Water-saving type fabricated concrete manure ditch and mounting method thereof

An installation method and prefabricated technology, applied in the field of water-saving prefabricated concrete manure ditch and its installation, can solve the problems of high construction cost, groundwater pollution, slow construction speed, etc., to reduce prefabricated production costs and on-site construction costs , the effect of fast construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

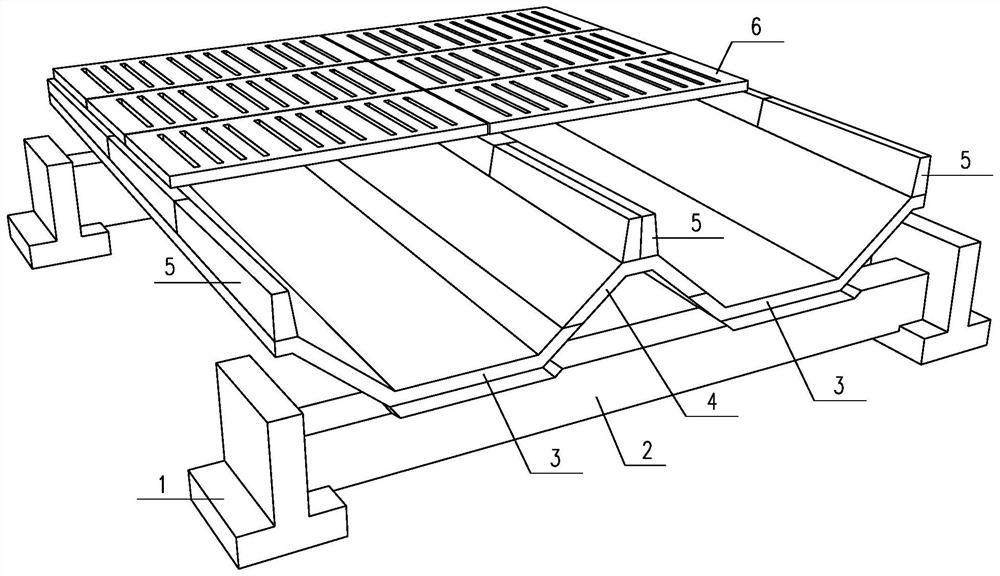

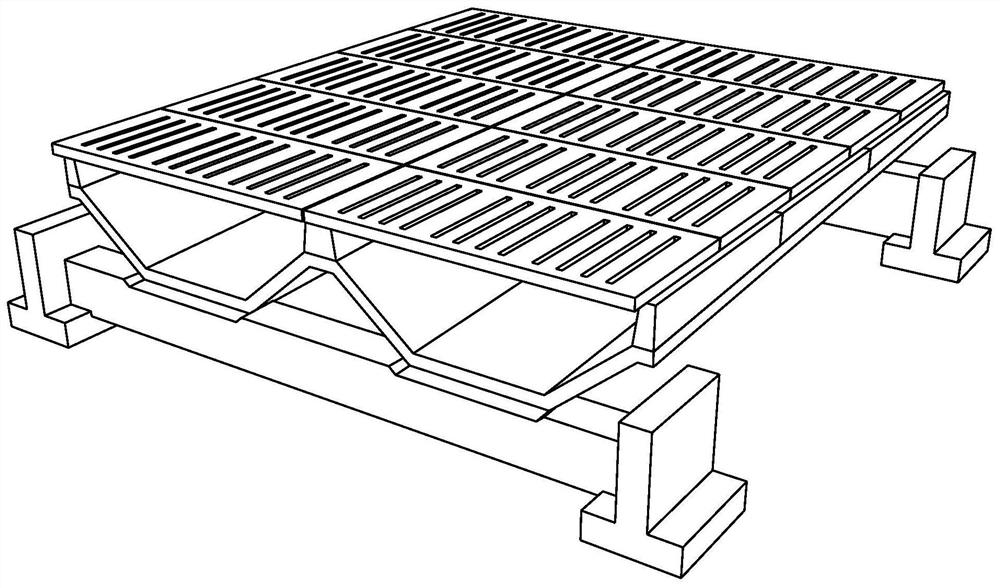

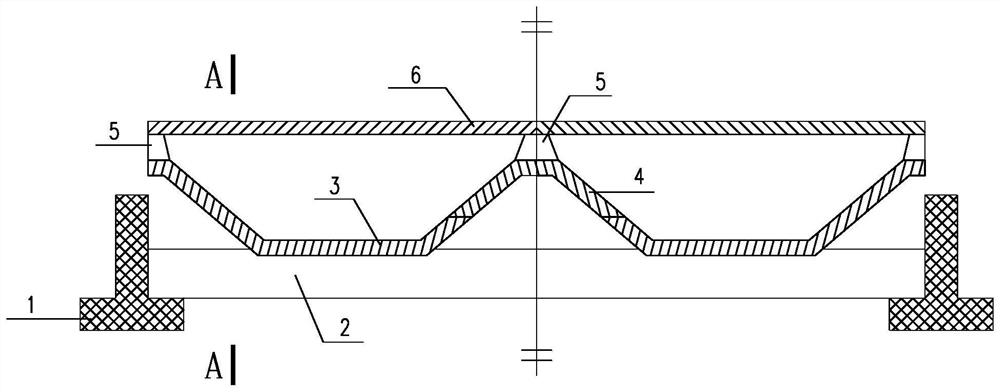

[0052] The present invention is described in detail below in conjunction with accompanying drawing description:

[0053] like Figure 1-12 Said: Water-saving prefabricated concrete manure ditch, which includes the following prefabricated components,

[0054] The prefabricated foundation 1 is provided with multiple pairs placed in the excavated foundation trench in an orderly manner from front to back;

[0055] The prefabricated slope adjusting beam 2 is erected between the paired two prefabricated foundations 1;

[0056] The first prefabricated folded plate 3, two first prefabricated folded plates 3 are arranged mirror-symmetrically and erected between two adjacent prefabricated slope adjustment beams 2;

[0057]The second prefabricated folded plate 4 is located between two adjacent prefabricated slope adjustment beams 2 and the left and right sides of the second prefabricated folded plate 4 are erected on the corresponding two first prefabricated folded plates 3;

[0058] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com