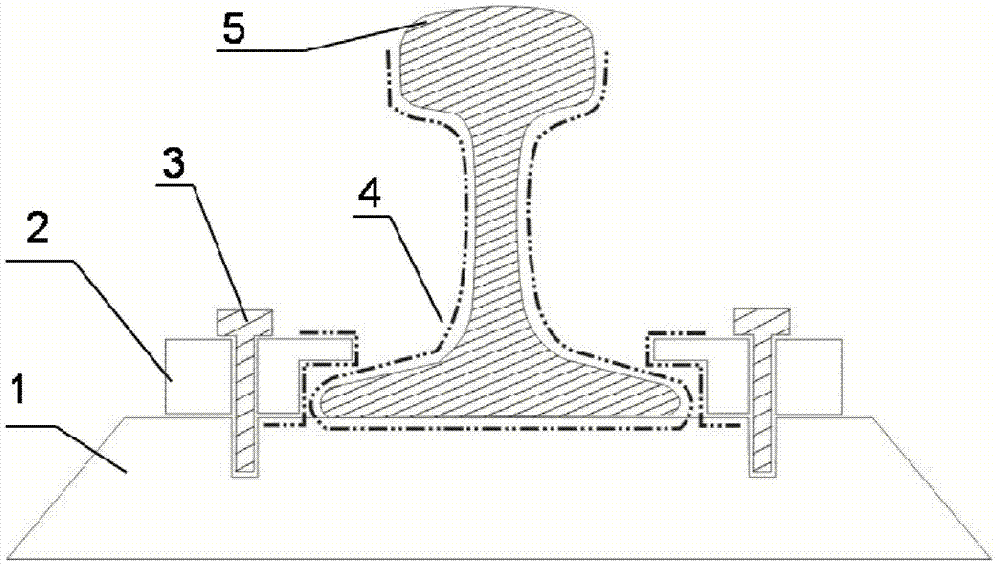

Heavy anticorrosive insulated conversion film and leakage improvement method of track circuit ballast bed

A track circuit, heavy-duty anti-corrosion technology, applied in anti-corrosion coatings, coatings, epoxy resin coatings, etc., can solve problems such as unsustainable maintenance, unbalanced cost-effectiveness, and impact on operation safety, achieving long-lasting effects, strong metal bonding, The effect of improving reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Film-forming material and abrasive wear prestressing process:

[0037] According to the mass fraction, 15% epoxy resin, 28% coal tar pitch liquid and 15% polyurethane are combined into a polymer material matrix, and the surface stress preset is matched with the abrasive wear and rust removal of rail 5, Maximum van der Waals bonds are obtained under hydrolytic conditions.

[0038] (2) Multifunctional packing and environmental surface coating process of rails:

[0039] Add antirust and extender pigments with a mass fraction of 26% to the above matrix to improve the performance of the conversion coating. Anti-rust and extender pigments include aluminum powder, barium metaborate and barium sulfate; especially seek the characteristics that the electrode potential of aluminum is lower than that of iron, and can be replaced by metal salt (Fe 3 o 4 ) is deposited in the active anode area, retarding the anode reaction and inhibiting the oxidation and corrosion of rail ste...

Embodiment 2

[0043] (1) Film-forming material and abrasive wear prestressing process:

[0044] According to the mass fraction, 28% epoxy resin, 15% coal tar pitch liquid and 28% polyurethane are combined into a polymer material matrix, and the surface stress preset is matched with the abrasive wear and rust removal of rail 5, Maximum van der Waals bonds are obtained under hydrolytic conditions.

[0045] (2) Multifunctional packing and environmental surface coating process of rails:

[0046] Add antirust and extender pigments with a mass fraction of 16% to the above matrix to improve the performance of the conversion film. Anti-rust and extender pigments include aluminum powder, barium metaborate and barium sulfate; especially seek the characteristics that the electrode potential of aluminum is lower than that of iron, and can be replaced by metal salt (Fe 3 o 4) is deposited in the active anode area, retarding the anode reaction and inhibiting the oxidation and corrosion of rail steel. ...

Embodiment 3

[0050] (1) Film-forming material and abrasive wear prestressing process:

[0051] According to the mass fraction, 22% epoxy resin, 26% coal tar pitch liquid and 19% polyurethane are combined into a polymer material matrix, and the surface stress preset is matched with the abrasive wear and rust removal of rail 5, Maximum van der Waals bonds are obtained under hydrolytic conditions.

[0052] (2) Multifunctional packing and environmental surface coating process of rails:

[0053] Add antirust and extender pigments with a mass fraction of 21% to the above matrix to improve the performance of the conversion coating. Anti-rust and extender pigments include aluminum powder, barium metaborate and barium sulfate; especially seek the characteristics that the electrode potential of aluminum is lower than that of iron, and can be replaced by metal salt (Fe 3 o 4 ) is deposited in the active anode area, retarding the anode reaction and inhibiting the oxidation and corrosion of rail ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com