Method for implementing fabricated concrete house building by using members with novel connecting ends

A concrete and prefabricated technology, applied in the direction of building components, buildings, building materials, etc., can solve the problems of large investment in concrete prefabricated component processing plants, difficulties in market acceptance, and structural hidden dangers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

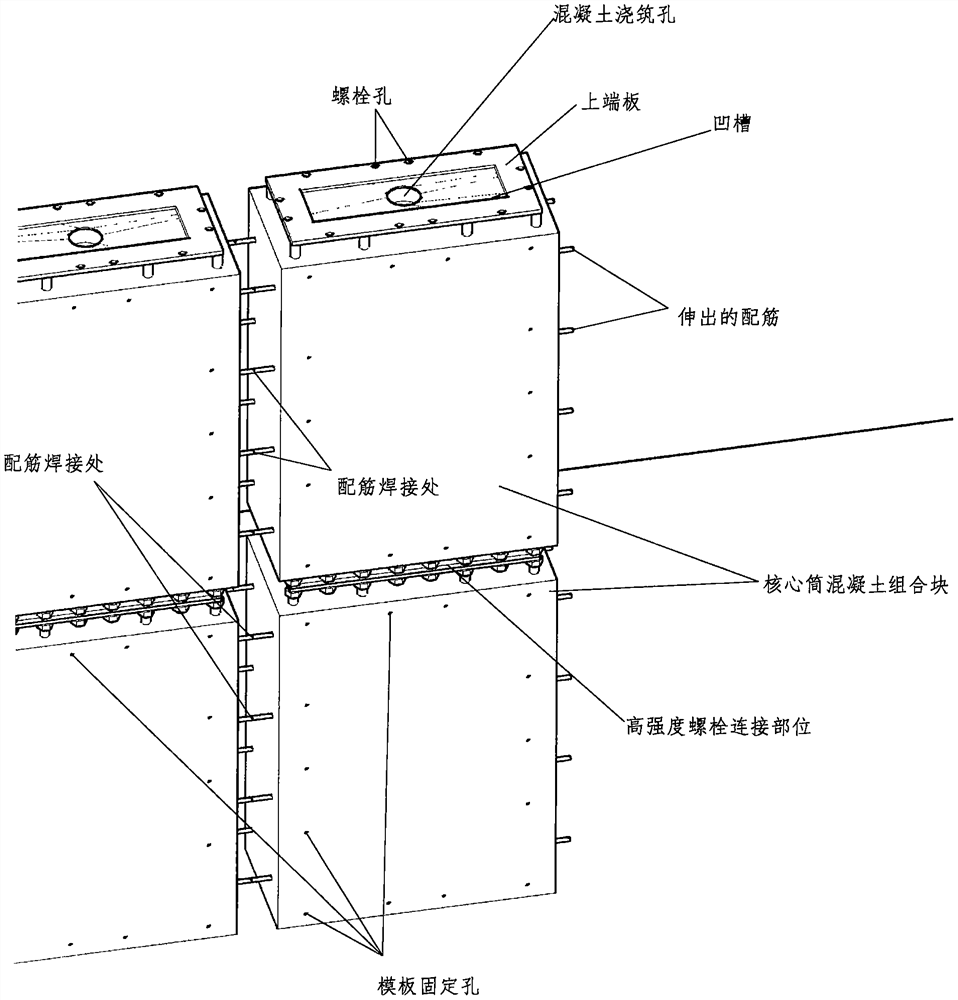

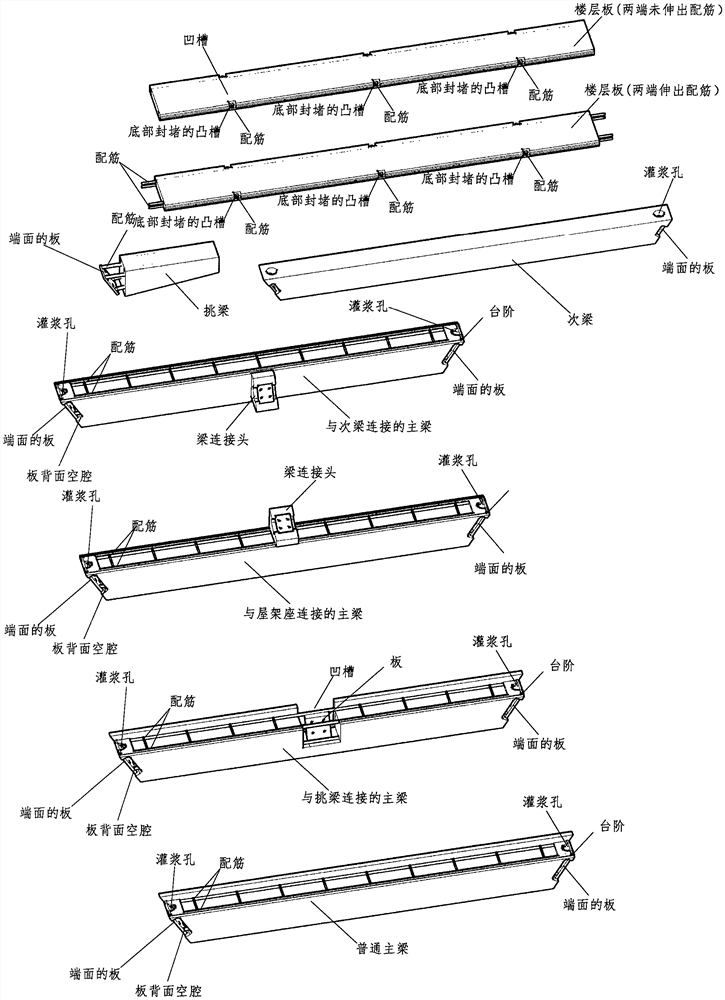

[0021] Below, in conjunction with accompanying drawing, specifically describe how to implement building house according to the present invention:

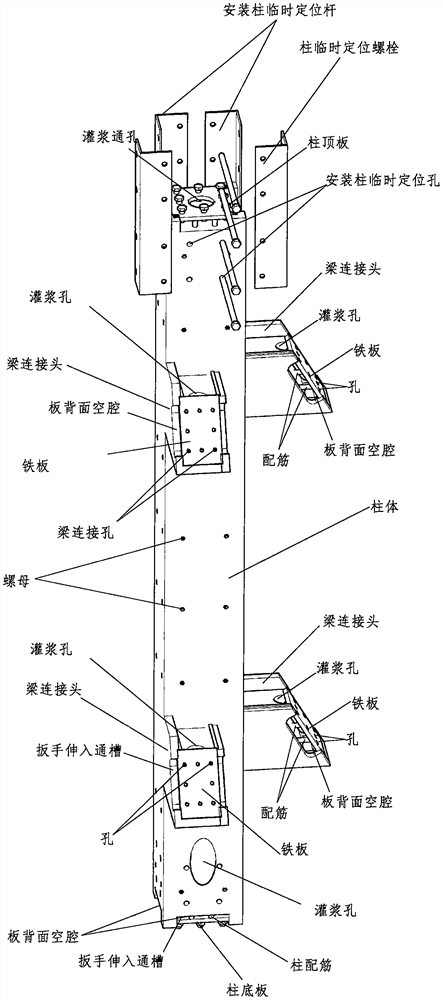

[0022] figure 1 The characteristics of the column are as follows:

[0023] 1. The upper and lower ends of the column are plates welded together with the reinforcement of the concrete in the column. There are through holes on the plate that can pass through high-strength bolts, and there is a large hole in the middle of the plate that can pass through the poured concrete. , There is a cavity formed by leaving a certain distance from the back of the plate to the end face of the concrete. In this cavity, bolts passing through the iron plate of the adjacent column can be installed to connect the two plates to each other as a whole.

[0024] 2. The connection between the column and the beam is provided with a beam connector protruding from the column. The structure of the end of the connector is similar to that of the column: the end f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com