Redundant structure vortex flowmeter

A technology of vortex flowmeter and redundant structure, which is applied in the direction of volume/mass flow generated by mechanical effect, and through detecting the dynamic effect of fluid flow, etc., which can solve the adverse effects of enterprises, affect the production process, and ordinary flowmeters cannot separate Problems such as two-way signals can improve detection accuracy and stability and reduce on-site construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

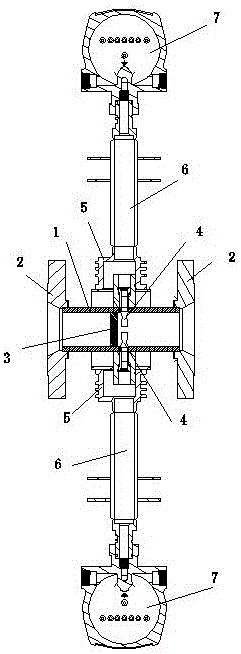

[0011] Embodiment 1: A vortex flowmeter with a redundant structure, including a flowmeter pipeline 1, a connecting flange 2 installed at both ends of the flowmeter pipeline 1, a vortex generator 3 arranged in the flowmeter pipeline 1, and a vortex generator Two symmetrical sensors 4 are arranged on the rear side of the body 3, and the two sensors 4 are arranged symmetrically up and down and spaced apart. , the sensor 4 exposed to the outer end of the flowmeter pipeline 1 is installed in the flowmeter housing 5, the flowmeter housing 5 is connected to the bracket 6, and the bracket 6 is connected to the flowmeter head 7. One of the sensors 4 is connected to the DCS through an electronic circuit for normal production control; the other sensor 4 is connected to the ESD through an electronic circuit for an emergency shutdown system.

Embodiment 2

[0012] Embodiment 2: With reference to Embodiment 1, two sensors 4 are simultaneously connected to the DCS through an electronic circuit, and the deviation of the two signals ±1% is used as a diagnostic means to improve detection accuracy.

Embodiment 3

[0013] Embodiment 3: Referring to Embodiment 1, one is for standby and the other is for use. When one of the sensors is damaged, the other can detect and provide accurate flow signals, which improves the stability of enterprise production.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com