Automatic fiber plate cutting edge material recycling and regenerating machine and fiber regenerating method

A technology for automatic recycling and trimming of edge materials, applied in the field of sheet metal processing, can solve the problems of high labor intensity, many labor and high cost, and achieve the effects of low maintenance cost, convenient maintenance and easy installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

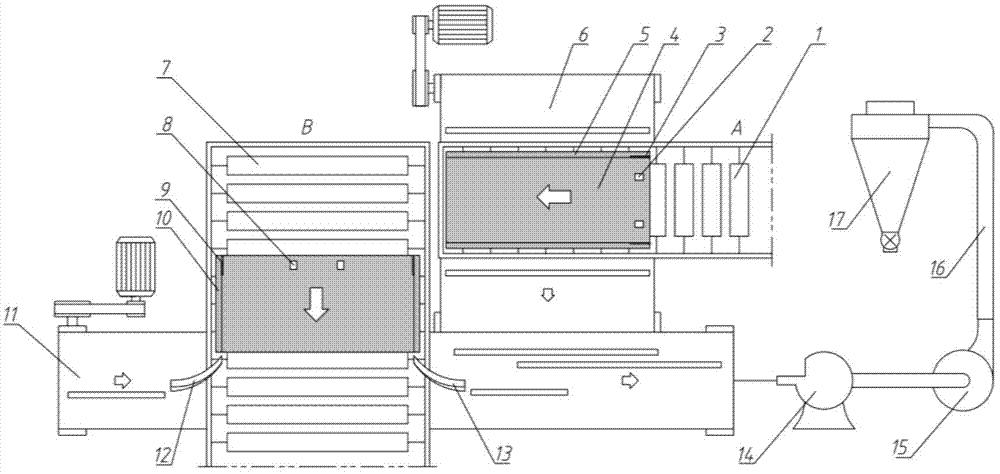

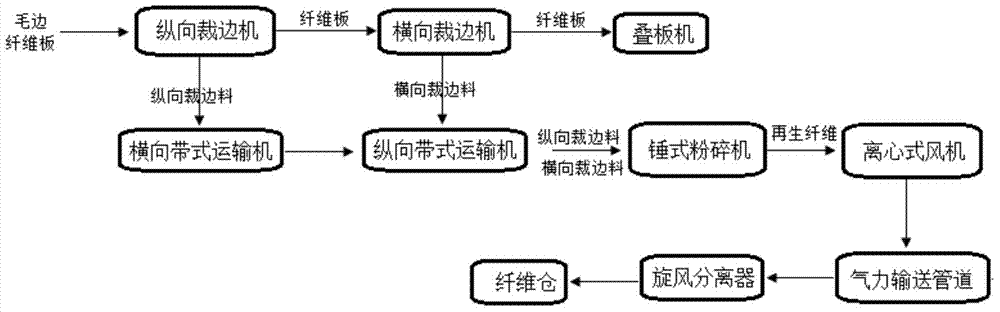

[0029] Such as figure 1 Shown, a kind of fibreboard trimming material automatic recovery regeneration machine, comprises longitudinal trimming machine A, horizontal trimming machine B, transverse belt conveyer 6, longitudinal belt conveyer 11, and successively connected hammer mill 14, Centrifugal blower fan 15, pneumatic conveying pipeline 16 and cyclone separator 17; Described horizontal belt conveyer 6 is installed under the vertical trimming machine A; Described longitudinal belt conveyor 11 is installed below the horizontal trimming machine B The output end of the horizontal belt conveyor 6 extends to the top of the vertical belt conveyor 11; the output end of the vertical belt conveyor 11 extends to the feed inlet of the hammer mill 14;

[0030] After the fiberboard 4 cuts out the longitudinal trimming material 5 on the longitudinal trimming machine A, it enters the horizontal trimming machine B and cuts out the horizontal trimming material 10; The horizontal belt conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com