 3, a connecting flange 4, a worm reducer 5, a valve stem 6, a motor 7, and a spring 8; in the valve body 1 A water inlet 9 is provided at the bottom; a water outlet 10 is provided on the side wall of the valve body 1; the valve cover 2 is fixed above the valve body 1, and between the valve body 1 and the valve cover 2 A bonnet sealing ring 11 is provided between them; a water return port 12 is provided on the side wall of the bonnet 2, and the connecting nut 3 is screwed in the top opening of the bonnet 2, and the connecting nut 3 is threaded inside and outside. ,, the external thread is connected with the bonnet 2, and its relative rotation is limited by the set screw 31; the connecting flange 4 is arranged above the bonnet 2; the connecting flange 4 connects the worm reducer 5 and the bonnet 2 The device also pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com