Flanged gasket

A flange sealing and gasket technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., to achieve the effect of avoiding processing steps and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

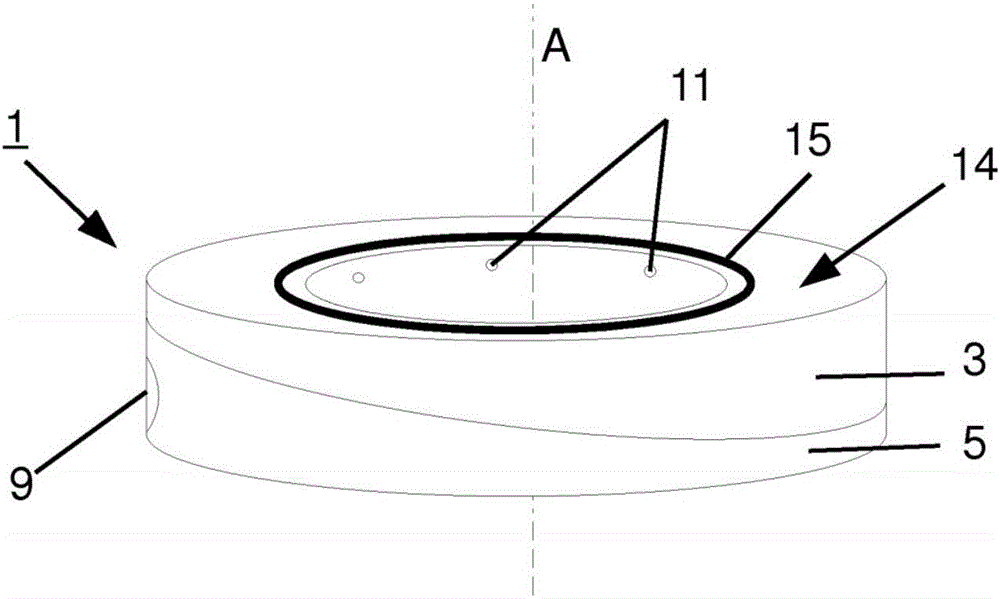

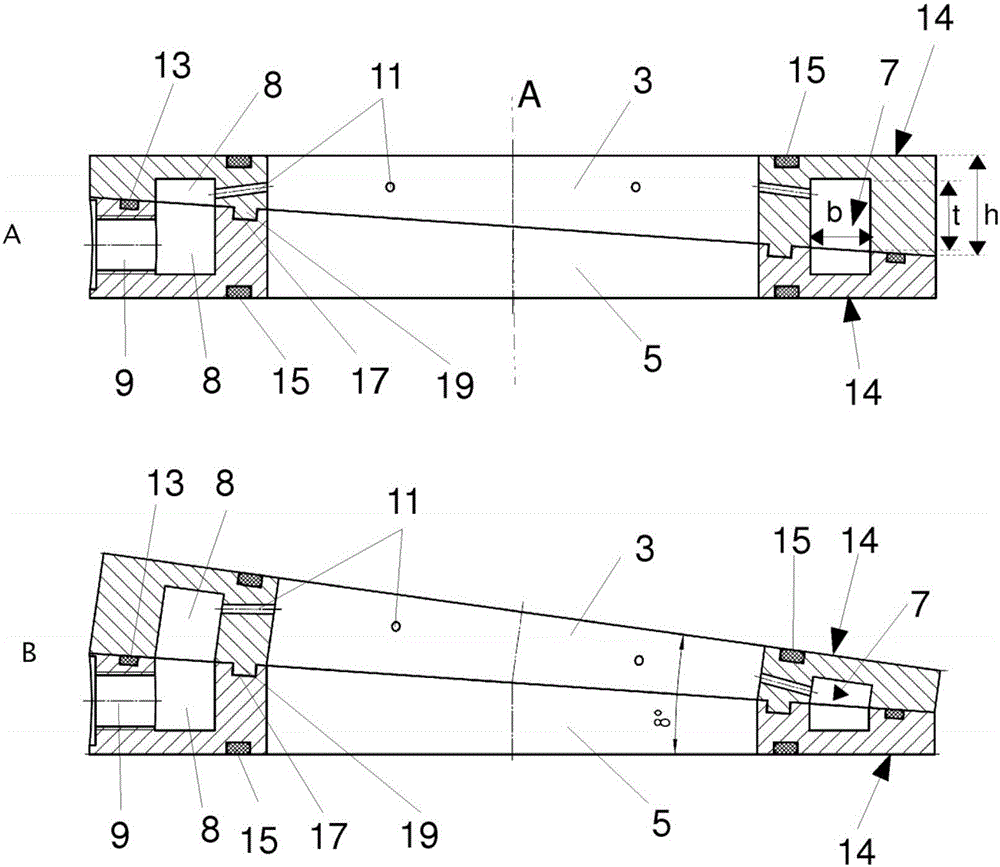

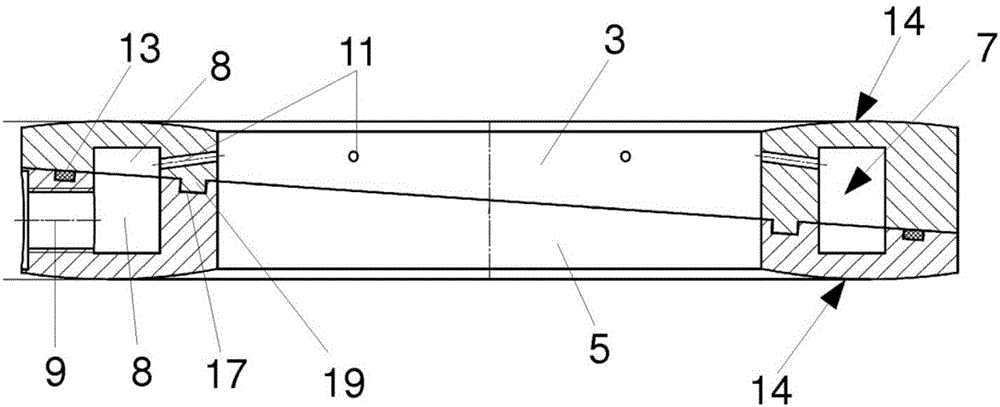

[0036] figure 1 A perspective view of a first embodiment of the flange gasket 1 is shown. The flange gasket 1 is composed of a first ring 3 and a second ring 5 which correspond to each other and are formed in a wedge shape. The first ring 3 and the second ring 5 are arranged concentrically with each other and adjoin each other on substantially flat surfaces at sides facing each other, whereby they can be connected torsionally relative to each other.

[0037] In the second ring 5 there is provided an inlet 9 which is here formed as a bore and opens towards the annular channel 7 formed between the first ring 3 and the second ring 5 . The first ring 3 has a plurality of openings 11 on the inside, which are likewise formed here as bores. The opening 11 is likewise open towards the annular channel 7 , so that fluid is fed into the annular channel 7 via the inlet 9 and can be discharged via the opening 11 . Optionally, a non-return valve 10 can be provided in the inlet 9 in order...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com