Throttling structure for long-distance pipeline

A long-distance pipeline and flow channel technology, applied in the field of gas regulating devices, can solve problems such as gas transmission stagnation, gas reverse channeling, etc., and achieve the effects of reducing resistance, reducing weight, and convenient and flexible adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

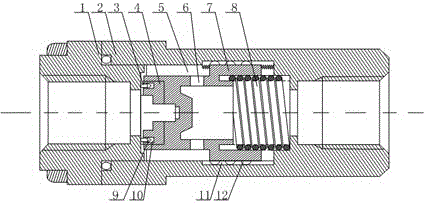

[0020] Such as figure 1 As shown, this embodiment includes a valve body 2, a tubular movable block 7 with one end closed, and a connecting head 1 whose end extends to the inside of the valve body 2. The connecting head 1 communicates with the inside of the valve body 2, and the closed end of the movable block 7 The outer diameter is smaller than the outer diameter of the open end, and there is a chute on the inner wall of the middle part of the valve body 2, and the open end of the movable block 7 is slidably arranged in the chute, and the annular space between the closed end of the movable block 7 and the chute forms a flow channel 5 , a contact block 4 is provided on the closed end face of the movable block 7, a packing ring 3 is provided on the extension end of the connecting head 1, and a protruding part 9 is installed on the packing ring 3, and the protruding part 9 It is an elastic rubber block with a triangular shape, and on the end surface of the contact block 4, there...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com