Sub-pixel boundary rapid detection method for cutter measurement

A detection method and sub-pixel technology, applied in the field of industrial vision, can solve problems such as complex calculation and difficulty in achieving real-time response, and achieve the effects of improving resolution, simple use and implementation, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

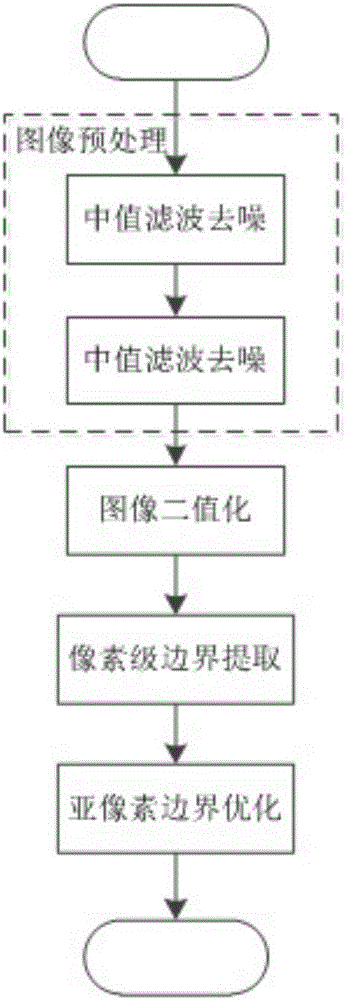

[0030] Such as image 3 As shown, the sub-pixel boundary detection method for tool measurement mainly includes four steps: image preprocessing, image binarization, pixel-level boundary extraction and sub-pixel boundary optimization.

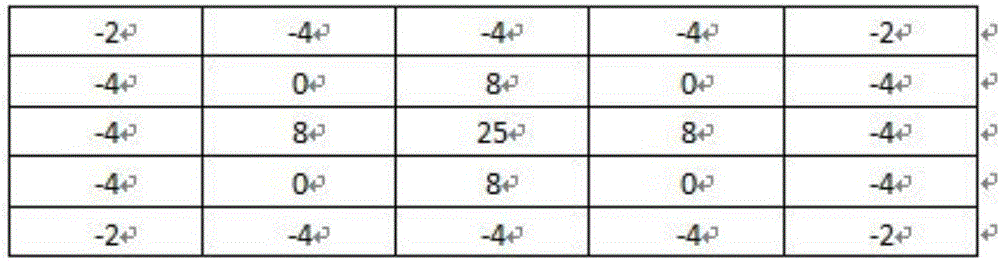

[0031] Input a picture of the tool to be measured, first use the median filter algorithm to filter out the salt and pepper noise in the image, and then use figure 1 The shown 5*5 discrete Log boundary enhancement operator template performs boundary enhancement on the image to be tested.

[0032] After the preprocessed picture, the threshold T of image binarization is dynamically determined based on the OTSU algorithm. If the gray value of the image is greater than T, it is 255, otherwise it is 0.

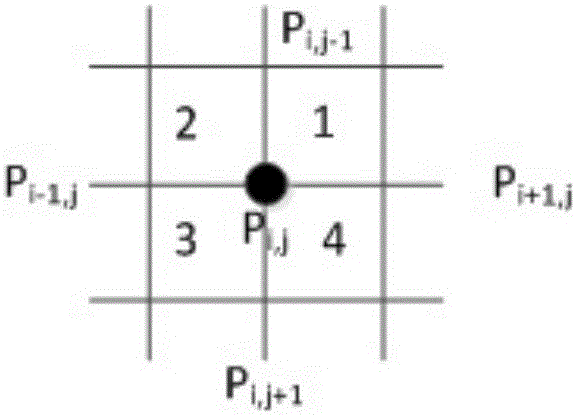

[0033] All boundaries in the image are clustered based on connectivity criteria. In order to eliminate the short boundary caused by noise...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com