Soft carbon graphite composite negative electrode material, preparation method and lithium ion battery

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor sample uniformity and processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

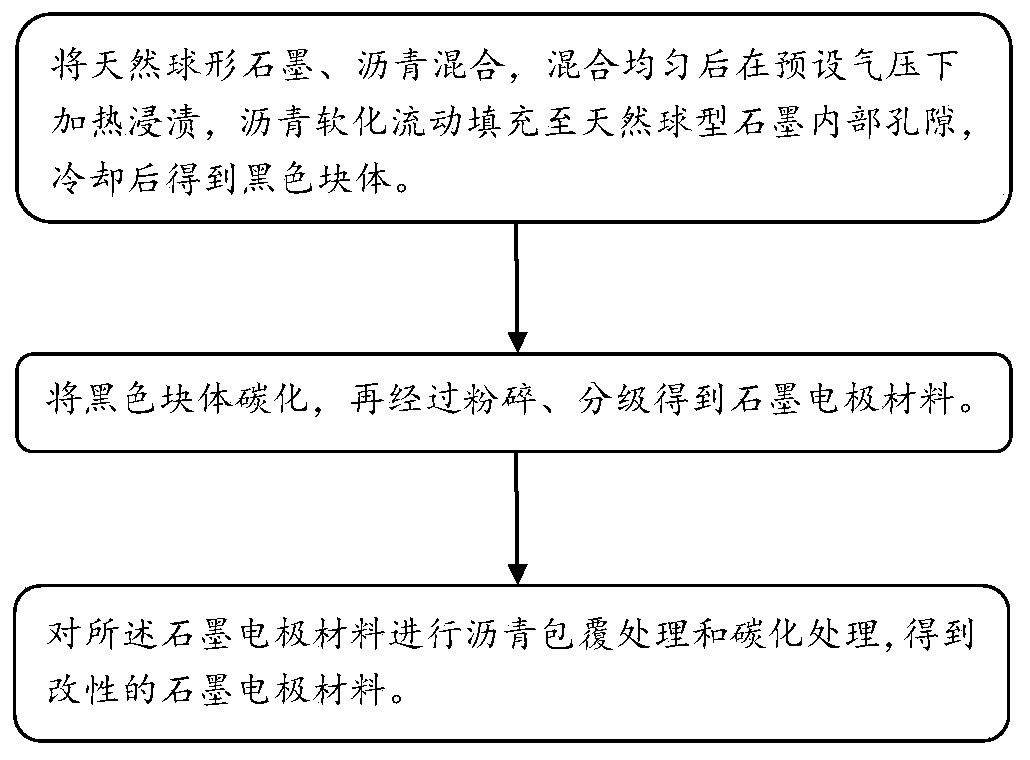

[0029] see figure 1 , the present invention provides a kind of preparation method of soft carbon graphite composite negative electrode material, described soft carbon graphite composite negative electrode material is mainly used in the lithium ion battery (not shown in figure), and it comprises the steps:

[0030] Step S1, mixing natural spherical graphite and pitch, mixing evenly, heating and impregnating under a preset pressure, the pitch softens and flows to fill the internal pores of the natural spherical graphite, and obtains an intermediate product after cooling.

[0031] Specifically, first weigh the natural spherical graphite and powdered pitch and mix, then put the mixture into the reactor for sealing and pressure-holding heating, the pitch is converted into a fluid at high temperature, impregnate the natural spherical graphite, and flow fill it to the natural spherical graphite After impregnating for a period of time, the internal pores are cooled to obtain an interm...

Embodiment 1

[0047]The natural spherical graphite with an average particle size of 8.6um and powdered impregnated pitch (0.5% quinoline insoluble content) are mixed together at a mass ratio of 1:1, then added to the reactor, and the reactor is sealed and heated at 3°C Raise the temperature to 300°C per minute, keep the temperature constant for 2 hours, and keep the pressure at 0.2MPa, then take out the sample, and put it into the furnace for carbonization after the sample is cooled. The carbonized sample was pulverized and classified to obtain a graphite sample with an average particle size of 10.6um. The surface of the graphite sample was coated with 2% by mass of petroleum pitch by means of spray drying, and then carbonized at 1100°C under a nitrogen atmosphere to obtain a composite material.

[0048] Capacity and efficiency test: The composite negative electrode material obtained in Example 1, CMC, and SBR were evenly mixed in a mass ratio of 96.5:1.5:2, then coated on a copper foil cur...

Embodiment 2

[0052] Mix natural spherical graphite with an average particle size of 3.5um and powdered impregnated pitch (0.5% quinoline insoluble matter content) at a mass ratio of 1:1, then add to the reactor, seal the reactor, and heat at 3°C Raise the temperature to 350°C per minute, keep the temperature constant for 2 hours, and keep the pressure at 0.4MPa, then take out the sample, and put it into the furnace for carbonization after the sample is cooled. The carbonized sample was pulverized and classified to obtain a graphite sample with an average particle size of 5.8um. The surface of the graphite sample was coated with 2% mass ratio of coal tar pitch by spray drying, and then carbonized at 1000°C under a mixed gas atmosphere of nitrogen and helium to obtain a composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap