Manual pressure reducing valve service life test system

A technology of life test and pressure reducing valve, which is applied in the field of test system, can solve the problems of inability to realize intelligent and automatic control, unadjustable time relay, and single life test system, so as to solve the problem of life test, and the number of tests can be recorded and reduced. noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

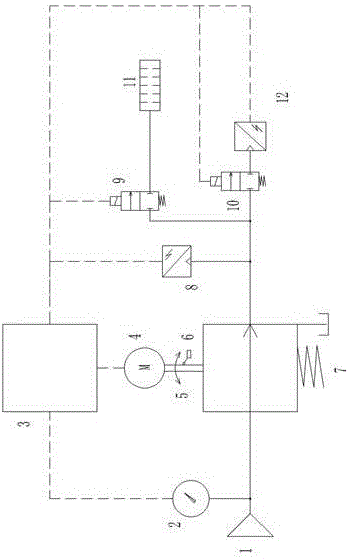

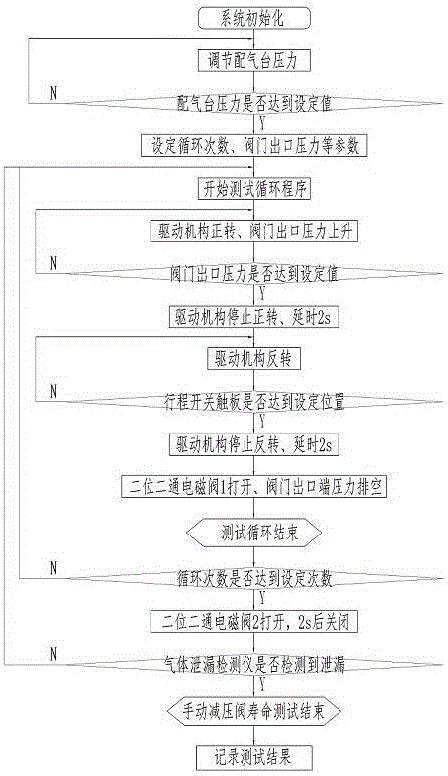

[0011] Below in conjunction with accompanying drawing, to accompanying drawing of the present invention figure 1 and figure 2 For further clarification:

[0012] figure 1 : Manual decompression valve life test system, characterized in that the tested manual decompression valve (7) is fixed on the test bench through a hoop, and the driving motor (4) passes through a high-speed ratio reduction box, a coupling, and a connecting sleeve The cylinder, pressure regulating device (5) and travel switch (6) are connected with the tested manual pressure reducing valve; the inlet port of the tested manual pressure reducing valve (7) is connected to the gas source (1) of the gas distribution platform through a pipeline, and the pipeline is connected Connect the electric contact pressure gauge (2); the outlet port of the manual pressure reducing valve (7) to be tested is connected in parallel with three sets of valves through pipelines, one set is a pressure relay (8), and the other set ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com