Control device for leading and lowering greenhouse melon vines

A technology of control devices and greenhouses, applied in horticulture, botany equipment and methods, plant support, etc., can solve the problems of high physical exertion, high labor intensity, and many labors, so as to reduce labor intensity, improve work efficiency, and manage risks and cost reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

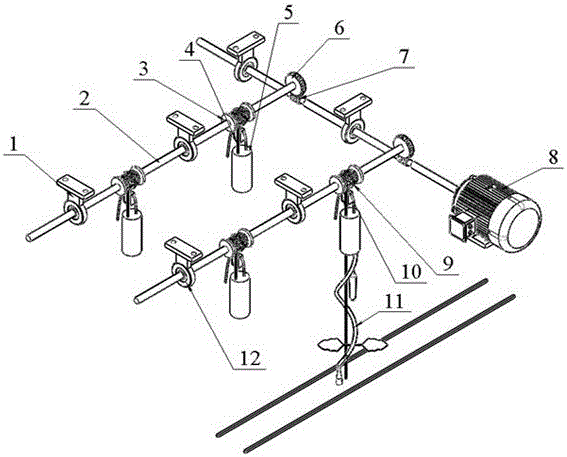

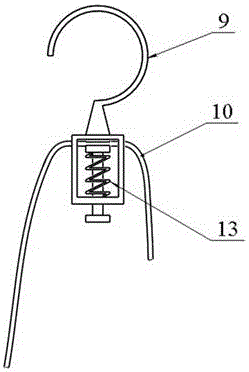

[0018] see figure 1 and figure 2 The growth height and direction control device of the greenhouse cucumber vines in the present invention includes a cross bar 2, a turbine 6, a worm 7 and a drive motor 8, and the drive motor 8 can drive the worm 7 to rotate. The worm gear 6 at the end of the rod 2 is meshed with the worm 7 in a vertical direction, and the worm 7 is provided with a structure at a position corresponding to the turbine 6 to facilitate the meshing connection.

[0019] The worm 7 passes through the bearing 12 and is fixed on the side wall of the greenhouse along the length direction through the fixed connector 1 , and the cross bar 2 is fixed on the top support of the greenhouse through the bearing 12 through the fixed connector 1 . The bearing adopts a ball bearing, and the relative rotation of the cross bar can be easily realized by using the ball bearing.

[0020] The position corresponding to the actual spacing between the melons and vines on the cross bar 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com