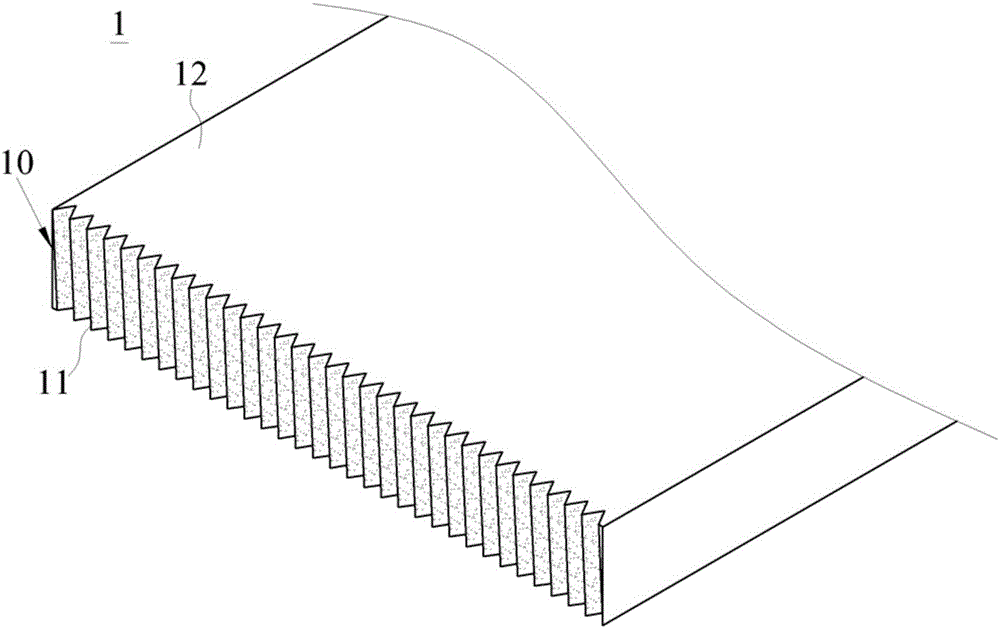

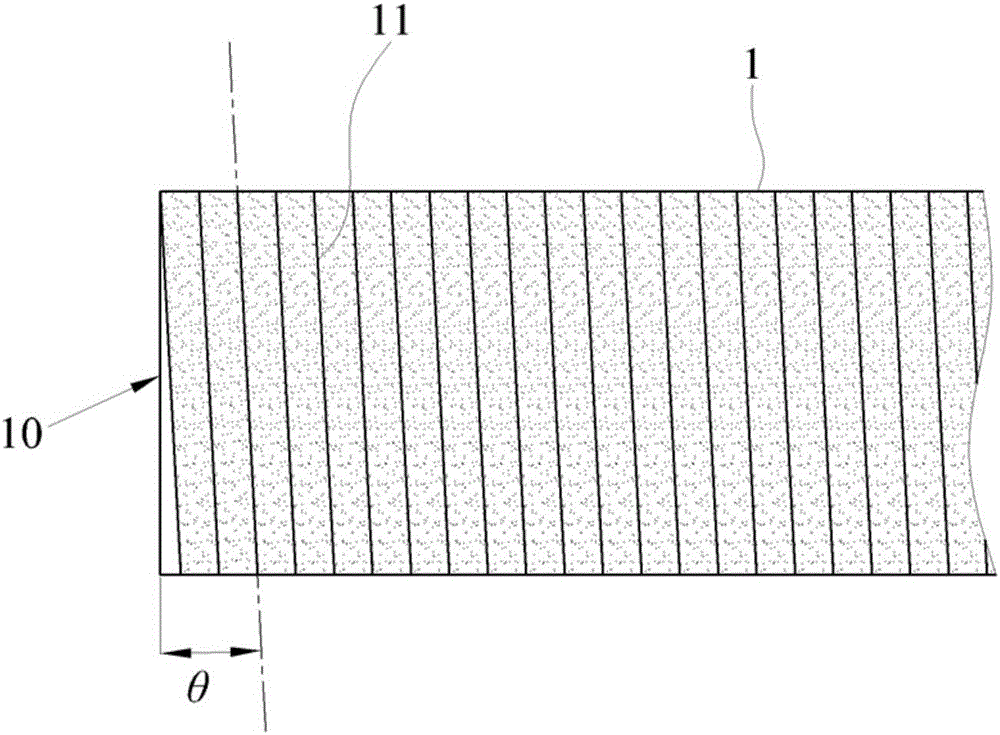

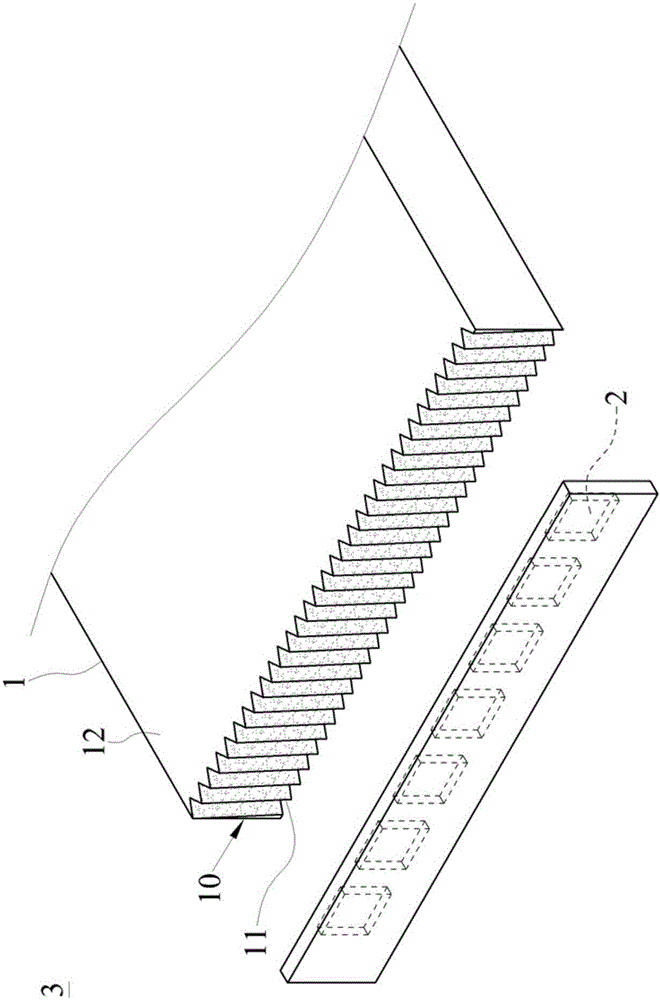

Light guide plate capable of eliminating hot spot phenomenon and backlight module thereof

A technology of backlight module and light guide plate, applied in the field of light guide plate, can solve the problem of hot spot phenomenon of the light guide plate, and achieve the effect of increasing the light emission angle, the effect of real and effective dimming, and the effect of eliminating uneven brightness and darkness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention is further illustrated below by means of examples, but the present invention is not limited to the scope of the examples.

[0041] Light has extremely sensitive physical characteristics, and a slight structural change may cause the divergence angle to be completely opposite to the expected result. Therefore, many structural details must be paid attention to when designing the light guide plate. In the initial stage of developing the light guide plate, in order to know the effect of the light-spreading microstructure and the rough surface on the light-incident side surface on the incident light angle, the inventors used four groups of different light guide plates for experimental comparison. The side surface does not have a light-spreading microstructure and is a light guide plate with a polished mirror surface; the second group is a light-guide plate that does not have a light-spreading tooth on the light-incident side surface but is a rough matte s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com