Reciprocating double synchronous assembly system based on hopkinson pressure rod

An assembly system, reciprocating technology, used in measuring devices, using stable tension/pressure to test the strength of materials, instruments, etc., can solve problems such as experimental failure, the temperature of the sample and transmission rod is greatly affected, and the loading rod is heated. , to achieve the effect of simple and quick installation of casing, good synchronization effect and good thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

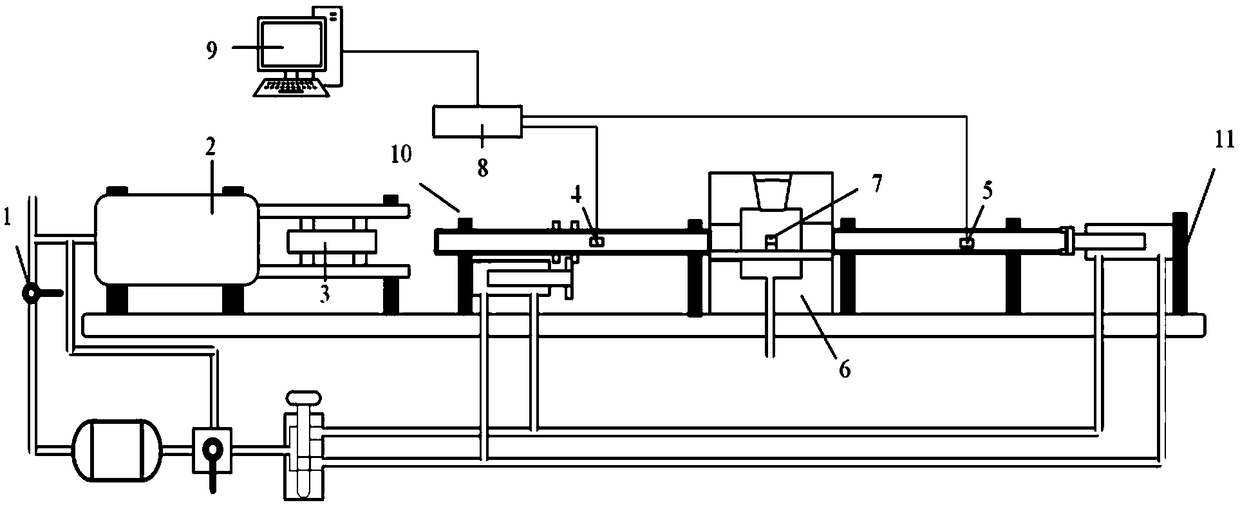

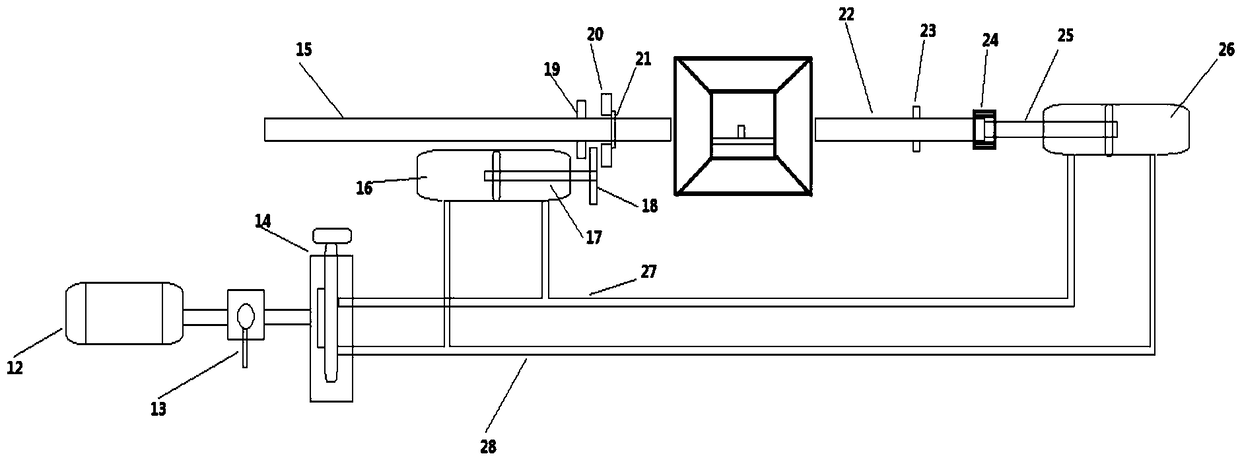

[0020] This embodiment is a reciprocating dual synchronous assembly system based on Hopkinson pressure rods, including a heating furnace 29, an independent synchronous gas chamber 12, a three-way synchronous launch valve 13, a synchronous manual valve 14, an injection rod synchronous piston 16, an injection rod Synchronous piston push rod 17, top piece 18, pull back snap ring 19, collar 20, incident rod limit snap ring 21, transmission rod limit snap ring 23, connecting sleeve 24, transmission rod synchronous piston push rod 25, transmission rod Synchronize piston 26, push air pipe 27 and pull back air pipe 28. in:

[0021] The output port of the synchronous air chamber 12 communicates with the input port of the three-way synchronous emission valve 13 through a pipeline. The two output ports of the three-way synchronous launch valve 13 communicate with the two input ports of the synchronous manual valve 14 respectively. The two output ports of the synchronous manual valve ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com