Railway tunnel large-section steel bar hanging and distributing integrated trolley

A technology with large cross-section and steel bars, applied in tunnels, tunnel linings, shaft equipment, etc., can solve problems such as difficulty in guaranteeing construction quality, large number of construction workers, adjusting the height of side plates on both sides of the platform, etc., to reduce tunnel defects Remediation costs, reducing labor intensity, and solving the effect of excessive labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with embodiment and accompanying drawing, the present invention will be further described. Apparently, the described embodiments are some, but not all, embodiments of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative efforts fall within the protection scope of the present invention.

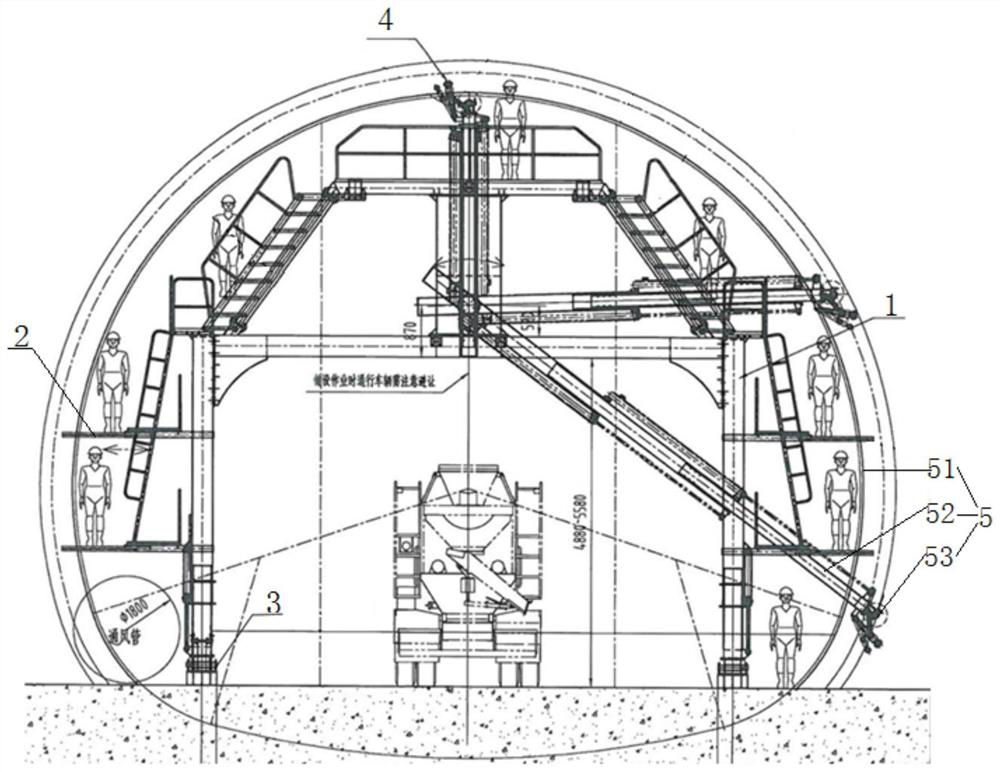

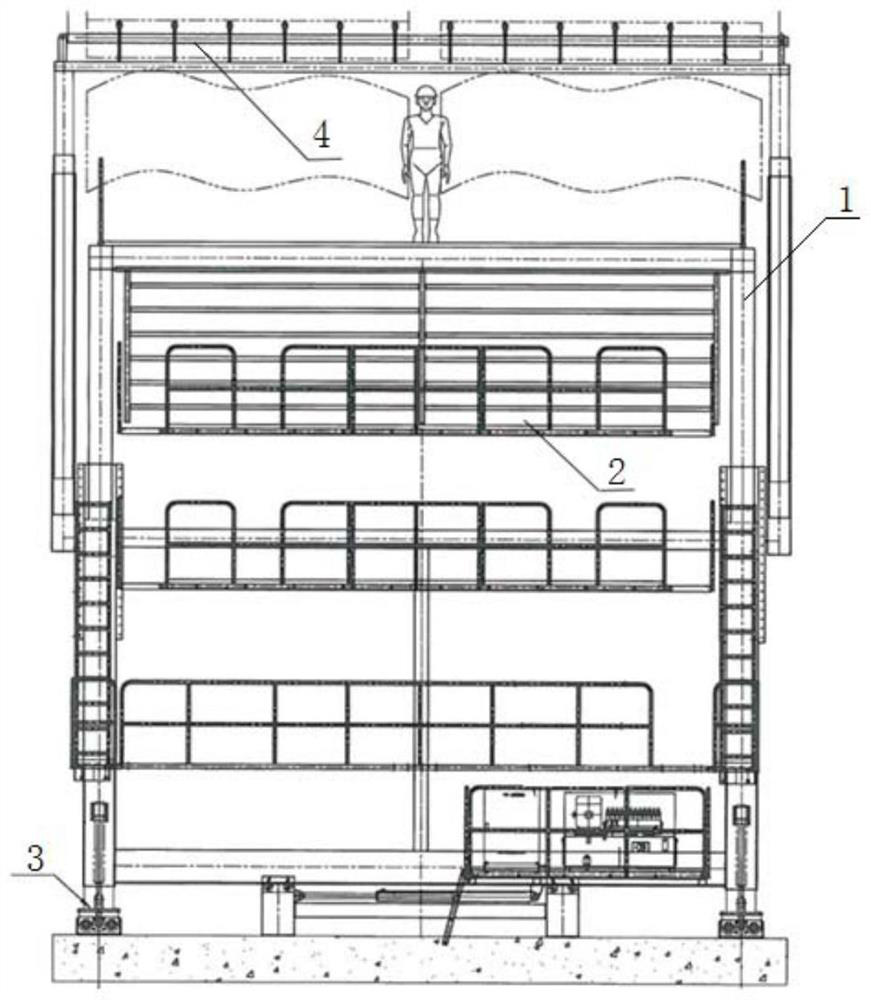

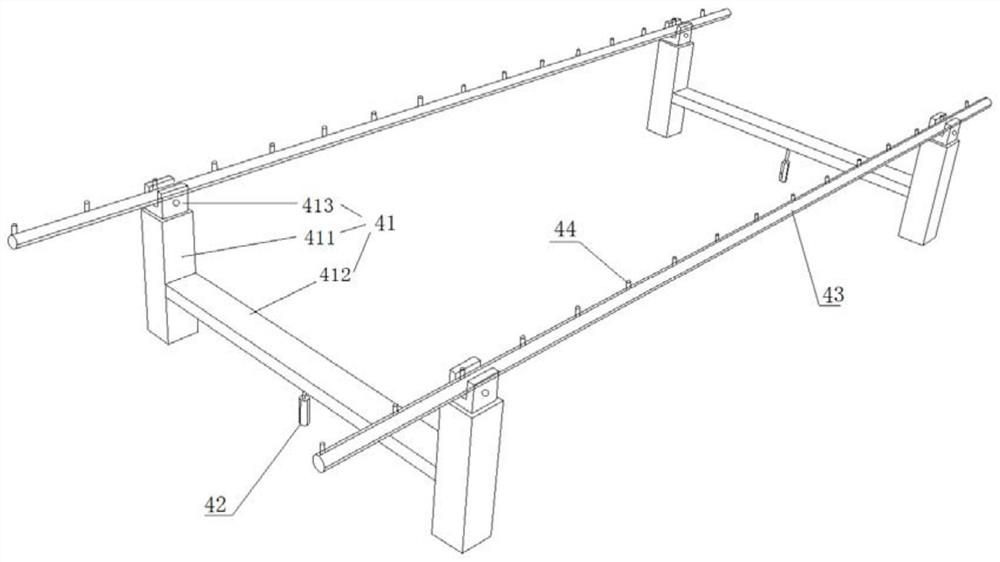

[0020] refer to Figure 1-Figure 2 , a trolley integrated with large cross-section reinforcement and hanging cloth for railway tunnels, including a mast 1, the mast is mainly composed of beams, longitudinal beams, outriggers, columns, diagonal braces, etc., and is mainly spliced by I-beams, with a span of 1950mm, light materials are used to reduce weight; the door frame is connected by bolts and flanges, which is easy to install and disassemble, and can be reused. The minimum width of the mast passing the vehicle is 5750mm, and the height is 4890mm, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com